Compression Packing

- Home

- Joint Sealant

- Compression Packing

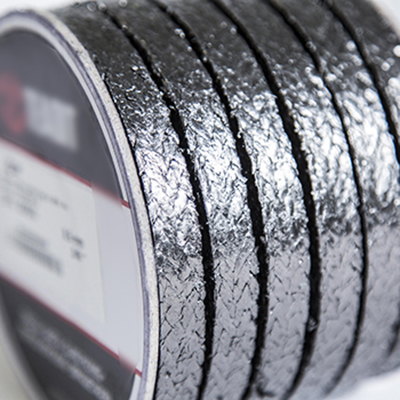

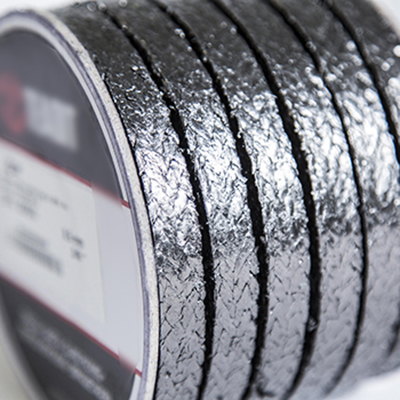

2000

Braided Packing, Flexible Tape. The outstanding properties of this style make it a truly multi-service packing capable of a wide variety of uses throughout a plant. This style may be used in valves, pumps, expansion joints, mixers and agitators in the hostile environments of hydrocarbon processing, pulp and paper, power generation, metal-working and other industries where effective sealing is vital.

2001

Braided Packing Graphite Yarn, Graphite Filled. Style 2001 packing is ideally suited for use in severe service valves and rotary shaft applications. It handles strong acids and alkali solutions except fuming nitric acid, oleum and fluorine. It can be used to seal steam, water, oil, solvents, alkalis, and acids. It is often used as end rings for packing sets utilizing softer packings that might tend to extrude. This style also handles high temperatures, extremely high shaft speeds, most strong chemicals, and reduces shaft wear.

2000-IC

Braided Packing Flexible Graphite, Wire Reinforced. Style 2000IC packing is particularly suited for use in high temperature, high pressure steam service. In addition, it can also handle most chemicals, acids and alkalis. This style is excellent for use in steam turbines, high temperature motor-actuated valves and for high pressure/high temperature valve applications in general

2001-I

Braided Packing Graphite Yarn, Graphite Filled, Wire Reinforced. Style 2001I packing is particularly suited for use in high temperature, high pressure steam service. In addition, it can handle most chemicals, acids and alkalies. This style is excellent for use in steam turbines, high temperature motor-actuated valves and for high pressure, high temperature valve applications in general.

2002

Braided Packing Carbon Yarn, Graphite Filled. Style 2002 handles water, steam, boiler feed, and aqueous solutions of acids and alkalis. In service, it seats quickly and does not require extensive break-in adjustments. This style is commonly used for high speed pumps, blowers, dryers, high temperature valves, and furnace gasketing.

2002-I

Braided Packing Carbon Yarn, Graphite Filled, Wire Reinforced. Style 2002I handles water, steam, boiler feed, and aqueous solutions of acids and alkalis. In service, it seats quickly and does not require extensive break-in adjustments. This style is commonly used in steam turbines, high temperature motor-actuated valves and for high pressure, high temperature valve applications in general.

2007

Braided Packing Expanded PTFE / Graphite. Style 2007 is chemically inert over the entire 0-14 pH range with these exceptions: molten alkali metals, fluoride, aleum, fuming nitric acid, aqua regia, and other strong oxidizing agents.

2017

Expanded PTFE /Graphite with Aramid Corners. Style 2017 packing can handle a broad range of chemicals in the 3-11 pH range. It is used in papermill stock pumps, agitators, or any service where high strength and good lubricating qualities are needed.

2022

Extruded PTFE / Graphite. Style 2022 packing can handle water, steam, oil, solvents, acids and alkalis and can be used for abrasive sludge applications. It is particularly suitable for use in centrifugal pumps, valves, mixers and agitators.

2043

Braided Packing Spun Aramid Yarn, Graphited and Lubricated. Style 2043 is a durable packing able to withstand granular and abrasive applications. It is recommended for service in superheated steam, slurries, petroleum derivatives, solvents, chemicals, liquefied gases, pulp and paper stocks, sugar syrups, and other abrasive fluids.

2070

Expanded PTFE / Graphite Yarn with a Kevlar Core. Style 2070 is a superior general service and corrosive service packing. Its high resistance to extrusion (four times higher than conventional PTFE/graphite packings) makes Style 2070 ideal for handling chemically aggressive fluids in high surface speed and high pressure applications.

2103-T

Braided Packing Carbon Yarn, PTFE Impregnated. Style 2103t packing can handle chemicals over the entire 0-14 pH range except for strong oxidizers. It is very popular in the pulp and paper industry because it is especially designed for applications involving strong caustics, acids, bleaches, slurries, and services where contamination cannot be tolerated. This style is commonly used in valves and pumps, agitators, reactors, and autoclaves.

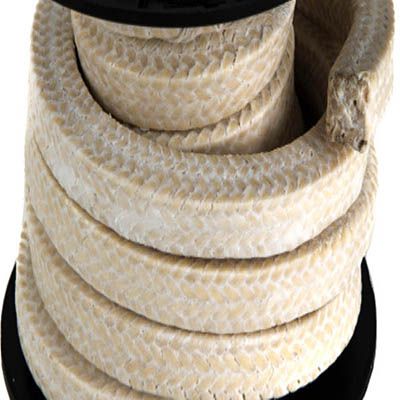

2138

Braided Packing Ramie Yarn, Paraffin impregnated. Style 2138 is a well lubricated, medium-hard packing with extremely low frictional characteristics, which assure minimal shaft wear. The ramie yarn is rot and mildew resistant, making the packing ideal for marine use, handling cold water, salt water, and cold oils. In the marine industry, it is commonly used in stern tubes, rudder posts, and tail shaft liners. This style is also used in the pulp and paper, waste/wastewater, steel and mining industries.

2177

Braided Packing Ramie Yarn, Graphited. Style 2177 is a well lubricated, medium-hard packing with very low frictional characteristics, which assure minimal shaft wear. The ramie yarn is rot and mildew resistant, making the packing ideal for marine use, handling cold water, salt water, and cold oils. In the marine industry it is commonly used in stern tubes, rudder posts, and tail shaft liners. This style packing is also used in the pulp and paper, water/wastewater, and mining industries where a softer packing is desired for lower pressure hydraulic applications.

2202

Braided Packing Flexible Graphite with Carbon Corners. Style 2202 This extremely versatile packing can be used in many demanding applications, both dynamic and static. This style packing is particularly suited for high temperature and high pressure service in valves, pumps, expansion joints, mixers and agitators. It can handle most chemicals in the 0-14 pH range with the exception of strong oxidizers.

2214

High Temperature, Non-Asbestos Valve Stem Packing. Style 2214 is a firm, high density, non-asbestos packing. It can handle steam, most chemicals, mild acids, and alkalies. It is excellent for use in steam turbines, high temperature motor-actuated slide valves, and in high pressure/high temperature valving in general.

2255

Braided Packing Synthetic Yarn, Graphited, and Lubricated. Style 2255 is a dense, but flexible general service packing that adapts well to worn or scored shafts often found in older equipment. It assures an excellent seal against steam, brine, oil, and mild acids and alkalis. This style is well-suited for applications in rotary and centrifugal pumps and some valves.

2003

Braided Packing PTFE Yarn, Aramid Corners. Style 2003 packing, with its unique combination of PTFE and aramid fibers, is dimensionally stable, non-contaminating, has excellent lubricating and running characteristics, and because of the aramid corners, is very wear resistant. It handles acids, alkalis, and a broad range of chemicals. It is well suited for service in rotary and reciprocating pumps, mixers, agitators and reactors, especially where abrasive wear is a problem.

2005

Braided Packing PTFE Yarn, Dry. Style 2005 is similar to Style 2006S, but is especially suited for oxygen service and other services where lubricants other than PTFE can not be tolerated. Style 2005 is commonly used in valves and lower shaft speed applications. It is resistant to most chemicals, aggressive fluids, gases and solvents, with the exception of molten alkali metals.

2007

Braided Packing Expanded PTFE / Graphite. Style 2007 is chemically inert over the entire 0-14 pH range with these exceptions: molten alkali metals, fluoride, aleum, fuming nitric acid, aqua regia, and other strong oxidizing agents.

2017

Expanded PTFE /Graphite With Aramid Corners. Style 2017 packing can handle a broad range of chemicals in the 3-11 pH range. It is used in papermill stock pumps, agitators, or any service where high strength and good lubricating qualities are needed.

2018

Braided Packing Synthetic Yarn with PTFE, Dry. Style 2018 is a good general service packing with no lubricant. It can handle a broad range of chemicals in the 3-11 pH range, and is white in color so it will not discolor flow media. This style is typically used in valves and slow speed pumps where contamination from break-in lubricants cannot be tolerated.

2019

Braided Packing Synthetic Yarn with PTFE, Lubricated. Style 2019 is an excellent multi-service packing that finds a wide variety of uses throughout a plant. It handles steam, water, solvents, oils, mild acids and alkalies, and a broad range of other chemicals. It is white in color and will not discolor the flow media. This style is recommended for use in centrifugal, rotary and reciprocating pumps and also mixers, agitators, and expansion joints.

2022

Extruded PTFE / Graphite. Style 2022 packing can handle water, steam, oil, solvents, acids and alkalis and can be used for abrasive sludge applications. It is particularly suitable for use in centrifugal pumps, valves, mixers and agitators.

2024

Extruded Pure PTFE. Style 2024 packing can handle water, steam, oil, solvents, acids and alkalis and can be used with clear fluids or abrasive sludge. It is particularly suitable for use in centrifugal pumps, valves, mixers, agitators and for sealing dome lids.

2030

DuPont Nomex with PTFE and Mineral Oil. The high mechanical strength of the NOMEX fibre, combined with the elaborate braiding process, results in a soft and pliable packing with excellent mechanical and chemical resistance. Because of the low coefficient of friction, shaft wear is largely avoided, even at high shaft speeds. No excessive heat build-up between the packing rings and the turning shaft; the packing runs cool, remains soft and flexible, resulting in longer service life.

2044

Braided Packing Spun Aramid Yarn, PTFE Impregnated. Style 2044 is a durable packing able to withstand granular and abrasive applications. It is recommended for service in superheated steam, slurries, petroleum derivatives, solvents, chemicals, liquified gases, pulp and paper stocks, sugar syrups, and other abrasive fluids.

2070

Expanded PTFE / Graphite Yarn with a Kevlar Core. Style 2070 is a superior general service and corrosive service packing. Its high resistance to extrusion (four times higher than conventional PTFE/graphite packings) makes Style 2070 ideal for handling chemically aggressive fluids in high surface speed and high pressure applications.

2103-T

Braided Packing Carbon Yarn, PTFE Impregnated. Style 2103t packing can handle chemicals over the entire 0-14 pH range except for strong oxidizers. It is very popular in the pulp and paper industry because it is especially designed for applications involving strong caustics, acids, bleaches, slurries, and services where contamination cannot be tolerated. This style is commonly used in valves and pumps, agitators, reactors, and autoclaves.

2421

Braided Packing Ramie Yarn, PRFE Impregnated. Style 2421 is a well lubricated, medium-hard packing with very low frictional characteristics, which assures minimal shaft wear. The ramie yarn is rot and mildew resistant, making the packing ideal for marine use, handling cold water, salt water and cold oils. In the marine industry, it is recommended for sealing stern tube and rudder post stuffing boxes. This style is also used for certain pump and valve applications in the pulp and paper, water/wastewater, and mining industries.

2500

Rubber Core with PTFE Wrapping. Style 2500 can be used with all kinds of tank lids, hatches etc. for ships, barges, road- and rail transport vehicles, storage tanks etc. Developed for the carrying of hazardous liquid cargoes and can be used with most chemicals likely to be carried, i.e. chemicals, solvents, acids, alkalis, oils, foodstuffs etc.

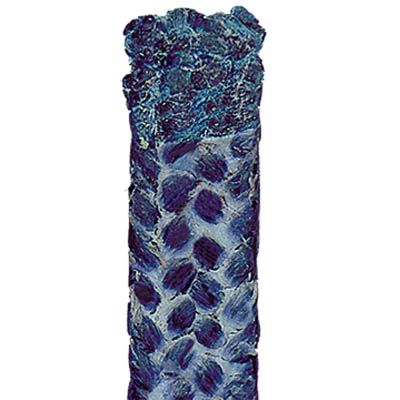

2700

Blue Polyimide with PTFE and Silicone Oil. Style 2700 can be used for demanding applications in rotary and piston pumps, mixers and stirrers, sliders and valves in a wide variety of different industries. It covers a pH-range of 0 - 12 and can be used with water, steam, brine, acids, diluted alkalis, chemicals, solvents, petroleum derivatives etc.

2777

Braided Packing Novoloid Fiber, PTFE Impregnated. Style 2777 packing is a high performance packing that is well suited to applications where graphite impregnation may not be acceptable. It can handle steam, water, acids and other chemical and solvent applications. This style has multiple uses in chemical plants and pulp and paper mills, and is regularly used in rotating and reciprocating pumps, washer journals, liquor pumps, refiners and digesters.

3070

Woven PTFE Gasket Tape. Style 3070 gasket tape is flexible and compresses easily, and gasket extrusion is negligible. It readily conforms to flange irregularities and fills in surface voids even at low flange bolt loads. It handles virtually any chemical service with the exception of molten alkali metals, and can be used in most food processing and pharmaceutical applications.

2004

Braided Packing Aramid Yarn, PTFE Impregnated. Style 2004 is an extremely durable packing able to withstand granular and abrasive applications. It is recommended for service in superheated steam, slurries, petroleum derivatives, solvents and liquified gases. It is commonly used in centrifugal, rotary and reciprocating pumps, agitators and mixers, especially in the paper, steel, petroleum and chemical industries, and in sewage treatment plants.

2017

Expanded PTFE /Graphite With Aramid Corners. Style 2017 packing can handle a broad range of chemicals in the 3-11 pH range. It is used in papermill stock pumps, agitators, or any service where high strength and good lubricating qualities are needed.

2043

Braided Packing Spun Aramid Yarn, Graphited and Lubricated. Style 2043 is a durable packing able to withstand granular and abrasive applications. It is recommended for service in superheated steam, slurries, petroleum derivatives, solvents, chemicals, liquefied gases, pulp and paper stocks, sugar syrups, and other abrasive fluids.

2044

Braided Packing Spun Aramid Yarn, PTFE Impregnated. Style 2044 is a durable packing able to withstand granular and abrasive applications. It is recommended for service in superheated steam, slurries, petroleum derivatives, solvents, chemicals, liquified gases, pulp and paper stocks, sugar syrups, and other abrasive fluids.

2060

Expanded PTFE / Yarn with a Kevlar Core. Style 2060 is a superior general service and corrosive service packing. It is especially suited for applications where contamination cannot be tolerated. Its high resistance to extrusion (four times higher than conventional PTFE/graphite packings) makes Style 2060 ideal for handling chemically aggressive fluids in high pressure applications. It is commonly used in valves, pumps and expansion joints.

2070

Expanded PTFE / Graphite Yarn with a Kevlar Core. Style 2070 is a superior general service and corrosive service packing. Its high resistance to extrusion (four times higher than conventional PTFE/graphite packings) makes Style 2070 ideal for handling chemically aggressive fluids in high surface speed and high pressure applications.

2000

Braided Packing, Flexible Tape. The outstanding properties of this style make it a truly multi-service packing capable of a wide variety of uses throughout a plant. This style may be used in valves, pumps, expansion joints, mixers and agitators in the hostile environments of hydrocarbon processing, pulp and paper, power generation, metal-working and other industries where effective sealing is vital.

2001

Braided Packing Graphite Yarn, Graphite Filled. Style 2001 packing is ideally suited for use in severe service valves and rotary shaft applications. It handles strong acids and alkali solutions except fuming nitric acid, oleum and fluorine. It can be used to seal steam, water, oil, solvents, alkalis, and acids. It is often used as end rings for packing sets utilizing softer packings that might tend to extrude. This style also handles high temperatures, extremely high shaft speeds, most strong chemicals, and reduces shaft wear.