General Rubber

Maxi-Joint® Rubber Expansion Joints

General Rubber’s Maxi-Joint brand represents our state-of-the-art line of rubber expansion joints, flexible connectors, rubber flanged hoses and accessories, as well as spray shields and penetration seals. Since our inception in 1950, General Rubber has designed and developed a wide range of performance products used in the most demanding applications. Improved performance and engineered solutions are accomplished by incorporating advanced materials of construction and technologies to what otherwise would be considered a conventional product line.

Piping and ducting systems require support and flexibility as critical design elements to ensure continuous and safe operation. The features and benefits of our performance expansion joint designs will achieve these critical elements by absorbing system forces and displacements, replacing them with the expansion joint’s low stiffness (spring rate).

Additionally, they are designed to reduce noise and vibration, have a cycle life in the tens of millions, compensate for misalignments, provide access to piping and equipment, and relieve pipe and anchor stresses.

The selection and application of General Rubber’s unrestrained expansion joints represent the most cost-effective arrangement when they are used in rigid piping systems with main anchors and numerous guides at specific spacing.

The selection and application of General Rubber’s advanced restrained expansion joints can be used to provide system flexibility while restraining pressure thrust forces and other external loads. This approach allows for an optimal design with a smaller footprint. The economic benefits of using advanced restrained expansion joints also include—but are not limited to—fewer guides, anchors and supports.

Piping Expansion Joints

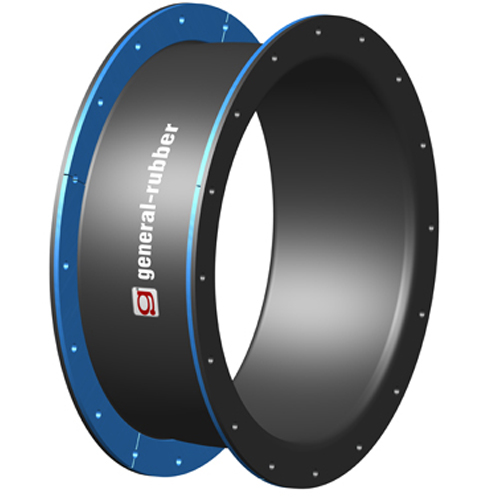

Single Wide Arch Style 1101

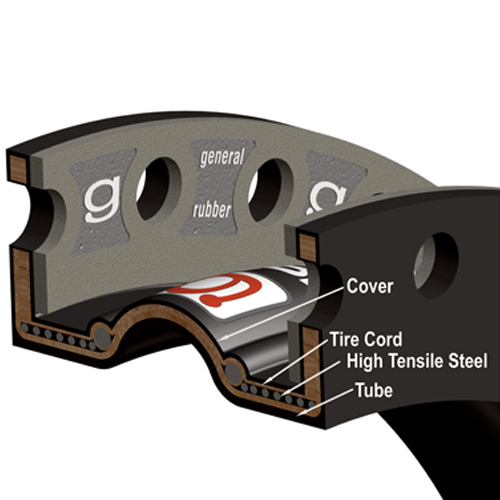

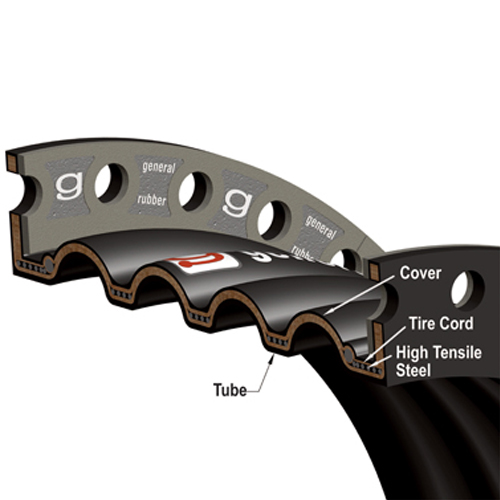

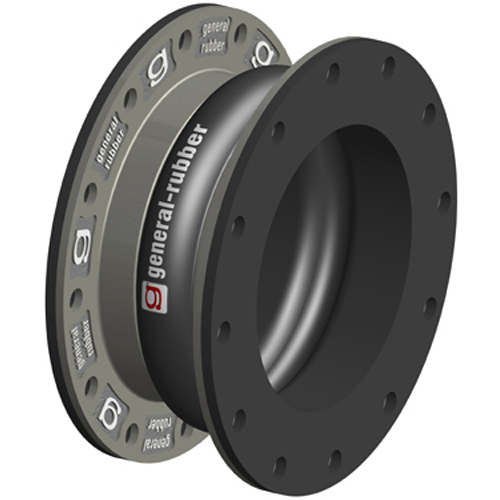

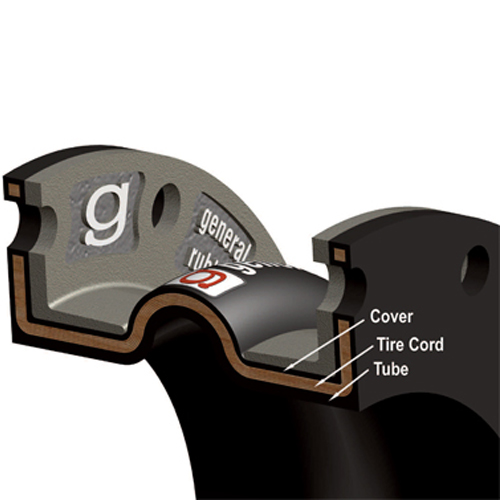

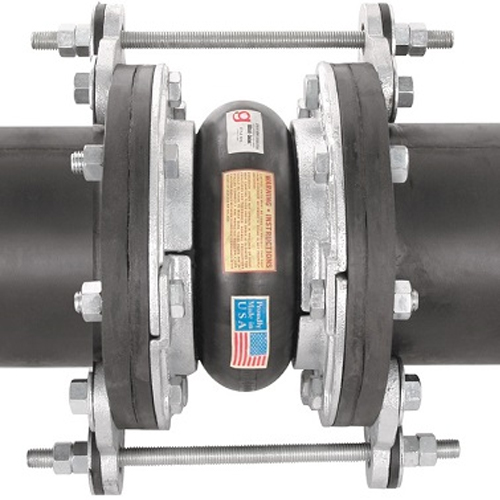

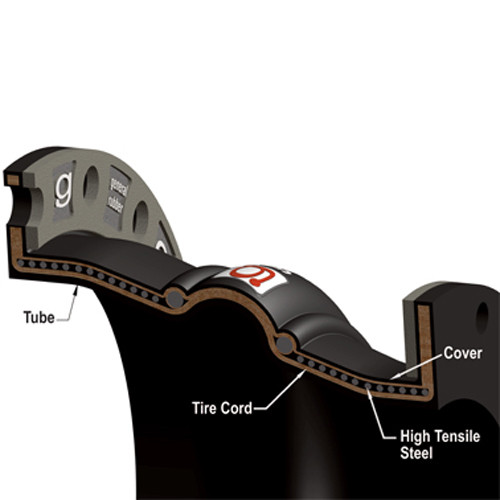

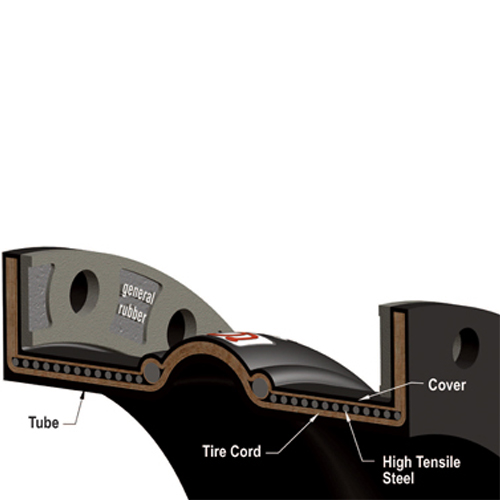

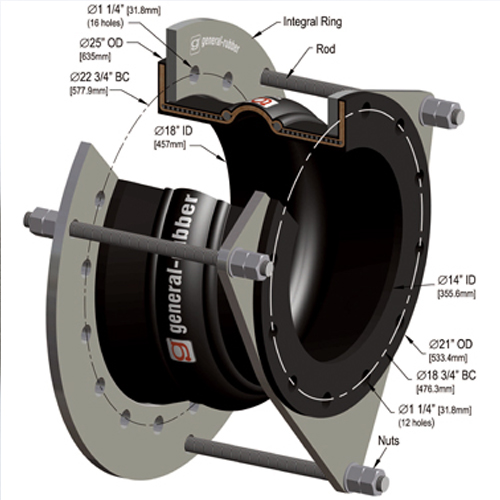

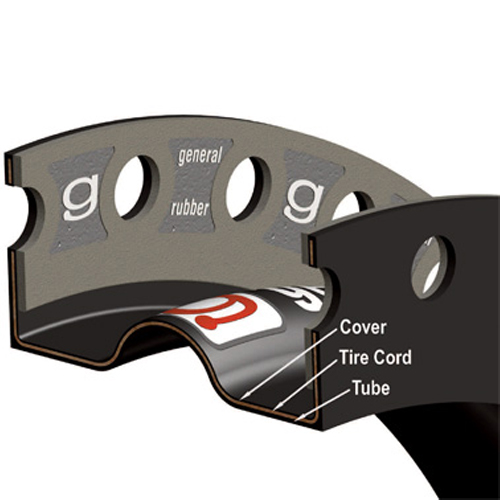

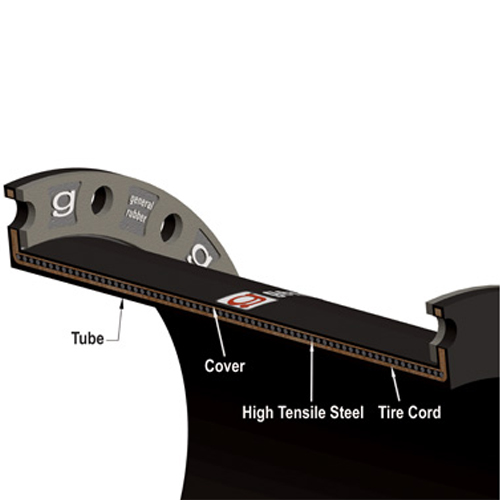

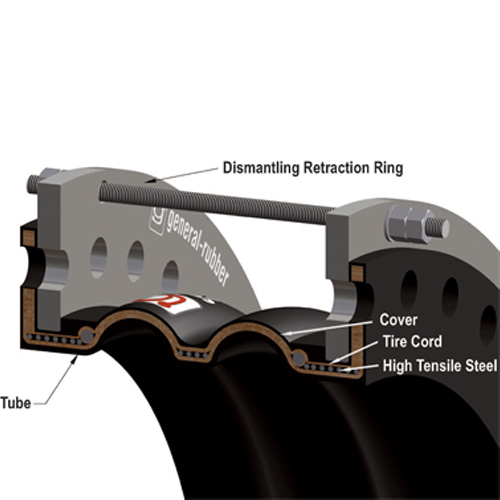

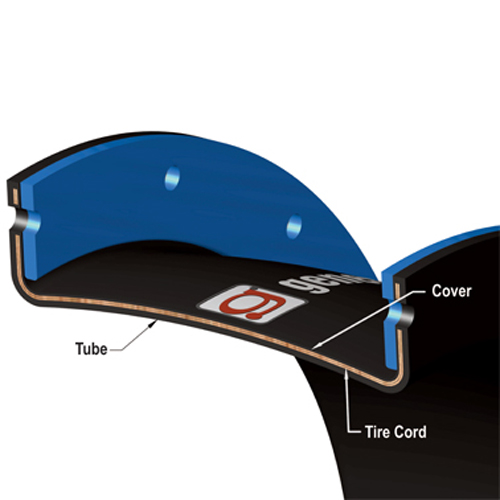

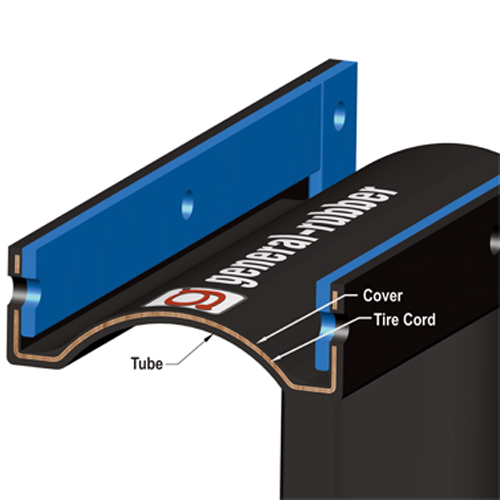

General Rubber's Style 1101 single (1) wide arch rubber expansion joints are designed to absorb large all-directional movements, reduce noise and vibration, have a cycle life in the tens of millions, compensate for misalignments, provide access to piping and equipment and relieve pipe and anchor stresses. Its spool type body is constructed with full rubber flanges, a high-grade leak-proof tube, multiple layers of high-strength tire cord, high tensile steel reinforcement, a seamless cover, and hot dip galvanized steel retaining rings. This construction, as a standalone expansion joint, represents the most cost-effective arrangement when used in rigid piping systems with main anchors (MA) and numerous guides at specific spacing. Control units can be externally or internally attached and used as limit rods for secondary restraint, or as tie rods when the support structure or adjacent equipment have load limitations.

Features

- Standard or custom face-to-face dimensions

- Wide flowing arch design

- Exceptional all directional movement capability

- Virtually eliminates sediment buildup

- Absorbs noise, vibration and shock

- Higher pressure rating than conventional expansion joints

- Hot dip galvanized retaining rings standard

- Other standard drilling available, including ASA 300, DIN, PN, JIS, API, and Navy

- Excellent chemical and abrasion resistance

- Full vacuum rating (30" Hg) for style 1202

- 250°F continuous service standard (400°F available)

- Compensates for minor misalignment and offset

- Low stiffness and deflection forces

- Integrally flanged design, no gaskets required

- Simple to install and high strength

- Provides easy access to piping and equipment

- Filled arch design available

TECHNICAL RESOURCES

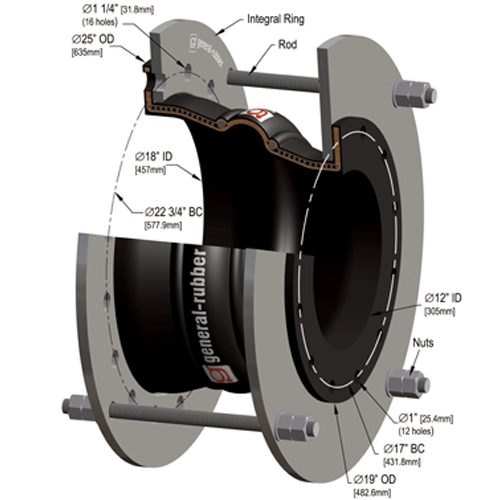

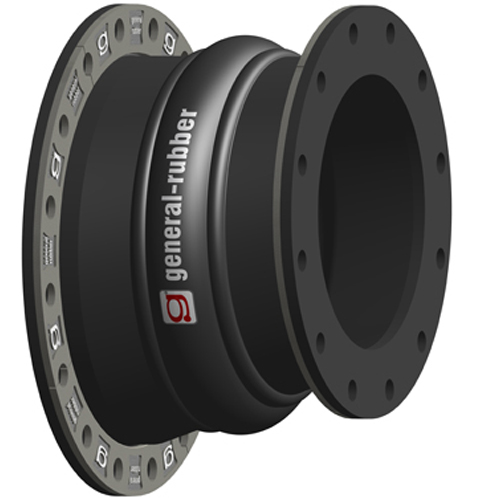

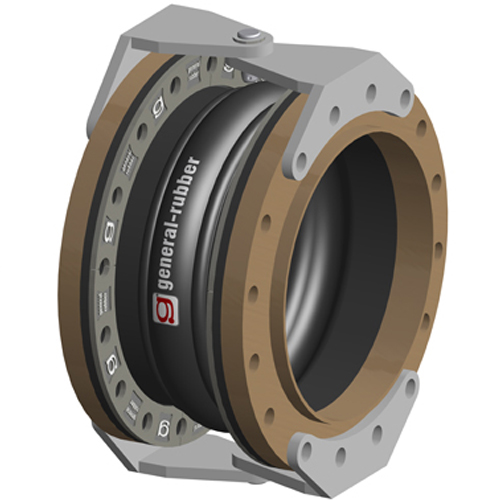

Double Wide Arch Style 1102

General Rubber's Styles 1102 and 1202, double (2) wide arch rubber expansion joints have twice the all-directional movement capabilities with half the spring rates of our single arch design. Additionally, they are designed to reduce noise and vibration, have a cycle life in the tens of millions, compensate for misalignments, provide access to piping and equipment and relieve pipe and anchor stresses. Its spool type body is constructed with full rubber flanges, a high-grade leak-proof tube, multiple layers of high-strength tire cord, high tensile steel reinforcement, a seamless cover and hot dip galvanized steel retaining rings. This construction, as a standalone expansion joint, represents the most cost-effective arrangement when used in rigid piping systems with main anchors (MA) and numerous guides at specific spacing. Control units can be externally or internally attached and used as limit rods for secondary restraint or as tie rods when the support structure or adjacent equipment have load limitations.

Features

- Versatile hand-built construction

- Double the movement with half the spring rate

- Standard or custom face-to-face dimensions

- Available in custom offset arrangements and sizes not shown

- Virtually eliminates sediment buildup

- Higher pressure rating than conventional expansion joints

- Style 1202 designates full vacuum rating (30" Hg) in all sizes

- 250°F continuous service standard (400°F available)

- Hot dip galvanized retaining rings standard

- Integral flange design, no gaskets required

- Filled arch design available

- High strength and simple to install

TECHNICAL RESOURCES

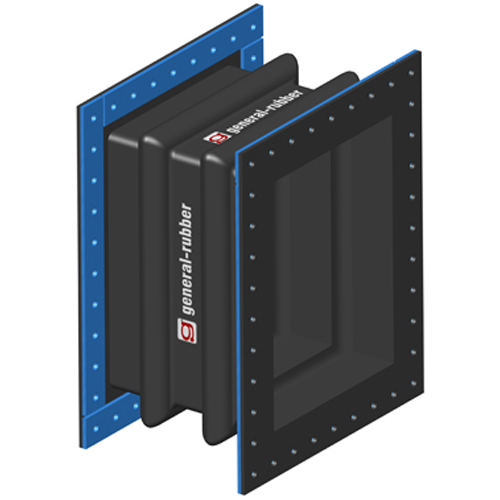

Triple Wide Arch Style 1103

General Rubber's Styles 1103 and 1203, triple (3) wide arch rubber expansion joints have triple the all-directional movement capabilities with one-third the spring rates of our single arch design. Additionally, they are designed to reduce noise and vibration, have a cycle life in the tens of millions, compensate for misalignments, provide access to piping and equipment and relieve pipe and anchor stresses. Its spool type body is constructed with full rubber flanges, a high-grade leak-proof tube, multiple layers of high-strength tire cord, high tensile steel reinforcement, a seamless cover and hot dip galvanized steel retaining rings. This construction, as a standalone expansion joint, represents the most cost-effective arrangement when used in rigid piping systems with main anchors (MA) and numerous guides at specific spacing. Control units can be externally or internally attached and used as limit rods for secondary restraint or as tie rods when the support structure or adjacent equipment have load limitations.

Features

- Versatile hand-built construction

- Triple the movement with one-third the spring rate Triple the movement with one-third the spring rate

- Standard or custom face-to-face dimensions

- Available in custom offset arrangements and sizes not shown

- Virtually eliminates sediment buildup

- Higher pressure rating than conventional expansion joints

- Style 1203 designates full vacuum rating (30" Hg) in all sizes

- 250°F continuous service standard (400°F available)

- Hot dip galvanized retaining rings standard

- Integral flange design, no gaskets required

- Filled arch design available

- High strength and simple to install

TECHNICAL RESOURCES

Quadruple Wide Arch Style 1104

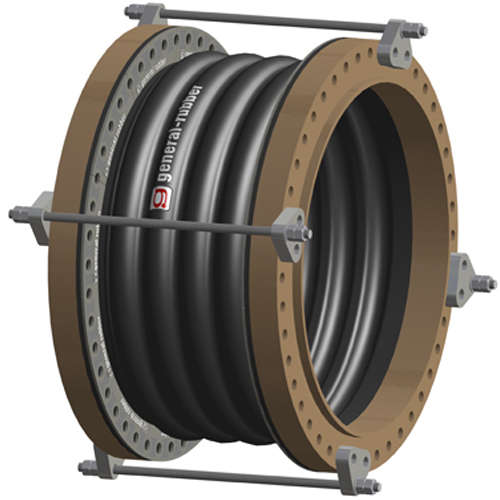

General Rubber's Styles 1104 and 1204, quadruple (4) wide arch rubber expansion joints have quadruple the all directional movement capabilities with one-quarter the spring rates of our single arch design. Additionally, they are designed to reduce noise and vibration, have a cycle life in the tens of millions, compensate for misalignments, provide access to piping and equipment and relieve pipe and anchor stresses. Its spool type body is constructed with full rubber flanges, a high-grade leak-proof tube, multiple layers of high-strength tire cord, high tensile steel reinforcement, a seamless cover and hot dip galvanized steel retaining rings. This construction, as a standalone expansion joint, represents the most cost-effective arrangement when used in rigid piping systems with main anchors (MA) and numerous guides at specific spacing. Control units can be externally or internally attached and used as limit rods for secondary restraint or as tie rods when the support structure or adjacent equipment have load limitations.

Features

- Versatile hand-built construction

- Quadruple the movement with one-quarter the spring rate

- Standard or custom face-to-face dimensions

- Available in custom offset arrangements and sizes not shown

- Virtually eliminates sediment buildup

- Higher pressure rating than conventional expansion joints

- Style 1204 designates full vacuum rating (30" Hg) in all sizes

- 250°F continuous service standard (400°F available)

- Hot dip galvanized retaining rings standard

- Integral flange design, no gaskets required

- Filled arch design available

- High strength and simple to install

TECHNICAL RESOURCES

Economical Single Wide Arch Style 1015

General Rubber's Style 1015 rubber expansion joints represent our most cost-effective full pressure single wide arch design. An optional Teflon liner is available for optimal temperature and chemical resistance. Additionally, they are designed to absorb large all-directional movements, reduce noise and vibration, have a cycle life in the tens of millions, compensate for misalignments, provide access to piping and equipment and relieve pipe and anchor stresses. Its spool type body is constructed with full rubber flanges, a high-grade leak-proof tube, multiple layers of high-strength tire cord, high tensile steel reinforcement, a seamless cover and hot dip galvanized steel retaining rings. This construction, as a standalone expansion joint, represents the most cost-effective arrangement when used in rigid piping systems with main anchors (MA) and numerous guides at specific spacing. Control units can be used as limit rods for secondary restraint or as tie rods when the support structure or adjacent equipment have load limitations.

Features

- Versatile hand-built construction

- Economical fully molded construction

- Virtually eliminates sediment buildup

- Higher pressure rating than conventional expansion joints

- Full vacuum rating (30" Hg) in all sizes

- 250°F continuous service standard (400°F available)

- Hot dip galvanized retaining rings standard

- Integral flange design, no gaskets required

- Filled arch design available

- High strength and simple to install

- Large inventory means quick shipments

TECHNICAL RESOURCES

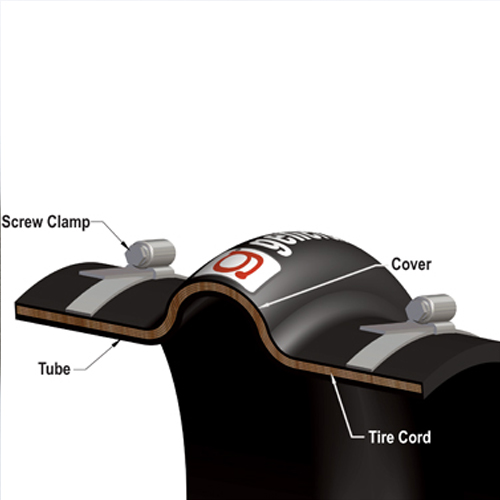

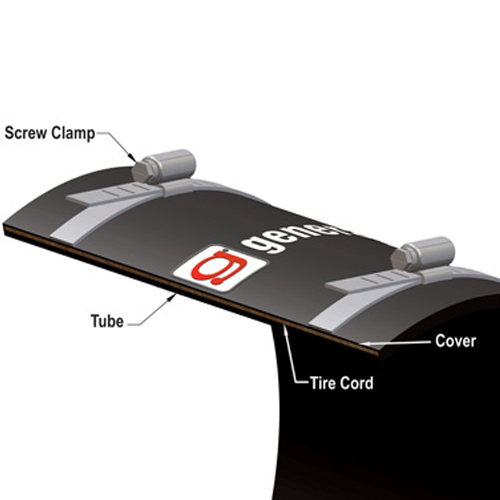

Rubber Slip-On Sleeve Styles 8101, 8102, 8103

General Rubber's Style 8101 single (1) arch sleeve type rubber expansion joints are designed with lower spring rates for reduced reaction forces and greater movement capabilities within a compact body. This optimally designed slip-on and lightweight construction represents the most cost-effective arrangement for low pressure applications. Mating flanges and hardware are not required, adding to the cost-effectiveness of this arrangement. The construction includes a high-grade leak-proof tube, a seamless cover, multiple layers of high-strength tire cord and stainless steel screw clamps. Additionally, they are designed to absorb large all-directional movements, reduce noise and vibration, have a cycle life in the tens of millions, compensate for misalignments, provide access to piping and equipment and relieve pipe and anchor stresses.

General Rubber's Style 8102 double (2) arch sleeve type rubber expansion joints have twice the all-directional movement capabilities with half the spring rates of our single arch design.

General Rubber's Style 8103 triple (3) arch sleeve type rubber expansion joints have triple the all-directional movement capabilities with one-third the spring rates of our single arch design.

Features

- Versatile hand-built construction

- Available in split-wrap or custom offset arrangements and sizes not shown

- Virtually eliminates sediment buildup

- Economical slip-on design eliminates the need for mating flanges and hardware

- Higher pressure rating than conventional expansion joints

- Extremely lightweight and flexible

- 250°F continuous service standard (400°F available)

- Reducers and offset styles available

- Filled arch design available

- High strength and simple to install

TECHNICAL RESOURCES

Concentric Reducing Style 1101CR

General Rubber's Styles 1101CR and 1201CR concentric reducing rubber expansion joints are an economical way to combine a reducing pipe fitting with an expansion joint. The two different flanged diameters have a common centerline. Additionally, they are designed to absorb large all-directional movements, reduce noise and vibration, have a cycle life in the tens of millions, compensate for misalignments, provide access to piping and equipment and relieve pipe and anchor stresses. Its spool type body is constructed with full rubber flanges, a high-grade leak-proof tube, multiple layers of high-strength tire cord, high tensile steel reinforcement, a seamless cover and hot dip galvanized steel retaining rings. This construction, as a standalone expansion joint, represents the most cost-effective arrangement when used in rigid piping systems with main anchors (MA) and numerous guides at specific spacing. Control units can be externally or internally attached and used as limit rods for secondary restraint or as tie rods when the support structure or adjacent equipment have load limitations.

Features

- Versatile hand-built construction

- Virtually eliminates sediment buildup

- An economic and space saving way to combine a reducing pipe fitting with an expansion joint

- Available in split-wrap or custom offset arrangements and sizes not shown

- Standard or custom face-to-face dimensions

- Available in custom offset arrangements and sizes not shown

- Integral flange design, no gaskets required

- Filled arch design available

- 250°F continuous service standard (400°F available)

- Higher pressure rating than conventional expansion joints

- Style 1201CR designates full vacuum rating (30" Hg) in all sizes

- Hot dip galvanized retaining rings standard

- High strength and simple to install

TECHNICAL RESOURCES

Eccentric Reducing Style 1101ER

General Rubber's Styles 1101ER and 1201ER eccentric reducing rubber expansion joints are an economical way to combine a reducing pipe fitting with an expansion joint. The two different flanged diameters have an offset centerline. Additionally, they are designed to absorb large all-directional movements, reduce noise and vibration, have a cycle life in the tens of millions, compensate for misalignments, provide access to piping and equipment and relieve pipe and anchor stresses. Its spool type body is constructed with full rubber flanges, a high-grade leak-proof tube, multiple layers of high-strength tire cord, high tensile steel reinforcement, a seamless cover and hot dip galvanized steel retaining rings. This construction, as a standalone expansion joint, represents the most cost-effective arrangement when used in rigid piping systems with main anchors (MA) and numerous guides at specific spacing. Control units can be externally or internally attached and used as limit rods for secondary restraint or as tie rods when the support structure or adjacent equipment have load limitations.

Features

- Versatile hand-built construction

- Virtually eliminates sediment buildup

- An economic and space saving way to combine a reducing pipe fitting with an expansion joint

- Available in split-wrap or custom offset arrangements and sizes not shown

- Standard or custom face-to-face dimensions

- Available in custom offset arrangements and sizes not shown

- Integral flange design, no gaskets required

- Filled arch design available

- 250°F continuous service standard (400°F available)

- Higher pressure rating than conventional expansion joints

- Style 1201ER designates full vacuum rating (30" Hg) in all sizes

- Hot dip galvanized retaining rings standard

- High strength and simple to install

TECHNICAL RESOURCES

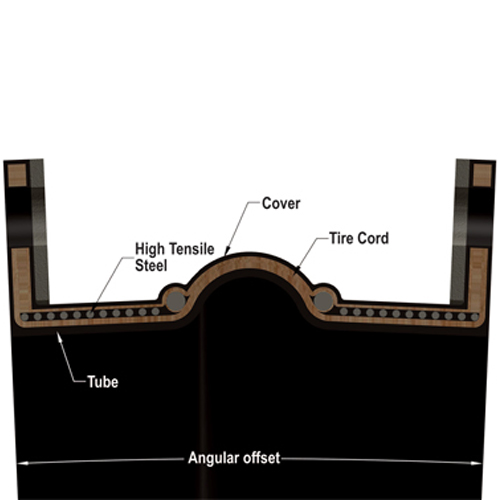

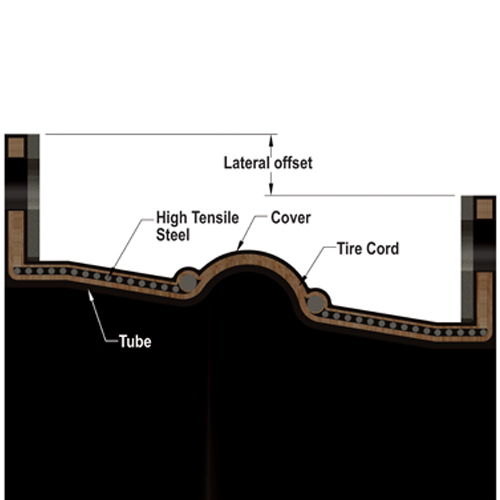

Lateral / Angular Offset 1101LO / 1101AO

General Rubber's Styles 1101AO and 1201AO rubber expansion joints are designed with built-in angular offsets to accommodate non-standard field conditions. They provide ease of installation without compromising any performance capabilities. Additionally, they are designed to absorb large all-directional movements, reduce noise and vibration, have a cycle life in the tens of millions, compensate for misalignments, provide access to piping and equipment and relieve pipe and anchor stresses. Its spool type body is constructed with full rubber flanges, a high-grade leak-proof tube, multiple layers of high-strength tire cord, high tensile steel reinforcement, a seamless cover and hot dip galvanized steel retaining rings. This construction, as a standalone expansion joint, represents the most cost-effective arrangement when used in rigid piping systems with main anchors (MA) and numerous guides at specific spacing. Control units can be externally or internally attached and used as limit rods for secondary restraint or as tie rods when the support structure or adjacent equipment have load limitations.

General Rubber's Styles 1101LO and 1201LO rubber expansion joints are designed with built-in lateral offsets to accommodate non-standard field conditions.

Features

- Versatile hand-built construction

- Virtually eliminates sediment buildup

- An economic and space saving way to combine a reducing pipe fitting with an expansion joint

- Available in split-wrap or custom offset arrangements and sizes not shown

- Standard or custom face-to-face dimensions

- Available in multiple arch arrangements and sizes not shown

- Integral flange design, no gaskets required

- Filled arch design available

- 250°F continuous service standard (400°F available)

- Higher pressure rating than conventional expansion joints

- Styles 1201LO and 1201AO designate full vacuum rating (30" Hg) in all sizes

- Hot dip galvanized retaining rings standard

- High strength and simple to install

TECHNICAL RESOURCES

Lightweight Style 1101LW

General Rubber's Style 1101LW lightweight rubber expansion joints are designed with lower spring rates for reduced reaction forces and greater movement capabilities within a compact body. This optimally designed lightweight construction represents the most cost-effective arrangement for low pressure applications. The construction includes full rubber flanges, a high-grade leak-proof tube, a seamless cover, multiple layers of high-strength tire cord and hot dip galvanized steel retaining rings. Additionally, they are designed to absorb large all-directional movements, reduce noise and vibration, have a cycle life in the tens of millions, compensate for misalignments, provide access to piping and equipment and relieve pipe and anchor stresses.

Features

- Ideal flexible connector for fans, blowers and other industrial OEM Equipment

- High strength and simple to install

- An economic and space saving way to combine a reducing pipe fitting with an expansion joint

- Integral flange design, no gaskets required

- Hot dip galvanized retaining rings standard

- 25 PSIG with 6" Hg standard design

- 250°F continuous service standard (400°F available)

- Virtually eliminates sediment buildup

- Available in multiple arch or offset arrangements and sizes not shown

- Standard or custom face-to-face dimensions

- Versatile hand-built construction

- Extremely flexible design with minimum stiffness and deflection forces

TECHNICAL RESOURCES

High Pressure Style 1101HP

General Rubber's Style 1101HP rubber expansion joints are designed for higher pressure applications. The standard spool type body is reinforced with additional layers of high-strength tire cord and high tensile steel reinforcements. The construction includes full rubber flanges, a high-grade leak-proof tube, a seamless cover and hot dip galvanized steel retaining rings. Additionally, they are designed to reduce noise and vibration, have a cycle life in the tens of millions, compensate for misalignments, provide access to piping and equipment and relieve pipe and anchor stresses. This construction, as a standalone expansion joint, represents the most cost-effective arrangement when used in rigid piping systems with main anchors (MA) and numerous guides at specific spacing. Control units can be externally or internally attached and used as limit rods for secondary restraint or as tie rods when the support structure or adjacent equipment have load limitations.

Features

- Versatile hand-built construction

- Standard or custom face-to-face dimensions

- Available in multiple arches or custom offset arrangements and sizes not shown

- Virtually eliminates sediment buildup

- Higher pressure rating than conventional expansion joints

- Excellent chemical and abrasion resistance

- Full vacuum rating (30" Hg) in all single arch sizes

- 250°F continuous service standard (400°F available)

- Hot dip galvanized retaining rings standard

- Integral flange design, no gaskets required

- Filled arch design available

- High strength and simple to install

TECHNICAL RESOURCES

High Temperature Style 1101HT

General Rubber's Style 1101HT rubber expansion joints are designed for higher temperature applications. The spool type body is constructed with a high temperature resistant EPDM or Viton® leak-proof tube and seamless cover with Kevlar® high temperature and high-strength tire cord reinforcement. The construction includes full rubber flanges, high tensile steel reinforcement and hot dip galvanized steel retaining rings. Additionally, they are designed to reduce noise and vibration, have a cycle life in the tens of millions, compensate for misalignments, provide access to piping and equipment and relieve pipe and anchor stresses. This construction, as a standalone expansion joint, represents the most cost-effective arrangement when used in rigid piping systems with main anchors (MA) and numerous guides at specific spacing. Control units can be externally or internally attached and used as limit rods for secondary restraint or as tie rods when the support structure or adjacent equipment have load limitations.

Features

- Versatile hand-built construction

- Standard or custom face-to-face dimensions

- Available in multiple arches or custom offset arrangements and sizes not shown

- Virtually eliminates sediment buildup

- Higher pressure rating than conventional expansion joints

- 350°F continuous service with EPDM / Kevlar®

- 400°F continuous service with Viton® / Kevlar®

- Excellent chemical and abrasion resistance

- Full vacuum rating (30" Hg) in all single arch sizes

- Hot dip galvanized retaining rings standard

- Integral flange design, no gaskets required

- Filled arch design available

- High strength and simple to install

TECHNICAL RESOURCES

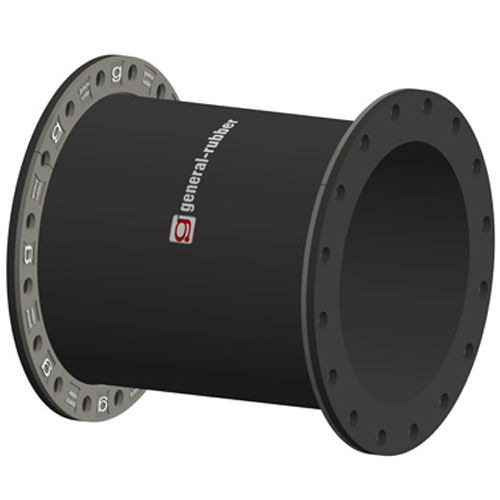

Rubber Flanged Pipe Style 1100

General Rubber's Style 1100 rubber flanged pipes are designed to absorb all-directional movements, reduce noise and vibration, have a cycle life in the tens of millions, compensate for minor misalignments, provide access to piping and equipment and relieve pipe and anchor stresses. Its archless spool type body is constructed with full rubber flanges, a high-grade leak-proof tube, multiple layers of high-strength tire cord, high tensile steel reinforcement, a seamless cover and hot dip galvanized steel retaining rings. This construction, as a standalone expansion joint, represents the most cost-effective arrangement when used in rigid piping systems with main anchors (MA) and numerous guides at specific spacing. Control units can be externally or internally attached and used as limit rods for secondary restraint or as tie rods when the support structure or adjacent equipment have load limitations.

Features

- Versatile hand-built construction

- Standard or custom face-to-face dimensions

- Available in custom offset arrangements and sizes not shown

- 15'' Hg standard design - full vacuum (30'' Hg) available

- 250°F continuous service standard (400°F available)

- Hot dip galvanized retaining rings standard

- Integral flange design, no gaskets required

- High strength and simple to install

TECHNICAL RESOURCES

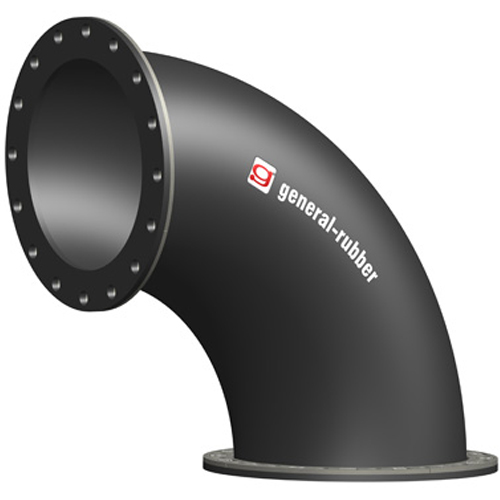

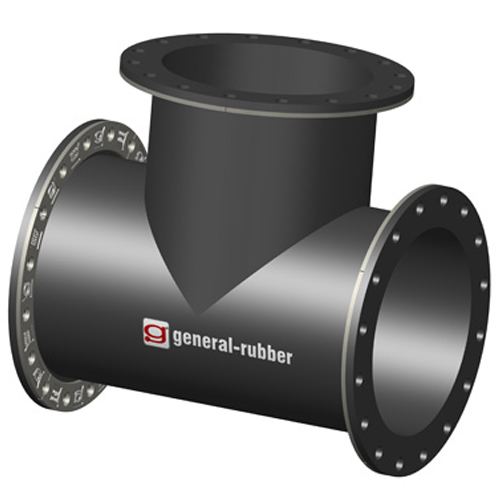

Rubber Flanged Fittings Styles 1100EF, 1100TF, 1100YF

General Rubber's Styles 1100EF, 1100TF and 1100YF rubber flanged fittings are an economical way of combining an elbow, tee, or wye pipe fitting with an expansion joint. Additionally, they are designed to reduce noise and vibration, have a cycle life in the tens of millions, compensate for misalignments, provide access to piping and equipment and relieve pipe and anchor stresses. Its spool type body is constructed with full rubber flanges, a high-grade leak-proof tube, multiple layers of high-strength tire cord, high tensile steel reinforcement, a seamless cover and hot dip galvanized steel retaining rings.

Features

- Versatile hand-built construction

- Standard or custom face-to-face dimensions

- Available in custom offset arrangements and sizes not shown

- Higher pressure rating than conventional expansion joints

- 15'' Hg standard design - full vacuum (30'' Hg) available

- 250°F continuous service standard (400°F available)

- Hot dip galvanized retaining rings standard

- Integral flange design, no gaskets required

- High strength and simple to install

TECHNICAL RESOURCES

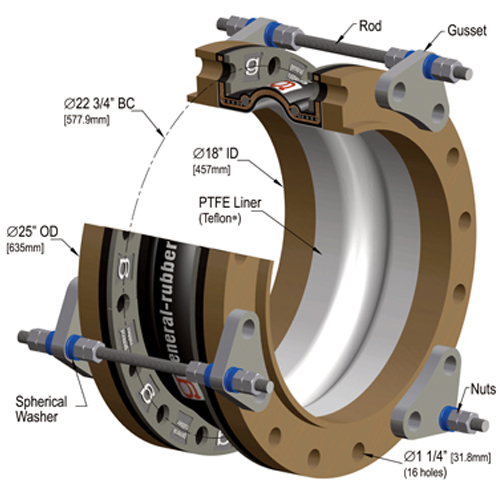

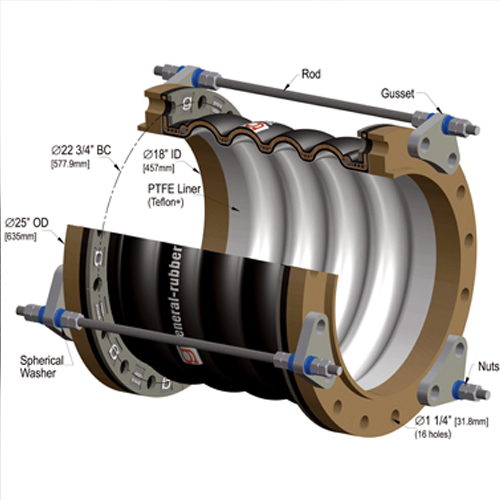

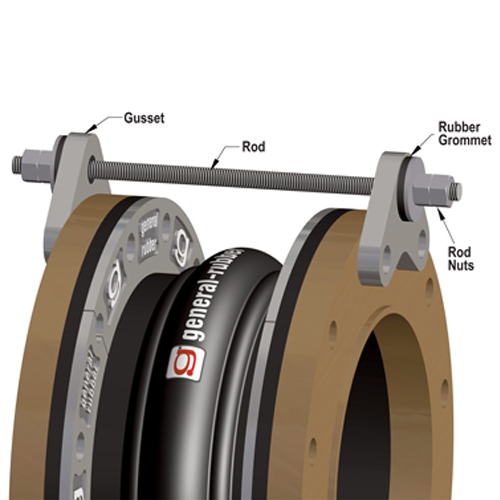

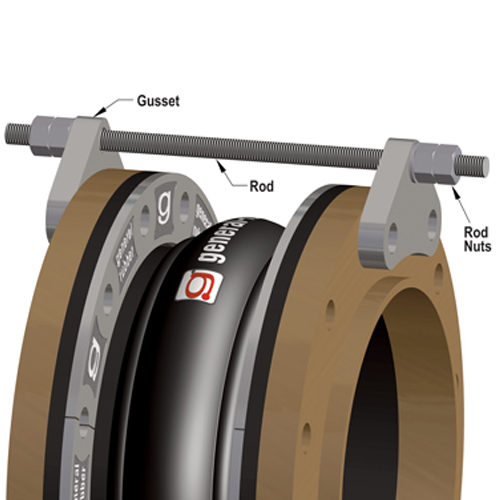

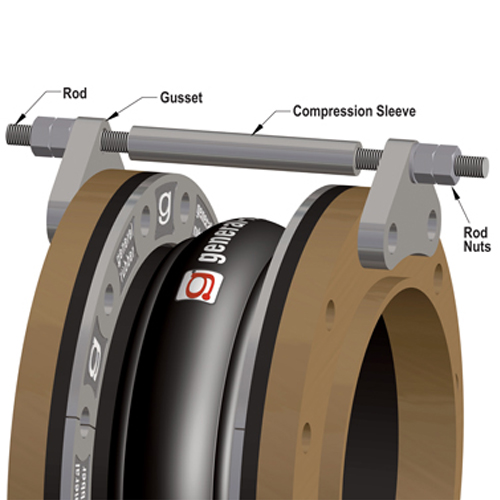

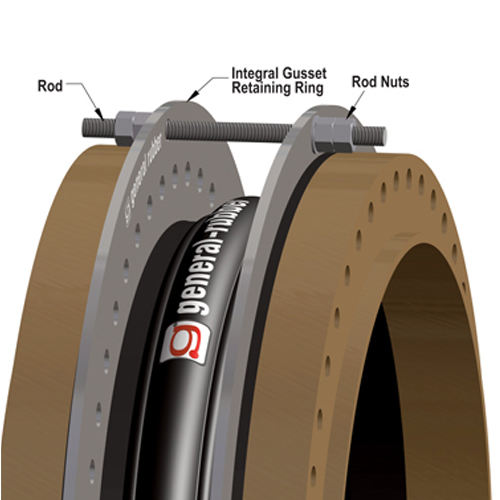

Control Units, Limit Rods and Tie Rods

Control units can be designed as limit rods or tie rods depending on the application. Their designs are based on the calculated thrust force of the rubber expansion joint at the specified pressure and can be attached to the external or internal hardware of the expansion joint. The arrangement can also include a combination of rubber grommets, flat or spherical washers, as well as internal limits for specific applications. The standard gusset plates are high-grade carbon steel with a hot dip galvanized finish, and the standard rods are high tensile steel with a hot dip galvanized finish. Stainless steel control units are also readily available, as are those made of alternative materials including, but not limited to, aluminum, bronze, and Teflon-coated hardware.

Limit Rods are control units designed with a gap to allow the rubber expansion joint's movement range (axial, angular, lateral, and torsional) during normal operation. In the event of main anchor failure, the limits rods will engage and function as a secondary restraint. This will prevent the rubber expansion joints from over-extension or over-compression, by restraining the full pressure thrust loads.

Tie Rods are control units designed to continuously restrain expansion joints axially while also restricting their other movements (angular, lateral and torsional) during normal operation. The tie rods will act as the primary restraint by continuously restraining the full pressure thrust loads.

General Rubber is proud to detail many of these styles on the linked control unit data sheet as well as illustrating them on the expansion joint data sheets.

Features

- Protects expansion joints by restraining pressure thrust forces

- High tensile galvanized steel rods standard, stainless steel and other materials available

- Galvanized gusset plates standard, stainless steel and other materials available

- Rubber grommets isolate vibration and are standard on sizes 1" to 12" diameter

- Internal nuts or compression sleeves to prevent over-compression are available

- Spherical washers prevent binding while minimizing lateral forces

- Double nuts are used to lock limit points and allow for field adjustment

- Custom restraints available including universal, hinge and gimbal arrangements

TECHNICAL RESOURCES

Advanced Restrained Expansion Joints Styles

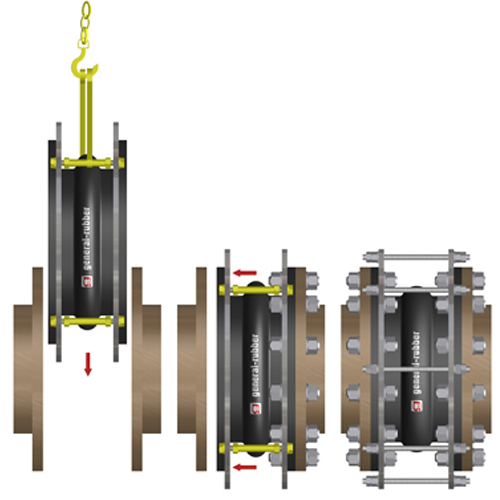

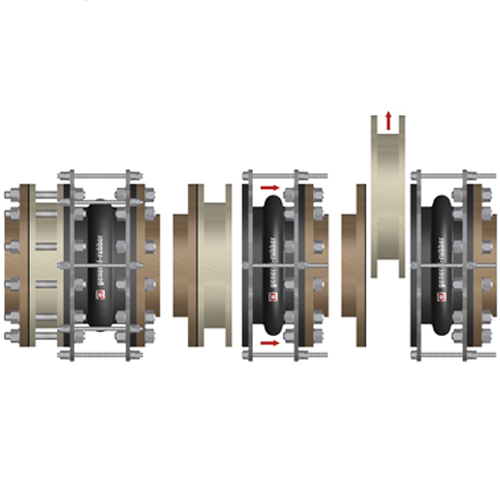

Dismantling Style 5100D

General Rubber's Style 5100D dismantling rubber expansion joint is designed for self-retraction to facilitate access to piping and equipment as well as for unmatched ease of installation and subsequent removal. Additionally, they are designed to absorb large all-directional movements, reduce noise and vibration, have a cycle life in the tens of millions, compensate for misalignments and relieve pipe and anchor stresses. Its spool type body is constructed with full rubber flanges, a high-grade leak-proof tube, multiple layers of high strength tire cord, high tensile steel reinforcement, a seamless cover and hot dip galvanized steel retaining rings. Control units are typically internally attached and used as limit rods for secondary restraint or as tie rods when the support structure or adjacent equipment have load limitations.

Features

- Versatile hand-built construction

- Standard or custom face-to-face dimensions

- Available in multiple arches or custom offset arrangements and sizes not shown

- Virtually eliminates sediment buildup

- Higher pressure rating than conventional expansion joints

- 250°F continuous service standard (400°F available)

- Hot dip galvanized retaining rings standard

- Hot dip galvanized gusset plates and high tensile galvanized steel rods standard

- Integral flange design, no gaskets required

- Filled arch design available

- High strength and simple to install

TECHNICAL RESOURCES

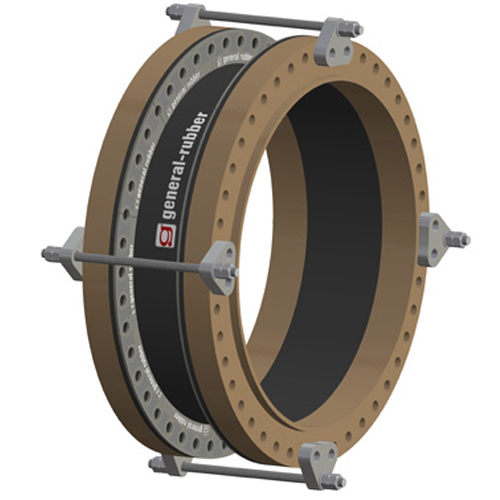

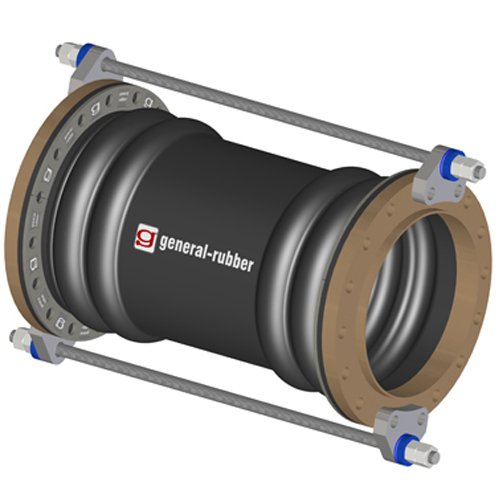

Universal Style 5100U

General Rubber's Style 5100U universal rubber expansion joints feature two resilient arch sections separated by a straight section to facilitate greater lateral movement capability. This single unit arrangement represents an effective solution for absorbing axial thermal movements from adjacent pipe runs. Additionally, they are designed to absorb large all-directional movements, reduce noise and vibration, have a cycle life in the tens of millions, compensate for misalignments, provide access to piping and equipment and relieve pipe and anchor stresses. Its spool type body is constructed with full rubber flanges, a high-grade leak-proof tube, multiple layers of high-strength tire cord, high tensile steel reinforcement, a seamless cover and hot dip galvanized steel retaining rings. Their control units are externally or internally attached and used as limit rods for secondary restraint in a properly anchored piping system or as tie rods when the support structure or adjacent equipment have load limitations.

Features

- Versatile hand-built construction

- Standard or custom face-to-face dimensions

- Available in multiple arches or custom offset arrangements and sizes not shown

- Most economical restrained design

- Higher pressure rating than conventional expansion joints

- 250°F continuous service standard (400°F available)

- Hot dip galvanized retaining rings standard

- Hot dip galvanized gusset plates and high tensile galvanized steel rods standard

- Integral flange design, no gaskets required

- Most economical restrained design

- High strength and simple to install

TECHNICAL RESOURCES

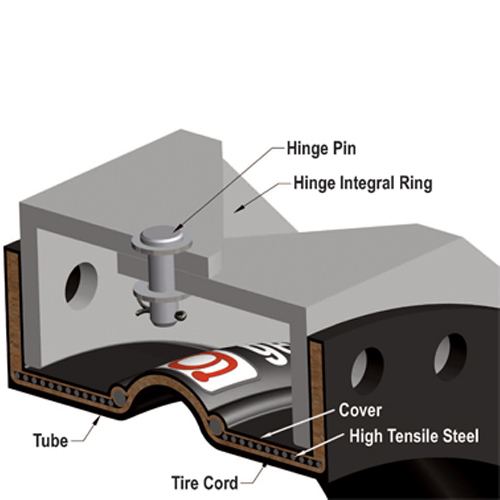

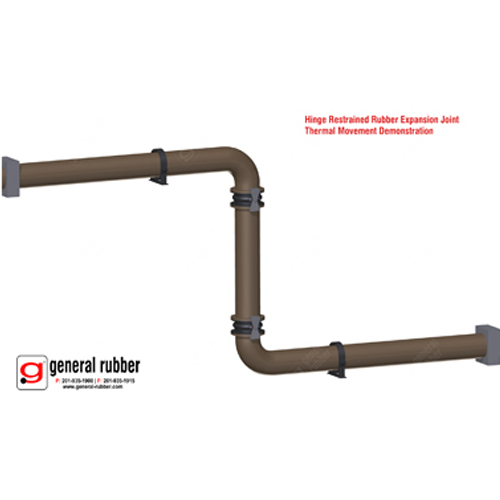

Hinge Style 5100H

General Rubber's Style 5100H hinge rubber expansion joint is designed to facilitate and isolate angular rotation in one plane. The arrangement consists of a pair of hinge plates connected with pins and attached to the external or internal hardware of the expansion joint. The hinge assembly must be designed for the internal pressure thrust forces of the system. They can be used in sets of two or three to absorb large lateral movements in a single plane. This optimally designed arrangement is an effective solution for absorbing large axial thermal movements from an adjacent pipe run. Its spool type body is constructed with full rubber flanges, a high-grade leak proof-tube, multiple layers of high-strength tire cord, high tensile steel reinforcement and a seamless cover. They are commonly used when the support structure or adjacent equipment have load limitations. The economic benefits of this arrangement include a smaller system footprint with far fewer anchors and guides.

Features

- Versatile hand-built construction

- Optional slotted hardware for greater movement capabilities

- Effective restrained design

- Exceptional lateral movement capabilities in sets of two or three

- Available in multiple arch arrangements and sizes not shown

- Higher pressure rating than conventional expansion joints

- 250°F continuous service standard (400°F available)

- Hot dip galvanized retaining rings standard

- Integral flange design, no gaskets required

- Hot dip galvanized hinge plates standard

- High strength and simple to install

TECHNICAL RESOURCES

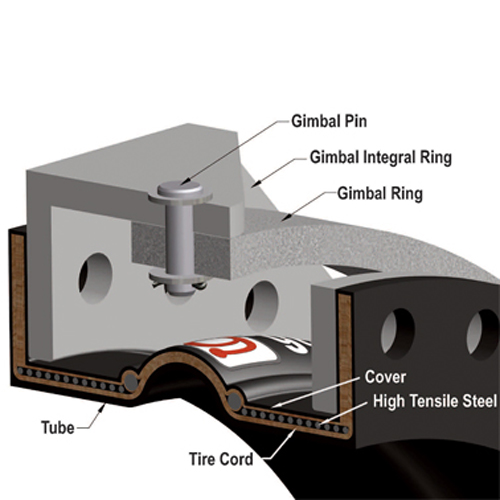

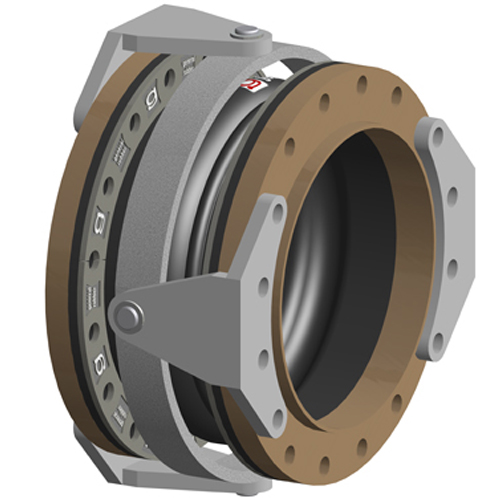

Gimbal Style 5100G

General Rubber's Style 5100G gimbal rubber expansion joint is designed to facilitate and isolate angular rotation in two planes. The arrangement consists of two pairs of hinge plates connected with pins to a common gimbal ring and attached to the external or internal hardware of the expansion joint. The gimbal assembly must be designed for the internal pressure thrust forces of the system. They can be used in sets of two, or sets of two with a single hinge design to absorb large lateral movements in multiple planes. This optimally designed arrangement represents an effective solution for absorbing large axial thermal movements from adjacent pipe runs. Its spool type body is constructed with full rubber flanges, a high-grade leak-proof tube, multiple layers of high-strength tire cord, high tensile steel reinforcement and a seamless cover. They are commonly used when the support structure or adjacent equipment have load limitations. The economic benefits of this arrangement include a smaller system footprint with far fewer anchors and guides.

Features

- Versatile hand-built construction

- Optional slotted hardware for greater movement capabilities

- Effective restrained design

- Exceptional lateral movement capabilities in sets of two or two with a single hinge

- Available in multiple arch arrangements and sizes not shown

- Higher pressure rating than conventional expansion joints

- 250°F continuous service standard (400°F available)

- Hot dip galvanized retaining rings standard

- Integral flange design, no gaskets required

- Hot dip galvanized hinge plates standard

- High strength and simple to install

TECHNICAL RESOURCES

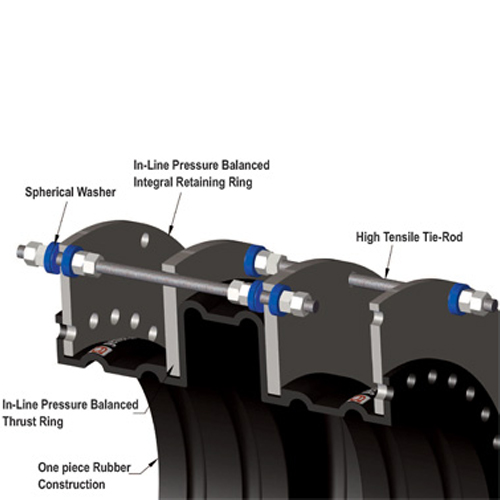

In-Line Pressure Balanced Style 5100P

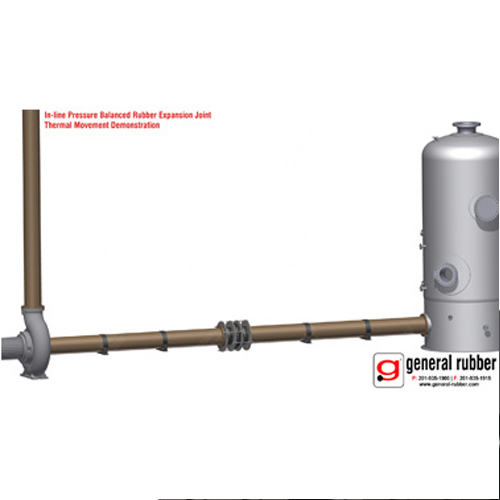

General Rubber's Style 5100P in-line pressure balanced rubber expansion joints are the only effective solution for directly absorbing large axial thermal movements while continuously self-restraining the pressure thrust forces. This arrangement consists of tie devices inter-connecting its main joint sections to its opposing balancing joint section and is commonly used when the support structure or adjacent equipment have load limitations. The body is a one-piece rubber construction with full rubber flanges, a high-grade leak-proof tube, multiple layers of high-strength tire cord, high tensile steel reinforcement, a seamless cover and hot dip galvanized steel retaining rings. Additionally, they are designed to absorb all-directional movement, reduce noise and vibration, have a cycle life in the tens of millions, compensate for misalignments, provide access to piping and equipment and relieve pipe and anchor stresses. The economic benefits of using pressure balanced designs include a smaller system footprint as well as far fewer guides, anchors and supports.

Features

- Versatile hand-built construction

- Excellent all-directional movement capabilities

- 250°F continuous service standard (400°F available)

- Hot dip galvanized retaining rings standard

- Hot dip galvanized gusset plates and high tensile galvanized steel rods standard

- Integral flange design, no gaskets required

- High strength and simple to install

TECHNICAL RESOURCES

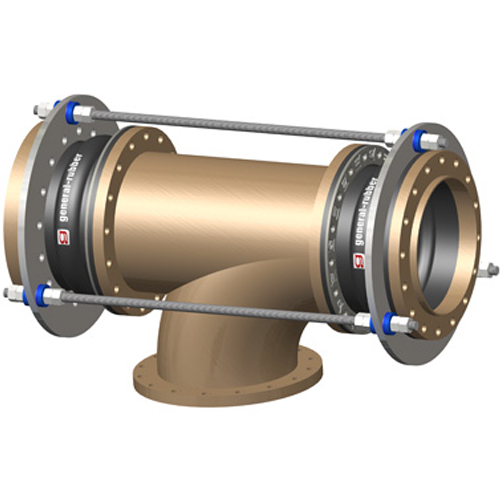

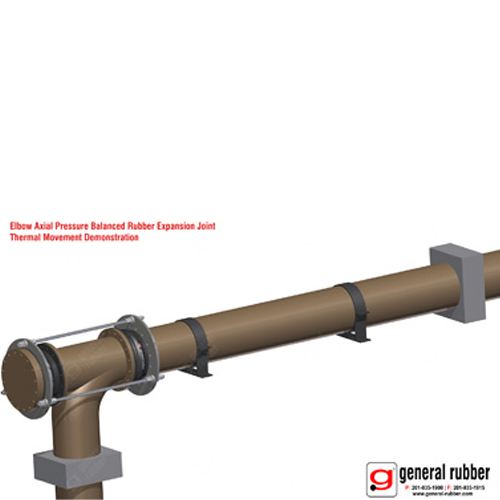

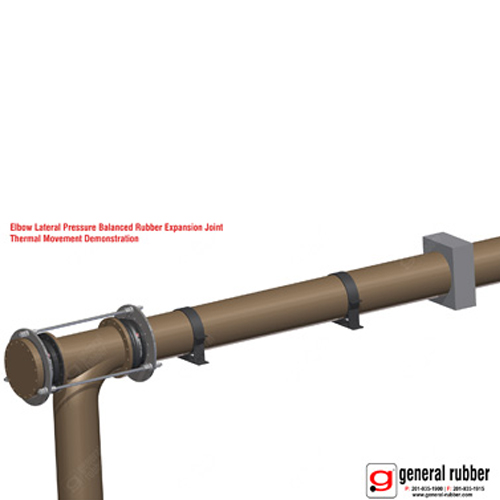

Elbow Pressure Balanced Style 5100E

General Rubber's Style 5100E elbow pressure balanced rubber expansion joint is designed to absorb all-directional movement while continuously self-restraining the pressure thrust forces. This arrangement consists of tie devices inter-connecting its main joint section to its opposing balancing joint section and is commonly used when the support structure or adjacent equipment have load limitations. The pair of spool type bodies are constructed with full rubber flanges, high-grade leak-proof tubes, multiple layers of high-strength tire cord, high tensile steel reinforcements, seamless covers and hot dip galvanized steel retaining rings. Additionally, they are designed to reduce noise and vibration, have a cycle life in the tens of millions, compensate for misalignments, provide access to piping and equipment and relieve pipe and anchor stresses. The economic benefits of using pressure balanced designs include a smaller system footprint as well as far fewer guides, anchors and supports.

Features

- Versatile hand-built construction

- Excellent all-directional movement capabilities

- 250°F continuous service standard (400°F available)

- Hot dip galvanized retaining rings standard

- Hot dip galvanized gusset plates and high tensile galvanized steel rods standard

- Integral flange design, no gaskets required

- High strength and simple to install

TECHNICAL RESOURCES

Ducting Expansion Joints Styles

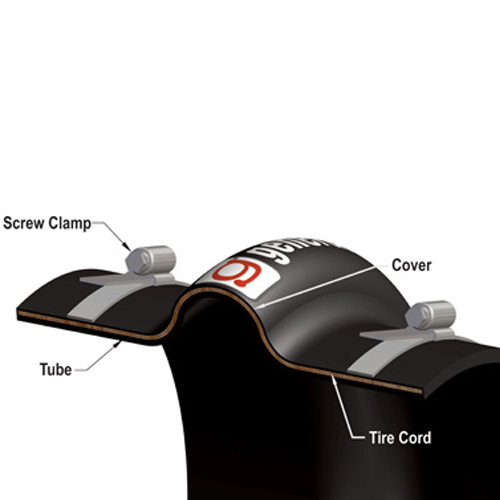

Rubber Slip-On Sleeve Style 8101LW, 8100LW, 1091

General Rubber's Styles 8100LW, 8101LW and 1091 rubber slip-on sleeve type rubber expansion joints are designed with lower spring rates for reduced reaction forces and greater movement capabilities within a compact body. This optimally designed slip-on and lightweight construction represents the most cost-effective arrangement for low pressure applications. Mating flanges and hardware are not required, adding to the cost-effectiveness of this arrangement. The construction includes a high-grade leak-proof tube, a seamless cover, multiple layers of high-strength tire cord and stainless steel screw clamps. Additionally, they are designed to absorb large all-directional movements, reduce noise and vibration, have a cycle life in the tens of millions, compensate for misalignments, provide access to piping and equipment and relieve pipe and anchor stresses.

General Rubber's no-arch Style 8100LW slip-on sleeve is designed with minimal reinforcement for ducting applications operating within ± 5 PSIG.

General Rubber's single arch Style 8101LW slip-on sleeve has exceptional all-directional movement and is designed with minimal reinforcement for ducting applications operating within ± 5 PSIG. Additionally, they are available in multiple arches for increased movements and decreased spring rates as well as custom offsets and reducing arrangements.

General Rubber's fully molded Style 1091 has unique beaded ends to prevent the sleeve from being pulled out from under the clamps, making this design ideal for vibrating bin activators as well as other industrial OEM equipment.

Features

- Versatile hand-built construction

- 250°F continuous service standard (400°F available)

- Available in split-wrap

- Available in multiple arches for greater movements and reduced spring rates

- Available in custom offsets and overall length (OAL) dimensions as well as reducing arrangements

- Economical slip-on design eliminates the need for mating flanges and hardware

- Extremely lightweight and flexible

TECHNICAL RESOURCES

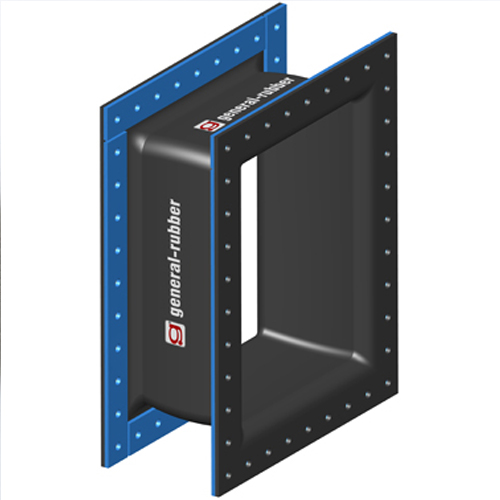

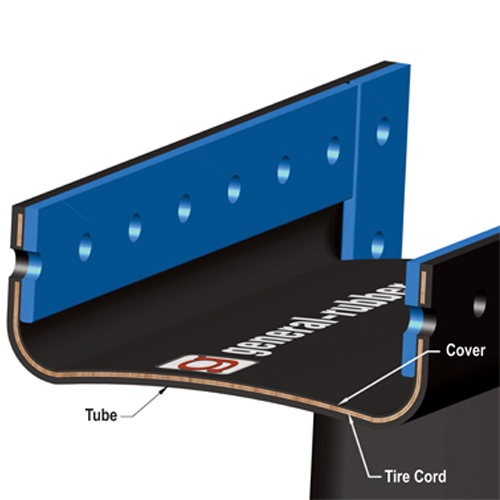

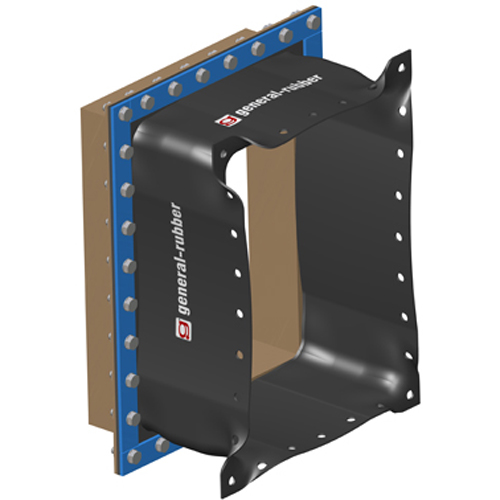

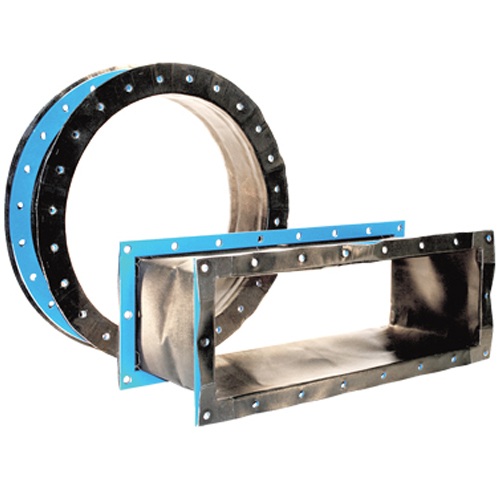

Rubber Flanged Standard Style 1092 and 1097

General Rubber's Styles 1092 and 1097 rubber flanged standard ducting expansion joints are designed with lower spring rates for reduced reaction forces and greater movement capabilities within a compact body. This lightweight construction is optimally designed with external or internal molded flanges and represents the most cost-effective arrangement for low pressure flanged ducting applications. The construction includes a high-grade leak-proof tube, a seamless cover, multiple layers of high-strength tire cord and steel retaining rings. Additionally, they are designed to absorb large all-directional movements, reduce noise and vibration, have a cycle life in the tens of millions, compensate for misalignments, provide access to ducting and equipment and relieve duct and anchor stresses.

General Rubber's Style 1092 offers improved performance capabilities and easier installation based on its U-shaped and performance based molded belt construction. Its fully molded flanges minimize the stresses along the inside edge and are available in standard face-to-face dimensions including 3", 4", 6", 8", 9" and 12".

General Rubber's Style 1097 offers custom face-to-face dimensions based on its flat and versatile molded belt construction.

Features

- 250°F continuous service standard (400°F available)

- ± 3 PSI continuous service

- Extremely lightweight and flexible

- Reducers and offset styles available

- Zero porosity in wet or dry service

- Economical, all-molded construction

- Round and rectangular designs in all styles and sizes

- Exceptional all-directional movement capability

- Absorbs system noise, vibration and shock

- Compensates for minor misalignment and offsets

- Integrally flanged design

- Low stiffness and deflection forces

- Carbon steel, stainless steel, or hot dip galvanized retaining rings available

- No gaskets required

- Excellent chemical and abrasion resistance

- Available with external or internal flanges

TECHNICAL RESOURCES

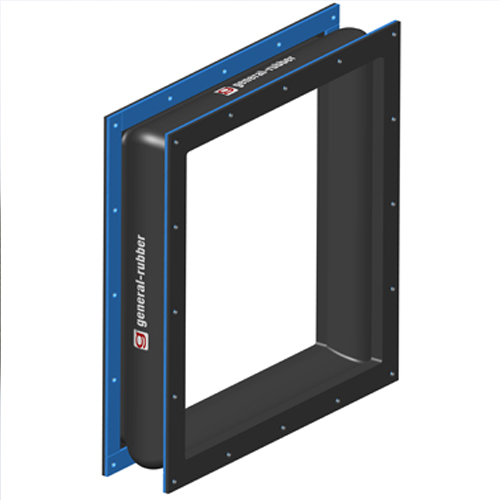

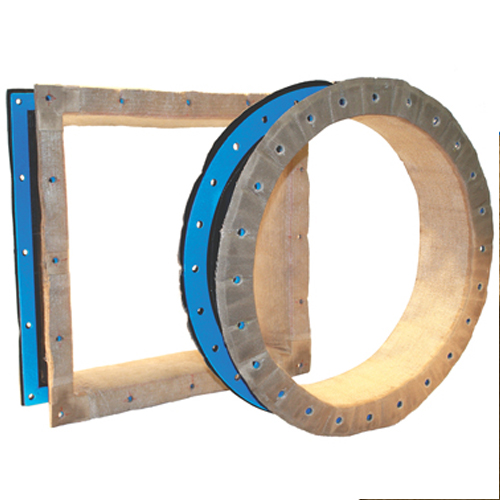

Rubber Flanged Versatile Style 9100 and 9101

General Rubber's Style 9101 completely versatile ducting rubber expansion joint is designed with an integral arch in a hand wrapped construction. This results in lower spring rates for reduced reaction forces and greater movement capabilities within a compact body. This optimally designed lightweight construction represents the most versatile arrangement for even the most demanding ducting applications. The versatile hand-built construction includes full rubber flanges, a high-grade leak-proof tube, a seamless cover, multiple layers of high-strength tire cord and steel retaining rings. Additionally, they are available in multiple arches for increased movements and decreased spring rates as well as custom offsets and reducing arrangements. They are also designed to absorb large all-directional movements, reduce noise and vibration, have a cycle life in the tens of millions, compensate for misalignments, provide access to ducting and equipment and relieve duct and anchor stresses.

Features

- Versatile hand-built construction

- 250°F continuous service standard (400°F available)

- ± 3 PSI continuous service standard (25 PSI available)

- Round or rectangular designs in all sizes

- Available in multiple arches for greater movements and reduced spring rates

- Available in custom offsets and face-to-face dimensions as well as reducing arrangements

- Simple to install, lightweight and high-strength

- Carbon steel, stainless steel, or hot dip galvanized backup rings

- Zero porosity in wet or dry service

- No gaskets required

- Excellent chemical and abrasion resistance

TECHNICAL RESOURCES

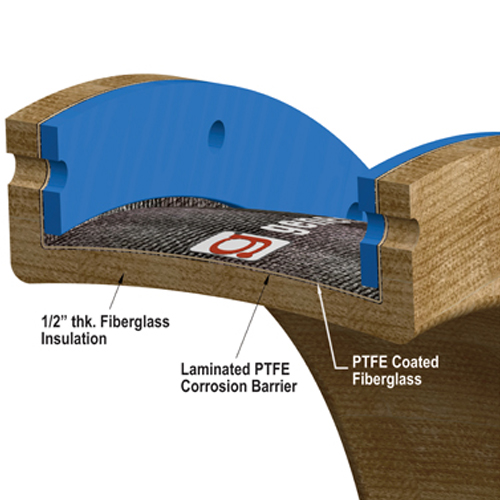

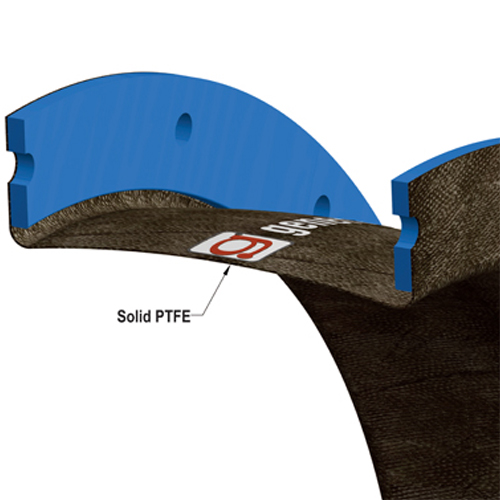

PTFE Single Layer Style 1093 and 1094 and 1095

General Rubber's Styles 1093, 1094 and 1095 PTFE single layer flanged ducting expansion joints are designed with lower spring rates for reduced reaction forces and greater movement capabilities within a compact body. This lightweight construction is optimally designed with external or internal laminated flanges and represents the most cost-effective arrangement for low pressure flanged ducting applications. The construction includes a PTFE fluoropolymer laminated flexible element and steel retaining rings. Additionally, they are designed to absorb large all-directional movements, reduce noise and vibration, compensate for misalignments, provide access to ducting and equipment and relieve duct and anchor stresses.

General Rubber's Style 1093 offers up to 600°F with ± 3 PSI continuous service and zero porosity in wet and dry systems. The flexible element is constructed with PTFE fluoropolymer coated high tensile fiberglass reinforcement and a 9 Mil thick laminated PTFE fluoropolymer corrosion barrier.

General Rubber's Style 1094 offers up to 1,000°F and ± 3 PSI continuous service. The flexible element is constructed with PTFE fluoropolymer coated high tensile fiberglass reinforcement, laminated PTFE fluoropolymer corrosion barrier and a laminated woven or needle mat fiberglass insulation layer.

General Rubber's Style 1095 offers up to 500°F with ± 3 PSI continuous service, zero porosity in wet and dry systems and a cycle life in the millions. The flexible element is constructed of a solid 30 Mil thick PTFE fluoropolymer layer and is available in thicknesses up to 60 Mil; offering the ultimate chemical resistance with no fiberglass component to fatigue.

Features

- Round and rectangular designs in all styles

- Laminated PTFE fluoropolymer corrosion barrier

- Reducers and offset styles available

- Exceptional all-directional movement capability

- Absorbs system noise, vibration and shock

- Compensates for minor misalignment and offset

- Available with external or internal flanges

- Low stiffness and deflection forces

- Simple to install, lightweight and high strength

- Provides easy access to ducting and equipment

- Carbon steel, stainless steel, or hot dip galvanized backup rings available for easy bolting to mating flanges

- Superior chemical resistance

- Heat form and sealed to any size and arrangement

TECHNICAL RESOURCES

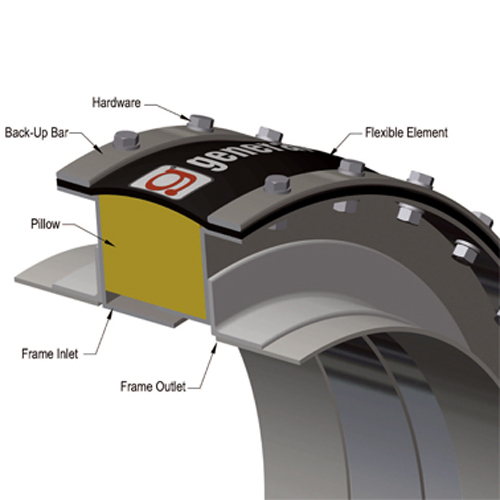

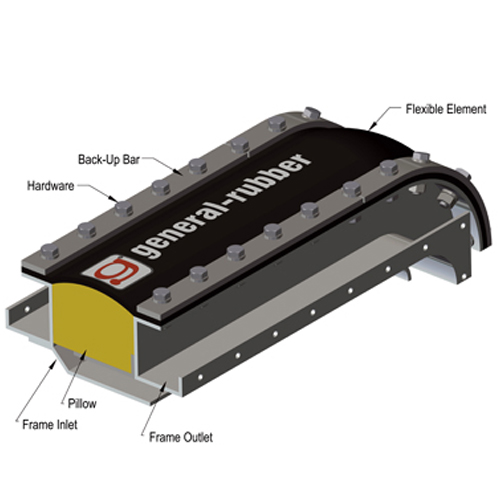

PTFE Composite Style 1096

General Rubber's Style 1096 PTFE composite ducting expansion joint is designed for flue gas continuous service up to 1200°F. This construction is optimally designed with a PTFE fluoropolymer composite flexible element, cavity pillows, steel frames and flow liners as the support structures and applications require. Composite layering includes a heat and abrasion resistant high tensile fiberglass reinforcement (gas side), insulation matting, 9 Mil thick PTFE corrosion barrier (dew point sensitive), insulation matting, high tensile fiberglass reinforcement and an outer layer of PTFE fluoropolymer coated high tensile fiberglass. Additionally, they are designed to absorb large all-directional movements, reduce noise and vibration, compensate for misalignments, provide access to ducting and equipment and relieve duct and anchor stresses.

Features

- Flue gas service up to 1200°F continuous service

- PTFE Fluoropolymer corrosion barrier standard for superior chemical resistance

- Round and rectangular frames available in all sizes

- Available with single or double flow liners

- Easy to field splice or repair by heat sealing

- Exceptional all-directional movement capability

- Absorbs system noise, vibration and shock

- Compensates for minor misalignment and offset

- Field surveys and evaluations available