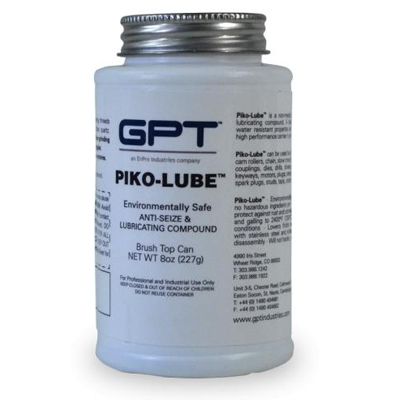

GPT

Piko-Lube™ is a non-metallic, lead free, high-temperature, heavy duty anti-seize and lubricating compound.

Piko-Lube™ non-metallic lubricant contains a blend of extreme-pressure additives, water-resistant properties, and rust and corrosion inhibitors in a high-performance carrier to provide protection up to 2400° F (1315° C). Piko-Lube™ is comprised of molybdenum disulfide, graphite and other solids to ensure maximum performance under the most extreme conditions. It is used in all industries subject to electrical isolation, corrosion, extreme heat and extreme pressure.

FEATURES AND BENEFITS

- Non-conductive lubricant, no heavy metals

- Withstands extreme pressure conditions

- Has no hazardous ingredient per OSHA 29, CFR 1910.1200

- Lowers friction and reduces torque

- Compatible with stainless steel and nickel alloys

- -300° to 2400° F (-184° to 1315° C)

SPECIFICATIONS

- Will not settle, harden or separate under normal conditions.

- Solid Lubricants, Graphite, Molybdenum Disulfide and others 48%.

- Specific Gravity 1.40

- Weight per gallon 11.7 lbs.

- Penetration, D217-60T 100-3000 Strokes 290 - 320

- Oil Separation, 30hr. at 158° < F 1%

- Flash point (475F/246C) Provides protection from -363F/ -184C to 2400F/1315C

- Color Dark Gray

APPLICATIONS

- Appropriate for all industries where electrical isolation, corrosion, extreme heat and extreme pressure can affect sealing integrity.

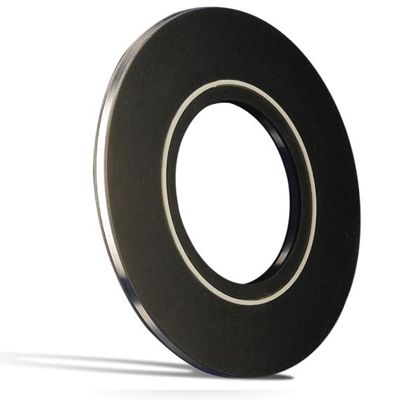

EVOLUTION® Isolation Gasket - The Future of Flange Isolation. Available Now!

EVOLUTION® is a patent pending product that is the first of its kind to be a fully encapsulated isolating gasket. The thinner, 1/8” (3mm) design minimizes the difficulties often encountered while attempting to install thicker isolating gaskets. The total encapsulation allows the gasket to be hydro-tested and kept in the pipeline with virtually no loss in isolation properties.

This innovative gasket is coated using a GPT proprietary material designed specifically for the oil and gas industry that is extremely abrasion and impact resistant. The coating is also chemically resistant to attack from H₂S, steam, CO, CO₂, and other chemicals found in oil and gas pipelines.

EVOLUTION® has passed API 6FB fire testing in multiple sizes and pressure classes and has a considerable increase in operating temperature over GRE products. Furthermore, EVOLUTION® does not have the permeation issues or chemical attack that plagues GRE gaskets.

Under harsh conditions, gaskets made from GRE may be vulnerable to chemical attack, blowout, thermal attack, hydrolysis and emissions —all of which can have serious consequences. EVOLUTION® is different. Its revolutionary materials and design provide industry-leading resistance to leakage and flange corrosion, as well as unprecedented levels of fire safety.

Unlike GRE gaskets, which are prone to delamination, EVOLUTION® has no laminations and as a result can better withstand high-pressure environments.

Rated to 500°F (260°C)*, EVOLUTION® can also operate under high temperatures. Tested comprehensively for safety, the product has API 6FB, 3rd Edition Fire Test recognition.

* When used with Mica sleeves and washers

Patent Pending PCT/US2018/016011

FEATURES AND BENEFITS

316L Stainless Steel Core

- Only three millimeters (1/8 inch) thick

- Thinner profile helps make installation easier and more accurate

Proprietary Coating

- High dielectric strength

- Eliminates expensive exotic cores due to the fully encapsulated coating

- Rated to 500°F (260°C)

*For higher temperature applications, please order MICA sleeves and MICA washers.

Inconel 718 C-Ring

- Fire safe - provides the added security of knowing that the gasket has passed the API 6FB, 3rd Edition Fire Test in multiple sizes/classes

- High pressure - extremely high pressure capability

PTFE ID Seal

- Resistant to typical oil and gas chemicals, in particular H₂S, CO, and CO₂ Impermeable seal and encapsulated carrier eliminates the need to replace gaskets following hydro-testing

- Larger than the pipe bore so that under compression it matches the pipe bore

Handle

- The handle found on the EVOLUTION® allows each gasket to be holiday tested during manufacturing to insure strong isolation performance in the field

- Helps ensure accurate alignment during installation

- Provides traceability and identification for the product

APPLICATIONS

- Fire-safe flange insulation in conjunction with cathodic protection

- Insulation between dissimilar metals to prevent galvanic corrosion

- Wellhead isolation from inter-connected flow lines

- Valve connections

- Christmas Tree connections

- Pump connections

- Compressor connections

- Mating mismatched ring-joint to raised-face flanges (EVOLUTION® will seal in ring-joint, raised-face and flat face/slip-on flanges)

- Eliminate fluid trap corrosion between ring-joint (RTJ) flanges where high concentrations of CO2, H2S and other aggressive hydrocarbon media are present

- Eliminate turbulence and flow-induced erosion between ring-joint (RTJ) flanges.

- To seal between flanges subjected to vibration/cavitation (i.e., compressor stations).

- For slip-on flanges and coated flanges, please contact QUEST.

PTFE spring-energized face seal, or an elastomeric O-ring, seated in an insulating laminate and permanently bonded to a high-strength stainless steel core

The Pikotek® VCS gasket provides exceptional insulating and general sealing performance in aggressive material applications. The VCS gasket is suitable in all services up to and including ANSI 2500# and API 10,000# classes.¹

Due to its unique pressure activated sealing mechanism, the gasket requires far less bolt stress to seal than any other gasket.² The VCS gasket inner diameter is exactly matched to the flange bore to eliminate turbulent flow and flange face erosion/corrosion. The seal elements are replaceable in the reusable gasket retainer.

FEATURES AND BENEFITS

- Extremely high reliability sealing and insulating for all critical services

- Seals and insulates at all pressures up through ANSI 2500# and API 10,000¹#

- Withstands severe service conditions, including large bending moments, vibration, temperature, and pressure cycling¹

- Tackles corrosive environments, including high concentrations of CO2, H2S, produced water, etc.

- Outstanding isolating properties for cathodic protection, galvanic corrosion, and other pipe system isolation needs³

- Pressure activated for reliable sealing and eliminating costly leaks

- Precisely sized to the bore to protect flange faces and prevents turbulent flow at flanged connections to mitigate media-induced corrosion and flow-induced erosion.

- GPT can match the ID of any flange assembly which can greatly mitigate the effects of flow induced corrosion, erosion, and MIC common of other types of gaskets used in piped flange connections

- Mitigates galvanic corrosion in dissimilar metal flanges

- Insulating Kits (sleeves and washers) always include high strength double washers and full-length sleeves for maximum assurance against short circuits

- High strength laminate material resists failure due to excess compression (i.e., over tightening bolts)

- Spring energized PTFE seal provides radial load and encapsulation in the seal groove to eliminate cold flow

- Available to match any flange specification (ANSI, API, BS, DIN, AS, others)

- Can seal mismatched RTJ Flange with Raised Face Flanges

- Re-usable

- Easy installation, make up and removal The rigid construction helps facilitate installation. Low required bolt loads. Less make-up force is required resulting in less flange and bolt stress. Self-aligning and centering No special tools required.

Tandem seal versions available 6” and up and as standard for 24” and up - contact QUEST for other size availability.

Note: Electrical values are based on laboratory conditioned samples in laboratory conditions. Exposure to moisture or elevated temperature will change values- per each test standard (ASTM, etc)

PTFE spring-energized primary sealing element and an E-ring secondary seal, seated in an insulating laminate and permanently bonded to a high-strength metal core, creating a fireproof gasket

The VCFS™* adds fire service capability to the standard Pikotek® VCS design through the use of a secondary sealing element that is capable of maintaining a seal while subject to a 1500°F (815°C) fire. The VCFS fire resistant gasket combines proven sealing performance in aggressive environments with the capability to pass the API 6FB, 3rd Edition fire test³.

Due to its unique pressure activated sealing mechanism, the heat resistant gasket requires far less bolt stress to seal than other gasket types. In addition, the engineered E-ring will serve as a secondary seal during normal operation and the primary sealing element during a fire.

* Note: The “FS” or “Fire Safe” designation denotes only that this gasket has successfully passed the API 6FB fire test. Due to the fact that every fire is unique and many uncontrolled variables are present, no other claims regarding suitability or performance in a fire are made. Each designer, user and/or operator will need to assess their individual situation when deciding to install FS style gaskets. Covered under patents 266755, 7976074, 2271866.

FEATURES AND BENEFITS

- Extremely high reliability sealing and insulating for all critical services

- Withstands severe service conditions, including large bending moments, vibration, temperature and pressure cycling¹

- Tackles corrosive environments, including high concentrations of CO2, H2S, produced water, etc.

- Outstanding insulation properties for cathodic protection ²

- Pressure activated for reliable sealing and eliminating costly leaks

- Precisely sized to the bore to protect flange faces from media-induced corrosion and flow-induced erosion. Prevents turbulent flow at flanged connections

- GPT can match the ID of any flange assembly which can greatly mitigate the effects of flow induced corrosion, erosion, and MIC common of other types of gaskets used in piped flange connections

- Mitigates galvanic corrosion in dissimilar metal flanges

- Insulating Kits (sleeves and washers) always include high strength double washers and full-length sleeves for maximum assurance against short circuits

- High strength laminate material resists failure due to excess compression (i.e., over tightening bolts)

- Spring energized PTFE seal provides radial load and encapsulation in the seal groove to eliminate cold flow

- Available to match any flange specification (ANSI, API, BS, DIN, AS, others)

- Can seal mismatched RTJ Flange with Raised Face Flanges

As per design review. Please contact QUEST for further information.

INSTALLATION

- Easy installation, make up and removal

- Low required bolt loads.

- Less make-up force is required resulting in less flange and bolt stress.

- Self-aligning and centering

- No special tools required.

Tandem seal versions available - contact GPT engineering for size availability

APPLICATIONS

- Fire-safe flange insulation in conjunction with cathodic protection

- Insulation between dissimilar metals to prevent galvanic corrosion

- Wellhead isolation from inter-connected flow lines

- Valve connections

- Christmas Tree connections

- Pump connections

- Compressor connections

- Mating mismatched ring-joint to raised-face flanges (VCFS will seal in ring-joint, raised-face and flat face/slip-on flanges)

- Eliminate fluid trap corrosion between ring-joint (RTJ) flanges where high concentrations of CO2, H2S and other aggressive hydrocarbon media are present

- Eliminate turbulence and flow-induced erosion between ring-joint (RTJ) flanges.

- To seal between flanges subjected to vibration/cavitation (i.e., compressor stations).

SPECIFICATIONS

- Ring type joint (RTJ) flanges from 2”- 36” (50mm - 920mm)

- Raised face flanges from 1”- 36” (25mm - 920mm)

- Compressive Strength: 66,000 psi

- Dielectric Strength: 800 VPM

- Water Absorption: 0.10

- Tensile Strength: LW 40,000 psi / CW 32,000 psi

One isolating and sealing gasket, VCFS Type “F”, 0.260” thick or .308” thick, 316 stainless steel core retainer laminated on both sides with a G-10 fiber glass reinforced laminate containing a precision tapered groove to accommodate the controlled compression of a PTFE spring energized seal. Another groove shall contain a carbon steel backup ring with a proprietary isolating coating and an Inconel® E-ring coated with PTFE. Sealing element placement shall accommodate either flat, raised or RTJ face flanges. The PTFE seal shall be spring and pressure energized. The G-10 retainer shall have an 800 volts/mil dielectric strength and a minimum 66,000 psi compressive strength. The I.D. of the flange isolating gasket shall match the bore of the flange in which it is installed. Product have passed API 6FB fire testing.

Note: Electrical values are based on laboratory conditioned samples in laboratory conditions. Exposure to moisture or elevated temperature will change values.

A concave PTFE Inside Diameter (ID) seal and a PTFE spring-energized face seal, or an elastomeric O-ring, seated in an insulating laminate and permanently bonded to a high-strength core

The VCS-ID (Inside Diameter) Seal introduces an internal, machined PTFE seal at the bore of the existing VCS design platform. The use of a patented interlocking mechanism ensures an extremely tight seal at the bore and resistance to effects from internal pressure or aggressive media. The interlocking mechanism is intentionally designed to be approximately 0.100” larger than the pipe ID.

During installation/loading, the interlocking mechanism will compress to a final state that is slightly larger than the pipe ID. This reduces cavitation in the piping, reduces flange erosion and helps prevent microbiologically induced corrosion (MIC), while not affecting any line pigging operations.

Additionally, the PTFE interlocking mechanism creates a longer effective isolating distance than the standard platform. Traditional VCS gaskets leave the steel core exposed to the media. This increases the likelihood of the formation of an electrically conductive bridge between the flange face and steel core of the gasket, especially if the media contains conductive particles that lead to sediment build-up in the pipeline. Because the thickness of the inner PTFE seal is the same as the gasket thickness, the formation of an electrical bridge caused by conductive sediment build-up between the gasket steel core and the flange face is eliminated. Further, PTFE is not hygroscopic, so it does not have a tendency to absorb water, making it even more attractive as front line defense in electrical isolation. This unique design helps solve problems where hydrotested lines may no longer isolate.

Our patented interlocking mechanism is “dual locking” to provide a secure seal that won’t dislodge during handling, transport or installation. The “dual locking” feature creates a positive lock in both vertical and radial directions.

The interlocking mechanism also eliminates the need for exotic metal gasket core material because it breaks the metal-to-metal path. Obtaining exotic metals can cause long lead times and extra expense that are eliminated with the use of a VCS-ID seal.

Another benefit of the VCS-ID seal is that PTFE doesn’t have an affinity for water absorption, installations where electrical isolation testing is performed shortly after hydro-test are less likely to be corrupted. The VCS-ID does not require any more torque than the standard VCS or VCFS, making installation simple using the same specification charts.

FEATURES AND BENEFITS

- Ideal for applications that would chemically attack GRE

- Installations where electrical isolation testing is performed shortly after hydro-testing

- Creates larger gap between flanges for better resistance to conductive sediment build-up

- Great for use in high Chloride applications that could cause Stress Corrosion Cracking with a stainless steel core

- Eliminates the need for exotic metal cores that match the exotic metal flange material

- Available with G-11 carrier for 392°F / 200°C

- Dual Seal nominal pipe size in 6” and up are standard

- Larger than the pipe bore so that under compression it matches the pipe bore

APPLICATIONS

- Flange insulation in conjunction with cathodic protection

- Insulation between dissimilar metals to prevent galvanic corrosion

- Wellhead isolation from interconnected flow lines

- Valve connections

- Christmas Tree connections

- Pump connections

- Compressor connections

- Chemical applications

- Mating mismatched ring-joint to raised-face flanges (VCS will seal in ring-joint, raised-face and flat face/slip-on flanges)

- Eliminates the fluid trap common to ring type joint (RTJ) flanges where the potential of stress corrosion cracking exists with corrosive medias

- For slip-on flanges, please contact GPT engineering

SPECIFICATIONS

One isolating and sealing gasket, VCS-ID Type “F”, 0.260” thick or .308” thick, 316 stainless steel core retainer laminated on both sides with a G-10 fiber glass reinforced laminate containing a patented, mechanically locking PTFE sealing element. The PTFE element will be concave on the I.D. to induce pressure activation. The PTFE sealing element will be approximately 0.100” larger than the bore. Sealing element placement shall accommodate either flat, raised or RTJ face flanges. The G-10 retainer shall have a 800 volts/mil dielectric strength and a minimum 65,000 psi compressive strength.

Note: Physical, mechanical, and electrical properties are obtained through testing of material samples in laboratory controlled environments. Exposure to moisture or elevated temperature will change values.

A serrated, machined metal core insulating gasket faced with high-temperature THERMa-PUR™, sleeves, washers, metal backing washers and a Garlock 5500 spacer ring.

The VCXT™ high temperature flange insulation sets create a seal and maintain electrical isolation across a wide range of seating stresses and flange classes in elevated temperature service. They can be used in load compromised connections; such as damaged and/or lined flanges and also heavily bolted connections where significant gasket stresses may be generated.

The insulating gaskets and washers have been designed and developed for use in standard pipeline flanges where both cathodic protection and high integrity sealing are required at elevated service temperatures. For non-standard bolted connections please consult your regional GPT sales manager.

FEATURES AND BENEFITS

- Fire safe in compliance with API 607 and API 6FB¹⁺²

- THERMa-PUR™ is suitable for sealing across a wide range of chemicals (pH 0-14) and sweet and sour gaseous and liquid hydrocarbons ³

- The standard 316L core and washer metallurgy are NACE (MRO175) compliant.

- High compression characteristics achieve strong seal over wide range of flange surface finishes

- Exceeds temperature capability of traditional vermiculite or glass/epoxy insulation sets - 770°F⁴

- Better handling/shipping integrity than mica or vermiculite based products

- Sizes available 1/2" - 24" NPS

- Highest temperature rated isolating product available

- Wide range of chemical resistance

APPLICATIONS

- Fire-safe flange insulation in conjunction with cathodic protection

- Insulation between dissimilar metals to prevent galvanic corrosion

- Wellhead isolation from inter-connected flow lines

- Valve connections

- Christmas Tree connections

- Pump connections

- Compressor connections

- Mating mismatched ring-joint to raised-face flanges (VCFS will seal in ring-joint, raised-face and flat face/slip-on flanges)

- Prevents fluid trap corrosion between ring-joint (RTJ) flanges where high concentrations of CO2, H2S and other aggressive hydrocarbon media are present

- Eliminate turbulence and flow-induced erosion between ring-joint (RTJ) flanges.

- A better option for steam applications than GRE

SPECIFICATIONS

- Operational pressure range: Full vacuum to ASME B16.5 1500# API

- Maximum Operating Temperature Range: -328°F to 770°F (-200°C to 410°C)

Note: Electrical values are based on laboratory conditioned samples in laboratory conditions. Exposure to moisture or elevated temperature will change values.

TYPICAL PHYSICAL PROPERTIES

Insulating Gasket and Washers

- Core Thickness Facing Thickness: 3.2mm/.125” (316SS Core); 1mm/.040” (x2) (Facing)

- Factor (m) ASME Minimum: 4.00

- Seating Stress (y): 3625 psi (25 MPa)

- Dielectric Strength (ASTM D149a): 3.937 kV/mm

Mica Insulating Sleeves

- Maximum Temperature Dielectric Strength: +500˚C 20.0 kV/mm

Mica Washers

- Stainless Steel: 0.125” thick

Other washer material can be provided to suit the application

Flange Isolation Kits consisting of an isolating gasket and isolating sleeves and washers

LineBacker® sealing gaskets use a rectangular sealing element, referred to as a "quad" ring, in combination with a unique groove design to effectively seal and isolate flanges of all types. With the unique quad ring design, elastic memory is provided for elastomers not normally associated with this characteristic. Materials such as PTFE may therefore be used as sealing elements, dramatically increasing the ability to match gasket materials to service conditions. This greater variety of materials also provides excellent temperature and chemical range compatibility. LineBacker® sealing gaskets are self-energizing resulting in a positive seal without excessive bolt loads - as are often required with flat gaskets.

FEATURES AND BENEFITS

- Guards against blowouts¹

- Usable with virtually any type of flange

- Matches gasket materials to service conditions

- Lowest possible clamp and compressive load

SPECIFICATIONS

- All standard ANSI and API flange sizes from 1/2" and above

- Custom odd sizes and shapes

- AWWA flange sizes from 1/2" and above

The LineBacker® gasket is constructed from G10 glass-reinforced epoxy (GRE). The LineBacker® contains a rectangular sealing element referred to as a “quad-ring.” The quad-ring is used in combination with a unique, engineered groove design and together they provide an effective sealing element that also requires less bolt load than a typical flat gasket. The sleeves and washers offered with the LineBacker® gasket are completely temperature dependent. Most commonly used are Mylar and G10 sleeves accompanied by G10 and zinc plated steel washers. Sleeve will be designed to mate with separate isolating washers and will be of a length such that the sleeve extends into one and one-half washer thicknesses on each side of the flange.

PRESSURE RATINGS

All ANSI rated flanges to 600#/2,225 psi respectively. Maximum hydrotest pressure is 2480 psi and 302Fp>

APPLICATIONS

The LineBacker™ is an excellent choice for isolating distribution lines and transport lines for gas, oil and water. The screened version is the best available product for filtering welding slag, rocks, nuts, bolts and other particulates from traveling downstream and damaging valves, pumps, compressors, etc. Because the LineBacker™ has very good resistance to creep relaxation², it performs well in heat exchangers, applications with high vibration or excessive thermal cycling.

OPTIONS

Gasket Types

All kits are correctly sized for the application and conveniently packaged to minimize loss of component parts during installation.

Type E Gasket (Full Face) The gasket retainer extends out to the O.D. of the flange. Holes are cut at the bolt circle to accommodate threaded studs and sleeves.

Type F Gasket(Ring Type) The gasket retainer extends out to the I.D. of the bolt circle. The threaded studs and sleeves center the gasket in the flange.

Single Washer Set flange isolation kits include the following items for each threaded stud:

- One - 1/8" thick steel washer

- One - Isolating Washer

- One - Isolating Sleeve

Application Considerations

In buried applications, single washer configurations may be used to allow the Cathodic Protection (CP) current to reach the nuts and bolts. If desired, nuts on the opposite side of the cathodically protected flange may be included as part of the protected system.

Double Washer Set

Double washer set flange isolation kits include the following components for each bolt:

- Two - 1/8" thick steel washers

- Two - Isolating washers

- One - Full length isolating sleeve

Application Considerations

Double washer configurations may be used for added protection against the possibility of "shorting out" the nuts and bolts. In addition, double washer sets electrically isolate the nuts and bolts from both flanges.

Acetal One-Piece Sleeve and Washer Sets

One-piece sleeves eliminate the possibility of error by installers. One-piece sleeve and washer set flange isolation kits include the following items for each bolt:

- Two - 1/8" thick steel washers

- One-One-piece isolating sleeve

Application Considerations

Easier to install, one-piece sleeves also allow the inspector a visual indication of sleeve usage. Due to the relatively low compressive strength of this material, its use is not recommended for high pressure or large diameter flanges that require high torque loads.