Graphite Products

Description:

Graphite is one of the most reliable sealing materials. It offers excellent resistance to acids,

alkaline solutions and organic composites.

It has excellent temperature range of –400°F to 5400°F,

in reducing or neutral service without contact with Oxygen.

For oxidant service the upper limit is 840°F.

- High temperature

- High conformability to flange irregularity

- Wide range of operating temperatures and pressures

- Excellent chemical resistance

2660/1660 Homogeneous Flexible Graphite Sheet

Description and Applications

Style 2660/1660 flexible graphite sheet has pressure-temperature sealability capabilities that are far superior to all compressed fiber reinforced sheet materials. It is resistant to chemical attack by virtually all organic and inorganic fluids with the exception of concentrated, highly oxidizing acids. Gaskets cut from Style 2660/1660 flexible graphite sheet seal with low to moderate bolt loads and because of very low creep relaxation, re-torquing is rarely required. Flexible graphite conforms to irregular flange sealing surfaces and readily flows into flange irregularities enabling it to seal both smooth and coarse surface finishes.

Construction

Style 2660/1660 flexible graphite sheet is made from exfoliated graphite flake which is compressed into foil by a carefully controlled calendering process. In this process, the expanded flake particles are mechanically locked together without the use of fibers, binders or other additives. Sheets of graphite foil are then adhesive bonded and laminated to the required thickness.

Service Limits

| Temperature ºF (ºC) | Continuous Service: -328 (-200) |

|---|---|

| Maximum Service: In air: 842 (450) | |

| In steam: 1202 (650) | |

| In reducing or inert media: 5432 (3000) | |

| Availability | 39 x 39 in |

| 60 x 60 in | |

| Thickness | 1/64"*, 3/32"*, 1/32", 3/16"*, 1/16", 1/8", 1/4" |

| *thickness available upon request |

| Typical Physical Properties: | |

|---|---|

| Density | 62.4 lb/ft3 |

| Compressibility - Tested under 5000 psi | 45% |

| Recovery - Tested under 5000 psi | 20% |

| Tensile Strength Across Grain | 650 psi |

| Creep Relaxation | 5% |

| Compressive Strength | 20,000 psi |

| Carbon Content | 98% minimum |

| Total sulfur | ≤ 750 ppm maximum |

| Leachable Chlorides | < 30 ppm maximum |

Datasheet 2660/1660

| Availability | Size: 39 x 39 in

60 x 60 in |

|---|---|

| Thickness: 1/64”, 1/32”, 1/16”, 3/16, 3/32”, 1/8”, 1/4" | |

| Temperature | Continuous Service: -392ºF (-200ºC) |

| Maximum Service: In air: 842ºF (450ºC) | |

| In steam: 1202ºF (650ºC) | |

| In reducing or inert media: 5432ºF (3000ºC) |

| Typical Physical Properties: | |

|---|---|

| Density | 62.4 lb/ft3 |

| Compressibility - Tested under 5000 psi | 45% |

| Recovery - Tested under 5000 psi | 20% |

| Tensile Strength Across Grain | 650 psi |

| Creep Relaxation | 5% |

| Compressive Strength | 20,000 psi |

| Carbon Content | 98% minimum |

| Total sulfur | ≤ 750 ppm maximum |

| Leachable Chlorides | < 30 ppm maximum |

2661/1661 Flexible Graphite Sheet (316SS Foil Insert)

Description and Applications

Style 2661/1661 flexible graphite sheet has pressure-temperature sealability capabilities that are far superior to all compressed fiber reinforced sheet materials. It is resistant to chemical attack by virtually all organic and inorganic fluids with the exception of concentrated, highly oxidizing acids. Gaskets cut from Style 2661/1661 flexible graphite sheet seal with low to moderate bolt loads and because of very low creep relaxation, re-torquing is rarely required. Flexible graphite conforms to irregular flange sealing surfaces and readily flows into flange irregularities enabling it to seal both smooth and coarse surface finishes.

Construction

Style 2661/1661 is a flexible graphite sheet reinforced with a 316SS foil, .002” thick. The flexible graphite sheet is made from exfoliated graphite flake which is compressed into foil by a carefully controlled calendaring process. In this process, the expanded flake particles are mechanically locked together without the use of fibers, binders or other additives. Sheets of graphite foil are then adhesive bonded and laminated to the required thickness with the 316SS foil core in the center.

Service Limits

| Temperature ºF (ºC) | Continuous Service: -328 (-200) |

|---|---|

| Maximum Service: In air: 842 (450) | |

| In steam: 1202 (650) | |

| In reducing or inert media: 5432 (3000) | |

| Availability | 39 x 39 in |

| 60 x 60 in | |

| Thickness | 1/64"*, 3/32"*, 1/32", 3/16"*, 1/16", 1/8", 1/4" |

| *thickness available upon request |

| Typical Physical Properties: | |

|---|---|

| Density | 62.4 lb/ft3 |

| Compressibility - Tested under 5000 psi | 35% |

| Recovery - Tested under 5000 psi | 18% |

| Tensile Strength Across Grain | 5000 psi |

| Creep Relaxation | 12% |

| Compressive Strength | 24,000 psi |

| Carbon Content | 98% minimum |

| Total sulfur | ≤ 750 ppm maximum |

| Leachable Chlorides | < 30 ppm maximum |

Datasheet 2661/1661

| Availability | Size: 39 x 39 in

60 x 60 in |

|---|---|

| Thickness: 1/64”, 1/32”, 1/16”, 3/16, 3/32”, 1/8”, 1/4" | |

| Temperature | Continuous Service: -328ºF (-200ºC) |

| Maximum Service: In air: 842ºF (450ºC) | |

| In steam: 1202ºF (650ºC) | |

| In reducing or inert media: 5432ºF (3000ºC) |

| Typical Physical Properties: | |

|---|---|

| Density | 62.4 lb/ft3 |

| Compressibility - Tested under 5000 psi | 35% |

| Recovery - Tested under 5000 psi | 18% |

| Tensile Strength Across Grain | 5000 psi |

| Creep Relaxation | 12% |

| Compressive Strength | 24,000 psi |

| Carbon Content | 98% minimum |

| Total sulfur | ≤ 750 ppm maximum |

| Leachable Chlorides | < 30 ppm maximum |

2663/1663 Flexible Graphite Sheet (316SS Tanged Core)

Description and Applications

Style 2663/1663 flexible graphite sheet has pressure-temperature sealability capabilities that are far superior to all compressed fiber reinforced sheet materials. It is resistant to chemical attack by virtually all organic and inorganic fluids with the exception of concentrated, highly oxidizing acids. Gaskets cut from Style 2663/1663 flexible graphite sheet seal with low to moderate bolt loads and because of very low creep relaxation, re-torquing is rarely required. Flexible graphite conforms to irregular flange sealing surfaces and readily flows into flange irregularities enabling it to seal both smooth and coarse surface finishes.

Construction

Style 2663/1663 is a flexible graphite sheet reinforced with a 316SS tanged core, .005” thick. The flexible graphite sheet is made from exfoliated graphite flake which is compressed into foil by a carefully controlled calendaring process. In this process, the expanded flake particles are mechanically locked together without the use of fibers, binders or other additives. Sheets of graphite foil are then adhesive bonded and laminated to the required thickness with the 316SS tanged core in the center.

Service Limits

| Temperature ºF (ºC) | Continuous Service: -328 (-200) |

|---|---|

| Maximum Service: In air: 842 (450) | |

| In steam: 1202 (650) | |

| In reducing or inert media: 5432 (3000) | |

| Availability | 39 x 39 in |

| 60 x 60 in | |

| Thickness | 1/64"*, 3/32"*, 1/32", 3/16"*, 1/16", 1/8", 1/4" |

| *thickness available upon request |

| Typical Physical Properties: | |

|---|---|

| Density | 62.4 lb/ft3 |

| Compressibility - Tested under 5000 psi | 35% |

| Recovery - Tested under 5000 psi | 18% |

| Tensile Strength Across Grain | 5000 psi |

| Creep Relaxation | 10% |

| Compressive Strength | 24,000 psi |

| Carbon Content | 98% minimum |

| Total sulfur | ≤ 750 ppm maximum |

| Leachable Chlorides | < 30 ppm maximum |

Datasheet 2663/1663

| Availability | Size: 39 x 39 in

60 x 60 in |

|---|---|

| Thickness: 1/64”, 1/32”, 1/16”, 3/16, 3/32”, 1/8”, 1/4" | |

| Temperature | Continuous Service: -328ºF (-200ºC) |

| Maximum Service: In air: 842ºF (450ºC) | |

| In steam: 1202ºF (650ºC) | |

| In reducing or inert media: 5432ºF (3000ºC) |

| Typical Physical Properties: | |

|---|---|

| Density | 62.4 lb/ft3 |

| Compressibility - Tested under 5000 psi | 35% |

| Recovery - Tested under 5000 psi | 18% |

| Tensile Strength Across Grain | 5000 psi |

| Creep Relaxation | 10% |

| Compressive Strength | 24,000 psi |

| Carbon Content | 98% minimum |

| Total sulfur | ≤ 750 ppm maximum |

| Leachable Chlorides | < 30 ppm maximum |

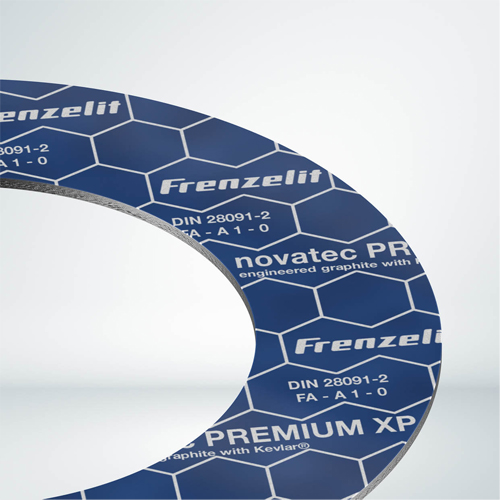

novatec® PREMIUM XP The next generation of fiber-reinforced graphite gaskets

Description

novatec® PREMIUM XP is the third generation of fiberreinforced graphite gasket developed by Frenzelit. novatec® PREMIUM XP is superior to conventional fiber gaskets due to its extremely high graphite content, which makes it extraordinarily resistant with excellent residual stress.

Sophisticated process technology is used in the production of ® PREMIUM XP. In addition, the graphite morphology has been optimized as the structure of the graphite also greatly influences the sealing performance. This targeted adjustment paired with the formula’s high density enables novatec® PREMIUM XP to achieve sealing category L0,01 in typical applications and thus meet the strict criteria of TA Luft and VDI 2290. DIN EN 1591-1 compliant gasket system designs are therefore no problem with novatec® PREMIUM XP.

novatec® PREMIUM XP closes the gap between conventional fiber and graphite gaskets and offers a true alternative for applications with demanding media and temperatures up to approx. 250 °C. The material is highly compressed and has above-average residual stress, so no metal reinforcement is needed. This lack of a metal insert has a positive effect on the chemical resistance.

novatec® PREMIUM XP gaskets can be manufactured with ease – even directly on site – using all standard methods.

Another feature of novatec® PREMIUM XP is its royal blue anti-stick coating, which is effective throughout the entire temperature range with long-term stability.

Technical Data Sheet

| Approvals and tests | BAM, BS 7531 Grade X, DVGW, EG 1935/2004, GL, SVGW, TA Luft |

|---|---|

| Color | royal blue |

| Printing | Platinum grey honeycomb brand |

| Treatment | Anti-stick coating |

| Typical Physical Properties: | |||

|---|---|---|---|

| Thickness | 2,00 mm | ||

| Density | DIN 28090-2 | 1,74 g/cm3 | |

| Residual stress | 175 °C | DIN 52913 | 37 N/mm2 |

| 300 °C | 30 N/mm2 | ||

| Compressibility | ASTM F 36 J | 6% | |

| Recovery | 60% | ||

| Cold compressibility | DIN 28090-2 | 6% | |

| Cold recovery | 3% | ||

| Hot creep | 8% | ||

| Hot recovery | 2% | ||

| Specific leakage rate | DIN 3535-6 | 0,05 mg/m/s | |

| Tensile strength longitudinal | DIN 52910 | 20 N/mm2 | |

| Tensile strength transverse | 18% | ||

| Fluid resistance ASTM F 146 | |||

| Weight change | 5 h / 150 °C | 8% | |

| Thickness change | 5% | ||

| Weight change | 5 h / 23 °C | 5% | |

| Thickness change | 5% | ||

| Leachable chloride content | PV01605 | ≤50 ppm | |

| Product data (tolerances acc. to DIN 28091-1) | |

|---|---|

| Dimensions | [mm] 1500 x 2000 |

| Thicknesses | [mm] 1,0 / 1,5 / 2,0 / 3,0 |

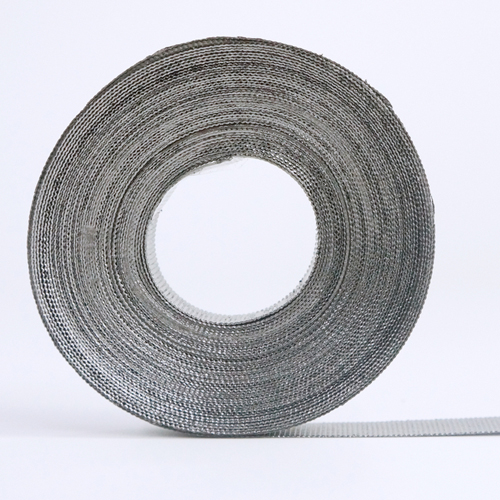

2550/ 2551 Flexible Graphite Tape

Description and Applications

Styles 2550 and 2551 crinkled flexible graphite tape are made from high purity graphite with no fibers, binders or other additives. Style 2550 crinkled tape is typically used as a stuffing box packing for pumps and valves. Style 2551 is the same as 2550 except that it is furnished with a self-adhesive backing strip to facilitate installation as a form-in-place gasket, thread sealant, or for facing jacketed and other difficult-to-seal gaskets.

Styles 2550 and 2551 flexible graphite covers a broad range of sealing applications. It handles most chemicals in the 0 - 14 pH range at cryogenic and elevated temperatures, and from vacuum to extreme pressures. It is used extensively in the chemical, automotive and pump and valve industries.

Service Limits

| Temperature ºF (ºC) | Maximum -392 (-200) | |

|---|---|---|

| Maximum | In air: 842 (450) | |

| In steam: 1202 (650) | ||

| In reducing or inert media: 5432 (3000) | ||

| Pressure psi (bar) | Static 1987 (137) | |

| pH | 0 - 14 | |

| Thickness(in) | .015 | |

| Width (in) | 1/4", 3/8", 1/2", 3/4", 1", 1-1/4", 1-1/8", 1-3/4", 2" | |

| Spool Length (ft) | 1/4" thru 1-1/8"...50' | |

Datasheet 2550/2551

| Temperature ºF (ºC) | Maximum -392 (-200) | |

|---|---|---|

| Maximum | In air: 842 (450) | |

| In steam: 1202 (650) | ||

| In reducing or inert media: 5432 (3000) | ||

| Pressure psi (bar) | Static 1987 (137) | |

| pH | 0 - 14 | |

| Thickness(in) | .015 | |

| Width (in) | 1/4", 3/8", 1/2", 3/4", 1", 1-1/4", 1-1/8", 1-3/4", 2" | |

| Spool Length (ft) | 1/4" thru 1-1/8"...50' | |

| Standard Packaging | |

|---|---|

| Tape Thickness | .015 |

| Tape Width | 1/4”, 3/8”, 1/2”, 3/4”, 1”, 1-1/4”, 1-1/8”, 1-3/4”, 2” |

| Spool Length | 1/4” thru 1-1/8”...50’ |

| 1/4” thru 1-1/8”...100’ | |