Compressed Fiber Sheet

Description:

Compressed Fiber gaskets are produced from a combination of fibers and bonded with elastomers to

provide flexibility and elasticity.

High temperatures and pressure and its low cost compared with

performance makes it the product of choice to fabricate industrial gaskets.

- High Resistance to seating stress

- Low creep relaxation

- Wide range of operating temperatures and pressures

- Resistance to an extensive range of chemicals Aramid Fiber

Premium

Aramid fibers with an NBR binder

The BLUE-GARD® Style 3000 compressed fiber gasketing is made with aramid fibers with an NBR binder. This gasket provides improved torque retention and drastically lowers emissions levels. It also cuts operational costs by reducing waste and energy consumption.

FEATURES AND BENEFITS

- Excellent sealability

- Improved torque retention

- Drastically lowered emissions levels

- Cuts operational costs through reduced waste, maintenance, stocked inventory, fluid loss, and energy consumption

- Available in sheet or cut gasket form

SPECIFICATIONS

- Unique blend of aramid fibers, fillers and an NBR rubber binder

- Blue color

- Min. Temperature: -100°F / -73°C

- Max. Temperature: 700°F / 371°C

- Continuous Max: 400°F / 205°C

- Max Pressure: 1000 PSI / 70 bar

- Maximum PxT 1/16: 350,000°F x PSIG / 12,000 bar x °C

- Maximum PxT 1/8: 250,000°F x PSIG / 8,600 bar x °C

APPLICATIONS

- Utility Services

- Water

- Aliphatic hydrocarbons

- Oils

- Gasoline

Aramid Fibers with an SBR Binder

The BLUE-GARD® Style 3200 gasket provides excellent sealability and improved torque retention. Available in a variety of specifications, it meets MIL-DTL-24696C Type 2 Specifications and can be used in water, saturated steam, and inert gas applications.

FEATURES AND BENEFITS

- Excellent sealability

- Improved torque retention

- Drastically lowered emissions levels

- Cuts operational costs through reduced waste, maintenance, stocked inventory, fluid loss, and energy consumption

SPECIFICATIONS

- Unique blend of aramid fibers, fillers and an SBR rubber binder

- Off-white color

- Full face or ring

- Meets ABS (American Bureau of Shipping) and MIL-DTL-24696C6 Specifications

- Min. Temperature: -100°F -73°C

- Max. Temperature: 700°F 371°C

- Continuous Max: 400°F 205°C

- Max Pressure: 1200 PSI 83 bar

- Maximum PxT 1/16: 350,000 (°F x PSIG) 12,000 bar x °C

- Maximum PxT 1/8: 250,000 (°F x PSIG) 8,600 bar x °C

APPLICATIONS

- Water

- Saturated steam*

- Inert gases

*This style is not the preferred choice for steam services, but is successful when adequately compressed. Minimum recommended assembly stress = 4,800 psi. Preferred assembly stress = 6,000-10,000 psi. Gasket thickness of 1/16” strongly preferred. Retorque the bolts/studs prior to pressuring the assembly. For saturated steam above 150 psig or superheated steam, consult Quest Gasket .

ADDITIONAL INFORMATION

Contact QUEST GASKET

Aramid Fibers with a Neoprene Binder

The BLUE-GARD® Style 3300 provides excellent sealability, which drastically lowers emissions levels and provides cost savings. This style can be used in many applications, including refrigerants, oils, and fuels.

FEATURES AND BENEFITS

- Excellent sealability

- Improved torque retention

- Drastically lowered emissions levels

- Cost savings through reduced waste, maintenance, stocked inventory, fluid loss, and energy consumption

SPECIFICATIONS

- Unique blend of aramid fibers, fillers and an NBR rubber binder, Aramid fibers with a neoprene binder Blue color

- Min. Temperature: -100°F -73°C

- Max. Temperature: 700°F / 371°C

- Continuous Max: 400°F / 205°C

- Max Pressure: 1200 PSI / 83 bar

- Maximum PxT 1/16: 350,000 (°F x PSIG) 12,000 bar x °C

- Maximum PxT 1/8: 250,000 (°F x PSIG) 8,600 bar x °C

APPLICATIONS

- Water

- Saturated steam*

- Refrigerants

- Oils

- Fuels

*This style is not the preferred choice for steam service, but is successful when adequately compressed. Minimum recommended assembly stress = 4,800 psi. Preferred assembly stress = 6,000-10,000 psi. Gasket thickness of 1/16" strongly preferred. Retorque the bolts/studs prior to pressurizing the assembly. For saturated steam above 150psig or superheated steam, consult Quest Gasket .

ADDITIONAL INFORMATION

Contact QUEST GASKET

Aramid Fibers with an SBR Binder

The BLUE-GARD® Style 3400 is a compressed, non-asbestos gasket made from aramid fibers with an SBR binder. Its excellent sealability can drastically lower emissions levels and reduce waste in water, saturated steam*, and inert gas applications.

FEATURES AND BENEFITS

- Excellent sealability

- Improved torque retention

- Drastically lowered emissions levels

- Cuts operational costs through reduced waste, maintenance, stocked inventory, fluid loss, and energy consumption

SPECIFICATIONS

- Aramid fibers, fillers, and an SBR rubber binder

- Grey-black color

- Min. Temperature: -100°F -73°C

- Max. Temperature: 700°F 370°C

- Continuous Max: 400°F 205°C

- Max Pressure: 1200 PSI 83 bar

- Maximum PxT 1/16: 350,000 (°F x PSIG) 12,000 bar x °C

- Maximum PxT 1/8: 250,000 (°F x PSIG) 8,600 bar x °C

APPLICATIONS

- Water

- Saturated steam*

- Inert gases

*This style is not the preferred choice for steam service, but is successful when adequately compressed. Minimum recommended assembly stress = 4,800 psi. Preferred assembly stress = 6,000-10,000 psi. Gasket thickness of 1/16" strongly preferred. Retorque the bolts/studs prior to pressurizing the assembly. For saturated steam above 150 psig or superheated steam, consult Quest Gasket .

Aramid fibers with an EPDM binder

The BLUE-GARD® Style 3700 is a compressed, non-asbestos gasket made from aramid fibers with an EPDM binder. This gaskets drastically lowers emissions levels, fluid loss, and energy consumption.

FEATURES AND BENEFITS

- Excellent sealability

- Improved torque retention

- Drastically lowered emissions levels

- Cuts operational costs through reduced waste, maintenance, stocked inventory, fluid loss, and energy consumption

SPECIFICATIONS

- Available in sheet or cut gasket form

- Aramid fibers, fillers and an EPDM rubber binder

- Light grey color

- Min. Temperature: -100°F -73°C

- Max. Temperature: 700°F 371°C

- Continuous Max: 400°F 205°C

- Max Pressure: 1200 PSI 83 bar

- Maximum PxT 1/16: 350,000 (°F x PSIG) 12,000 bar x °C

- Maximum PxT 1/8: 250,000 (°F x PSIG) 8,600 bar x °C

APPLICATIONS

- Water

- Saturated steam*

- Inert gases

*This style is not the preferred choice for steam service, but is successful when adequately compressed. Minimum recommended assembly stress = 4,800 psi. Preferred assembly stress = 6,000-10,000 psi. Gasket thickness of 1/16" strongly preferred. Retorque the bolts/studs prior to pressurizing the assembly. For saturated steam above 150psig or superheated steam, consult Quest Gasket .

HT 750P PREMIUM

FEATURES AND BENEFITS

- Premium General Service Sheet Material

- Excellent tensile strength and flexibility resulting in a soft robust gasket

- Improved High Temperature rating

- Improved High Pressure rating

TYPLICAL APPLICATIONS:

- Suitable as an oil resistant gasket material for medium to high loading.

- Good resistance to water and gases, oils & fuels.

- A standard sealing material used in compressors, pipelines, transmission, gas meters and internal combustion engines.

M & Y FACTORS

| Thickness | “m” | “y” |

|---|---|---|

| In | (no unit) | psi |

| 1/16 (1.6) | 2.1 | 2000 |

| 1/8 (3.2) | 3.8 | 2000 |

SPECIFICATIONS

Construction:

- Aramid Fiber

- Mineral Fiber

- NBR Binder

Temperature:

- Maximum Continuous: 480°F (250°C)

- Maximum Peak: 750°F (400°C)

Pressure:

- Maximum 1450 psi (100 bar)

Color:

- Green with Black Branding

Certifications:

- EN13555 by AMTEC, GERMANY

- Loyd’s Registered approval for marine application

- SHELL TAT specification MESC SPE 85/300 BY AMTEC, GERMANY

- VDI Cuideline 2440 for TA-Luft by AMTEC, GERMANY

The material is suitable as a high-grade sealing product

PHYSICAL PROPERTIES

| Physical Properties | Test Method | Unit | Specified Value |

|---|---|---|---|

| Density | gm/cm³ | 1.60 - 1.90 | |

| Tensile Strength (Across Grain) | ASTM F152 | psi (n/mm²) | > 1450 (10) |

| Compressibility | ASTM F36A | % | 6.0 min |

| Recovery | ASTM F36A | % | > 50 |

| Immersion Properties | Test Method | Unit | Specified Value |

| Fluid Absorption | |||

| In ASTM Oil No. 3 | ASTM F146 | ||

| a. Increase in Thickness | % | < 10 | |

| In Water / Antifreeze | ASTM F146 | ||

| b. Increase in Thickness | % | < 15 | |

| Sealing Characteristics | Test Method | Unit | Specified Value |

| Ignition Loss | DIN 52911 | % | < 30 |

| Sealability (Nitrogen) | BS 7531 | ml/min | 0.05 |

Data is based on material thickness of 2mm.

Properties and application parameters shown throughout this data sheet are typical. Your specific application should not be undertaken without independent study and evaluation for suitability. For specific application recommendations consult QUEST. Failure to select proper sealing products could result in property damage and/or serious personal injury. Specifications are subject to change without notice; this edition cancels all previous issues.

HT 825FS FIRESAFE

FEATURES AND BENEFITS

- Premium Service Sheet Material

- Excellent tensile strength and flexibility resulting in a soft robust gasket

- Superior High-Temperature rating

- Superior High-Pressure rating

- Fire-Safe

TYPLICAL APPLICATIONS:

- An excellent material for high stress conditions.

- Offers a high media resistance to aggressive chemical in industrial applications

- Excellent sealing and torque retention properties

- Suitable for sealing oils, fuels, gases, and freons and applications in pulp and paper, pipelines, radiators, and boilers

M & Y FACTORS

| Thickness | “m” | “y” |

|---|---|---|

| In | (no unit) | psi |

| 1/16 (1.6) | 2.1 | 2000 |

| 1/8 (3.2) | 3.8 | 2000 |

SPECIFICATIONS

Construction:

- Aramid Fiber

- Mineral Fiber

- NBR Binder

- Glass Fiber

Temperature:

- Maximum Continuous: 660°F (350°C)

- Maximum Peak: 825°F (440°C)

Pressure:

- 2175 psi (150 bar)

Color:

- Red with Black Branding

Certifications:

- API 6FB Fire Safe

- EN46888 AMTEC, GERMANY

- SHELL TAT specification MESC SPE 85/300 BY AMTEC, GERMANY

- API Standard 607

- Loyd’s Registered approval for marine applications

The material is suitable as a high-grade sealing gasket material.

PHYSICAL PROPERTIES

| Physical Properties | Test Method | Unit | Specified Value |

|---|---|---|---|

| Density | gm/cm³ | 1.70 - 2.00 | |

| Tensile Strength (Across Grain) | ASTM F152 | psi (n/mm²) | > 1450 (10) |

| Compressibility | ASTM F36A | % | 5 - 15 |

| Recovery | ASTM F36A | % | > 50 |

| Immersion Properties | Test Method | Unit | Specified Value |

| Fluid Absorption | ASTM F146 | ||

| In ASTM Oil No. 3 | |||

| a. Increase in Weight | % | < 15 | |

| Increase in Thickness | % | < 10 | |

| In Fuel B | ASTM F146 | ||

| b. Increase in Weight | % | < 15 | |

| Increase in Thickness | % | < 10 | |

| In Water / Antifreeze | ASTM F146 | ||

| c. Increase in Weight | % | < 15 | |

| Increase in Thickness | % | < 10 | |

| Sealing Characteristics | Test Method | Unit | Specified Value |

| Ignition Loss | DIN 52911 | % | < 30 |

| Sealability (Nitrogen) | DIN 3535 | ml/min | 0.05 |

Data is based on material thickness of 2mm.

Properties and application parameters shown throughout this data sheet are typical. Your specific application should not be undertaken without independent study and evaluation for suitability. For specific application recommendations consult QUEST. Failure to select proper sealing products could result in property damage and/or serious personal injury. Specifications are subject to change without notice; this edition cancels all previous issues.

NA1076Compressed Sheet with Aramid Fibers, Neoprene Binder

Description and Applications

Style NA1076 sheet is a good all purpose sheet that is specifically formulated to handle a broad range of refrigerants. In addition, Style 1076 is suitable for services handling water, saturated steam, oils, fuels, mild acids and alkalies.

Construction

Style NA1076 is a compressed fiber sheet gasket material produced from a combination of aramid and other synthetic fibers and bonded with neoprene rubber (CR). It is manufactured through the hot calendar process under rigorous quality control standards that are registered under ISO-9001 certification.

Service Limits

| Temperature ºF (ºC) | Continuous Service: 392 (200) |

|---|---|

| Maximum Service: 698 (370)* | |

| Pressure psi (bar) | Vacuum to 725 (50) |

| Availability | 59 x 63 in |

| 59 x 126 in | |

| Thickness | 1/64", 1/32", 1/16", 3/32", 1/8" |

| Color | Black |

| ASTM F104 | F104-F712120-B4E99M9 |

| Typical Physical Properties: | |

|---|---|

| Density | 106 lb/ft 3 (1.70 g/cm 3 ) |

| Compressibility - ASTM F36 | 7-17% |

| Recovery - ASTM F36 | 46% |

| Tensile Strength Across Grain - ASTM F38 | 1740 psi |

| Thickness Increase - ASTM F146 - after 5hr | |

| ASTM Oil IRM 903 @ 300ºF (150ºC) | ≤30% |

| Fuel B, @ 77ºF (25ºC) |

≤20%

|

| Weight Increase - ASTM F146 - after 5hr | |

| Fuel B, @ 77ºF (25ºC) |

≤20%

|

| Creep Relaxation - ASTM F38 | 20% |

Datasheet NA1122

| Availability |

Size: 59 x 63 in

59 x 126 in |

|---|---|

| Thickness: 1/64”, 1/32”, 1/16”, 3/32”, 1/8” | |

| Temperature |

Continuous Service: 392 ºF (200ºC)

|

|

Maximum Service: 698 ºF (370ºC)

| |

| Pressure | Vacuum to 725 (50 bar) |

| Color | Black |

| ASTM Line Call Out | F104-F712120-B4E99M9 |

| Typical Physical Properties: | |

|---|---|

| Density | 106 lb/ft 3 (1.70 g/cm 3 ) |

| Compressibility - ASTM F36 J | 7-17% |

| Recovery - ASTM F36 J | min 46% |

| Creep Relaxation - ASTM F38 | 20% |

| Thickness Increase - ASTM F146 - After 5hr | |

| ASTM IRM 903 @ 300 ºF (150ºC) | ≤30% |

| ASTM Fuel B @ 77 ºF (25ºC) | ≤20% |

| Weight Increase - ASTM F146 - After 5hr | |

| Fuel B @ 77 ºF (25ºC) | ≤20% |

| Tensile Strength Across Grain | 1740 psi |

NA1080Compressed Sheet with Aramid Fibers, SBR Binder

Description and Applications

Style NA1080 has numerous applications in the process industries handling media like: mild acids and alkalis, water, brine, saturated steam, air, industrial gases, general chemicals, neutral solutions.

Construction

Style NA1080 is a compressed fiber sheet gasket material produced from a combination of Aramid Fiber, Inorganic Fillers and bonded with Styrene-Butadiene Rubber (SBR). It is manufactured under rigorous quality control standards that are registered under ISO-9001 certification.

Service Limits

| Temperature ºF (ºC) | Continuous Service: 518 (270) |

|---|---|

| Maximum Service: 716 (380) | |

| Pressure psi (bar) | Continuous Service: 725 (50) |

| Maximum Service: 1015 (70) | |

| Availability | 59 x 63 in |

| 59 x 126 in | |

| Thickness | 1/64", 1/32", 1/16", 3/32", 1/8" |

| Color | Off White |

| ASTM F104 | F712940E44M5 |

| Typical Physical Properties: | |

|---|---|

| Density | 122 lb/ft 3 (1.96 g/cm 3 ) |

| Compressibility - ASTM F36 | 7-17% |

| Recovery - ASTM F36 | 45% |

| Tensile Strength Across Grain - ASTM F38 | 2030psi (14 N/mm 2 ) |

| Ignition Loss - ASTM F495 | 28% |

| Thickness Increase - ASTM F146 - after 5hr | |

| ASTM Oil IRM 903 @ 300ºF (150ºC) | 40% |

| Fuel B, @ 77ºF (25ºC) | 20% |

| Weight Increase - ASTM F146 - after 5hr | |

| ASTM Oil IRM903 @ 300ºF (150ºC) | 30% |

| Fuel B, @ 77ºF (25ºC) | 30% |

| Creep Relaxation - ASTM F38 | 22% |

| Torque Relaxation | 37N/mm 2 |

| Sealability @ 1000psi - ASTM F37 | .25 ml/hr |

Datasheet NA1122

| Availability |

Size: 59 x 63 in

59 x 126 in |

|---|---|

| Thickness: 1/64”*, 1/8” | |

| Temperature |

Continuous Service: 518 ºF (270ºC)

|

|

Maximum Service: 716 ºF (380ºC)

| |

| Pressure | Continuous Service: 725 psi (50 bar) |

| Maximum Service: 1015 psi (70 bar) | |

| Color | Off White |

| ASTM Line Call Out | F712940E44M5 |

| Typical Physical Properties: | |

|---|---|

| Density | 122 lb/ft 3 (1.96 g/cm 3 ) |

| Compressibility - ASTM F36 J | 7-17% |

| Recovery - ASTM F36 J | min 45% |

| Tensile Strength Across Grain - ASTM F152 | 2030 psi (14 N/mm 2 ) |

| Ignition Loss | max 28% |

| Thickness Increase - ASTM F146 - After 5hr | |

| ASTM Oil IRM903 @ 300 ºF (150ºC) | max 40% |

| Fuel B @ 77 ºF (25ºC) | max 20% |

| Weight Increase - ASTM F146 - After 5hr | |

| ASTM Oil IRM903 @ 300 ºF (150ºC) | max 30% |

| Fuel B @ 77 ºF (25ºC) | max 30% |

| Creep Relaxation- ASTM F38 | 22% |

| Torque Retention (DIN 52913)- ASTM F38 | 37 N/mm 2 |

| Sealability, at 1000PSI- ASTM F37 | 0.25 ml/hr |

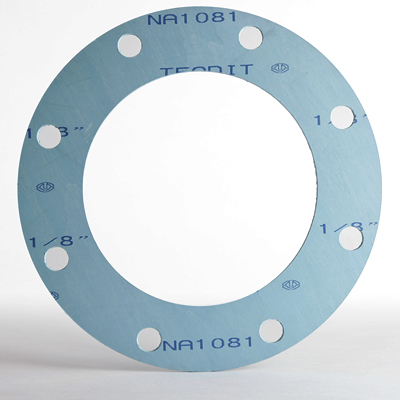

NA1081Premium Compressed Sheet with Aramid Fibers, NBR Binder

Description and Applications

Style NA1081 has numerous applications in the process industries handling media like: mild acids and alkalis, water, hydrocarbons, oils, gasoline, steam, air, industrial gases, general chemicals, neutral solutions.

Construction

Style NA1081 is a premium compressed fiber sheet gasket material produced from a combination of DuPont Kevlar®, Inorganic Fillers and bonded with Nitrile Rubber (NBR). It is manufactured under rigorous quality control standards that are registered under ISO-9001 certification.

Service Limits

| Temperature ºF (ºC) | Continuous Service: 500 (260) |

|---|---|

| Maximum Service: 752 (400) | |

| Pressure psi (bar) | Continuous Service: 725 (50) |

| Maximum Service: 1595 (110) | |

| Availability | 59 x 63 in |

| 59 x 126 in | |

| Thickness | from 1/64" to 1/8" |

| Color | Blue |

| ASTM F104 | F712220E23M5 |

| Typical Physical Properties: | |

|---|---|

| Density | 119.5 lb/ft 3 (1.92 g/cm 3 ) |

| Compressibility - ASTM F36 | 7-17% |

| Recovery - ASTM F36 | 50% |

| Tensile Strength Across Grain - ASTM F38 | 1820psi (12.5 N/mm 2 ) |

| Ignition Loss - ASTM F495 | 26% |

| Thickness Increase - ASTM F146 - after 5hr | |

| ASTM Oil IRM 903 @ 300ºF (150ºC) | 15% |

| Fuel B, @ 77ºF (25ºC) | 15% |

| Weight Increase - ASTM F146 - after 5hr | |

| ASTM Oil IRM903 @ 300ºF (150ºC) | 15% |

| Fuel B, @ 77ºF (25ºC) | 15% |

| Creep Relaxation - ASTM F38 | 22% |

| Torque Relaxation | 37N/mm 2 |

| Sealability @ 1000psi - ASTM F37 | max .2 ml/hr |

Datasheet NA1122

| Availability |

Size: 59 x 63 in

59 x 126 in |

|---|---|

| Thickness: 1/64”*, 1/8” | |

| Temperature |

Continuous Service: 500 ºF (260ºC)

|

|

Maximum Service: 752 ºF (400ºC)

| |

| Pressure | Continuous Service: 725 psi (50 bar) |

| Maximum Service: 1595 psi (110 bar) | |

| Color | Blue |

| ASTM Line Call Out F104 | F712220E23M5 |

| Typical Physical Properties: | |

|---|---|

| Density | 119.5 lb/ft3 (1.92 g/cm 3 ) |

| Compressibility - ASTM F36 J | 7-17% |

| Recovery - ASTM F36 J | min 50% |

| Tensile Strength Across Grain - ASTM F152 | 1820 psi (12.5 N/mm 2 ) |

| Ignition Loss | max 26% |

| Thickness Increase - ASTM F146 - After 5hr | |

| ASTM Oil IRM903 @ 300 ºF (150ºC) | max 15% |

| Fuel B @ 77 ºF (25ºC) | max 15% |

| Weight Increase - ASTM F146 - After 5hr | |

| ASTM Oil IRM903 @ 300 ºF (150ºC) | max 15 % |

| Fuel B @ 77 ºF (25ºC) | max 15% |

| Creep Relaxation- ASTM F38 | 22% |

| Torque Retention (DIN 52913)- ASTM F38 | 37 N/mm 2 |

| Sealability, at 1000PSI- ASTM F37 | 0.2 ml/hr |

1082 SANSanitary Service Gasket Material

Description and Applications

Drinking Water Service:

Teadit style 1082 SAN is developed to allow compliance for drinking water system components with NSF-61, from source to tap. Certification to NSF-61 provides assurance to a highest level that 1082 SAN is safe for use in drinking water service. The gasket material was also tested and found to be in conformance per US FDA 21 CFR 177.2600.

Isolation:

An added benefit is that Teadit style 1082 SAN has a strong dielectric rating, making it ideal for isolation kit applications where compressed fiber sheet gaskets can be utilized.

Construction

Teadit style 1082 SAN is specifically formulated to pass criteria established in NSF-61 for sealing materials, as well as providing excellent resistance to conductivity. Compressed Fiber Sheet technology provides mechanical and service characteristics unmatched by standard elastomeric grades.

Service Limits

| Temperature ºF (ºC) | Continuous Service: 500 (260) |

|---|---|

| Maximum Service: 752 (400) | |

| Pressure psi (bar) | Continuous Service: 1160 (80) |

| Maximum Service: 1595 (110) | |

| Availability | 59 x 63 in |

| 59 x 126 in | |

| Thickness* | 1/64", 1/32", 1/16", 1/8" |

| Color | Blue |

| ASTM F104 | F712120E12M5 |

* Other sizes are available upon request.

| Typical Physical Properties: | |

|---|---|

| Dielectric Strength- ASTM D149 | 18.5 kv/mm (1/16” thk) |

| Density | 121 lb/ft 3 (1.95 g/cm 3 ) |

| After 1 hour at 210ºF (100ºC) | |

| Compressibility - ASTM F36 | 5-15% |

| Recovery - ASTM F36 | 50% |

| Tensile Strength Across Grain - ASTM F152 | 1885 psi (13 N/mm 2 ) |

| Thickness Increase - ASTM F146 | |

| ASTM Oil IRM903 Nr. 3 5h / 300 ºF (150ºC) | 15% |

| Fuel B, @ 77ºF (25ºC) | 10% |

| Weight Increase - ASTM F146 | |

| ASTM Oil IRM903 Nr. 3 5h / 300 ºF (150ºC) | 15% |

| Fuel B, @ 77ºF (25ºC) | 10% |

Datasheet NA1122

| Availability | 59 x 63 in |

|---|---|

| 59 x 126 in | |

| Thickness* | 1/64", 1/32", 1/16", 1/8" |

| Temperature ºF (ºC) | Continuous Service: 500 (260) |

| Maximum Service: 752 (400) | |

| Pressure psi (bar) | Continuous Service: 1160 (80) |

| Maximum Service: 1595 (110) | |

| Color | Blue |

| ASTM F104 | F712120E12M5 |

* Other sizes are available upon request.

| Typical Physical Properties: | |

|---|---|

| Dielectric Strength - ASTM D149 | 18.5 kv/mm (1/16” thk) |

| Density | 121 lb/ft 3 (1.95 g/cm 3 ) |

| After 1 hour at 210ºF (100ºC) | |

| Compressibility - ASTM F36 J | 5-15% |

| Recovery - ASTM F36 J | 50% |

| Tensile Strength Across Grain - ASTM F152 | 1885 psi (13 N/mm 2 ) |

| Thickness Increase - ASTM F146 | |

| ASTM Oil IRM903 Nr. 3 5h / 300 ºF (150ºC) | 15% |

| Fuel B, @ 77ºF (25ºC) | 10% |

| Weight Increase - ASTM F146 | |

| ASTM Oil IRM903 Nr. 3 5h / 300 ºF (150ºC) | 15% |

| Fuel B, @ 77ºF (25ºC) | 10% |

Utility-Grade

Aramid fibers with a nitrile binder

Style 2900 is able to withstand high temperature, whether continuous or in thermal cycling conditions and is ideal for use in general utility services, including aliphatic hydrocarbons, oils and gasoline.

FEATURES AND BENEFITS

- Excellent sealability

- Improved thermal stability

- Good for general service

SPECIFICATIONS

- Min. Temperature: -100°F / -75°C

- Max. Temperature: 700°F / 371°C

- Continuous Max: 400°F / 205°C

- Max Pressure: 1000 PSI / 70 bar

- Maximum PxT 1/16: 350,000(°F x PSIG) / 12,000 bar x °C

- Maximum PxT 1/8: 250,000(°F x PSIG) / 8,600 bar x °C

APPLICATIONS

- Water

- Aliphatic hydrocarbons

- Oils

- Gasoline

High temperature gasket material made with aramid fibers and nitrile binder

Style 2950 features a nitrile binder that makes it an ideal choice for aliphatic hydrocarbon, oil and gasoline applications.

FEATURES AND BENEFITS

- Excellent sealability

- Improved thermal stability

- Good for general service

SPECIFICATIONS

- Min. Temperature: -100°F -75°C

- Max. Temperature: 700°F 371°C

- Continuous Max: 400°F 205°C

- Max Pressure: 1000 PSI 70 bar

- Maximum PxT 1/16: 350,000 (°F x PSIG) 12,000 (bar x °C)

- Maximum PxT 1/8: 250,000 (°F x PSIG) 8,600 (bar x °C)

APPLICATIONS

- Water

- Aliphatic hydrocarbons

- Oils

- Gasoline

NA 1001Compressed Sheet with Aramid Fibers, NBR Binder

Description and Applications

Style NA1001 is a very good general service gasket material that has numerous applications in the process industries and in the water and wastewater industry. It is also commonly used in equipment such as valves and pumps. Style NA1001 is suitable for service handling the following general media categories:

- Mild inorganic acids

- Aliphatic solvents

- General chemicals

- Water

- Vegetable oils

- Air

- Animal oil

- Refrigerants

- Diluted alkalis

- Synthetic oils

- Mild organic acids

- Industrial oils

- Vegetable Solutions

- Brine

- Petroleum and Derivatives

Construction

Style NA1001 is a compressed fiber sheet gasket material produced from a combination of aramid and other synthetic fibers and bonded with nitrile rubber (NBR). It is manufactured through the hot calendar process under rigorous quality control standards that are registered under ISO-9001 certification.

Service Limits

| Temperature ºF (ºC) | Continuous Service: 464 (240) |

|---|---|

| Maximum Service: 750 (400) | |

| Pressure psi (bar) | Continuous Service: 725 (50) |

| Maximum Service: 1595 (110) | |

| Availability | 59 x 63 in |

| 59 x 126 in | |

| 118 x 126 in | |

| Thickness | 1/64", 1/32", 1/16", 3/32", 1/8" |

| Color | Green, White, or Blue |

| ASTM F104 | F712120E22M5 |

| Typical Physical Properties: | |

|---|---|

| Density | 109 lb/ft3 (1.7 g/cm3) |

| Compressibility - ASTM F36 | 7-17% |

| Recovery - ASTM F36 | min 45% |

| Tensile Strength Across Grain - ASTM F38 | 1670psi (11.5 N/mm 2 ) |

| Ignition Loss - ASTM F495 | max 34% |

| Thickness Increase - ASTM F146 - after 5hr | |

| ASTM Oil IRM 903 @ 300ºF (150ºC) | max 12% |

| Fuel B, @ 77ºF (25ºC) | max 10% |

| Weight Increase - ASTM F146 - after 5hr | |

| ASTM Oil IRM903 @ 300ºF (150ºC) | max 15% |

| Fuel B, @ 77ºF (25ºC) | max 15% |

| Creep Relaxation - ASTM F38 | 25% |

| Torque Retention (DIN 52913) | 28N/mm 2 |

| Sealability @ 1000psi - ASTM F37 | max .25 ml/hr |

Datasheet NA1001

| Availability | 59 x 63 in |

|---|---|

| 59 x 126 in | |

| 118 x 126 in | |

| Temperature ºF (ºC) | Continuous Service: 464 (240) |

| Maximum Service: 750 (400) | |

| Pressure psi (bar) | Continuous Service: 725 (50) |

| Maximum Service: 1595 (110) | |

| Thickness | 1/64", 1/32", 1/16", 3/32", 1/8" |

| Color | Green - NA1001G |

| Blue - NA1001BL | |

| White - NA1001W | |

| ASTM Line Call Out F104 | F712120E22M5 |

| Typical Physical Properties: | |

|---|---|

| Density | 109 lb/ft 3 (1.75 g/cm 3 ) |

| Compressibility - ASTM F36 J | 7-17% |

| Recovery - ASTM F36 J | min 45% |

| Tensile Strength Across Grain - ASTM F38 | 1670psi (11.5 N/mm 2 ) |

| Ignition Loss - ASTM F495 | max 34% |

| Thickness Increase - ASTM F146 - after 5hr | |

| ASTM IRM 903 @ 300 ºF (150ºC) | max 12% |

| Fuel B, @ 77ºF (25ºC) | max 10% |

| Weight Increase - ASTM F146 - after 5hr | |

| ASTM Oil IRM903 @ 300ºF (150ºC) | max 15% |

| ASTM Fuel B, @ 77ºF (25ºC) | max 15% |

| Creep Relaxation - ASTM F38 | 25% |

| Torque Retention (DIN 52913) | 28N/mm 2 |

| Sealability @ 1000psi - ASTM F37 | max 0.25 ml/hr |

Carbon Fibers with a SBR Binder

Style 9800 gasket is a high temperature gasketing composed of carbon fibers with an SBR binder. This high performance material maintains its seal during pressure and temperature fluctuations, reducing leakage rates and maintenance time.

FEATURES AND BENEFITS

- Excels in the harshest conditions - intense heat, high pressure, saturated steam* and hot oils

- Laboratory tested for fire safety

- Maintains effective seal during pressure and temperature fluctuations

- Superior torque retention lowers leakage rates and reduces maintenance time

- Convenient

- Flexible material is easy to handle and cut

- Sheet sizes from 60” x 60” (1.5m x 1.5m) up to 150” x 150” (3.8 m x 3.8 m) minimize waste and inventory costs

*Minimum recommended assembly stress = 4,800psi. Preferred assembly stress = 6,000 - 10,000psi. Gasket thickness of 1/16” strongly preferred. Retorque the bolts/studs prior to pressurizing the assembly. For saturated steam above 150 psig or superheated steam, consult Garlock Engineering.

SPECIFICATIONS

- Available in sheet or cut gasket form

- Min. Temperature: -100°F / -73°C

- Max. Temperature: 900°F / 482°C

- Continuous Max: 650°F / 343°C

- Max Pressure: 2000 PSI / 138 bar

- Maximum PxT 1/16: 700,000 (°F x PSIG) / 25,000 (°C x bar)

- Maximum PxT 1/8: 350,000 (°F x PSIG) / 12,000 (°C x bar)

APPLICATIONS

- Saturated steam*

- Water

- Inert gases

*Minimum recommended assembly stress = 4,800psi. Preferred assembly stress = 6,000 - 10,000psi. Gasket thickness of 1/16” strongly preferred. Retorque the bolts/studs prior to pressurizing the assembly. For saturated steam above 150 psig or superheated steam, consult Garlock Engineering.

Carbon Fibers with a Nitrile Binder

Style 9850 gasket is composed of carbon fibers with a nitrile binder. This high temperature gasket has a long-lasting seal, which minimizes cold flow and creep relaxation problems.

FEATURES AND BENEFITS

- Excels in the harshest conditions - intense heat, high pressure, saturated steam* and hot oils

- Laboratory tested for fire safety

- Long-lasting seal

*Minimum recommended assembly stress = 4,800psi. Preferred assembly stress = 6,000 - 10,000psi. Gasket thickness of 1/16” strongly preferred. Retorque the bolts/studs prior to pressurizing the assembly. For saturated steam above 150 psig or superheated steam, consult Garlock Engineering.

SPECIFICATIONS

- Min. Temperature: -100°F / -73°C

- Max. Temperature: 900°F / 482°C

- Continuous Max: 650°F / 343°C

- Max Pressure: 2000 PSI / 138 bar

- Maximum PxT 1/16: 700,000 (°F x PSIG) / 25,000 (°C x bar)

- Maximum PxT 1/8: 350,000 (°F x PSIG) / 12,000 (°C x bar)

APPLICATIONS

-

Ideal for standard ANSI flanged

connectors, as well as turbine

crossover piping connectors - Power generation

- Chemical processing

- Hydrocarbon processing

- Other industries

- Saturated Steam*

- oils

- gasoline

- water

- Aliphatic Hydrocarbons

- Most Refrigerants

Media

*Minimum recommended assembly stress = 4,800psi. Preferred assembly stress = 6,000 - 10,000psi. Gasket thickness of 1/16” strongly preferred. Retorque the bolts/studs prior to pressurizing the assembly. For saturated steam above 150 psig or superheated steam, consult Garlock Engineering.

ADDITIONAL INFORMATION

Contact QUEST GASKET

Graphite fibers with a nitrile binder

Style 9900 gasket is composed of graphite fibers with a nitrile binder, allowing it to withstand extreme conditions. This high temperature gasket has passed Garlock® fire tests and is ABS Fire Safe Type Approved.

FEATURES AND BENEFITS

- Withstands extreme temperatures and pressures, as well as many chemicals

- Passed Garlock® Fire tests, and is ABS Fire-Safe Type Approved

- Long-lasting seal

SPECIFICATIONS

- Available in sheet or cut gasket form

- Min. Temperature: -100°F / -73°C

- Max. Temperature: 1000°F / 537°C

- Continuous Max: 650°F / 343°C

- Max Pressure: 2000 PSI / 138 bar

- Maximum PxT 1/16: 700,000 (°F x PSIG) / 25,000 (°C x bar)

- Maximum PxT 1/8: 350,000 (°F x PSIG) / 12,000 (°C x bar)

APPLICATIONS

- Ideal for standard ANSI flanged connectors, as well as turbine crossover piping connectors

- Power generation

- Chemical processing

- Hydrocarbon processing

- Other industries

- Steam*

- oils

- Grease

- water

Media

*Minimum recommended assembly stress = 4,800psi. Preferred assembly stress = 6,000-10,000psi. Gasket thickness of 1/16" strongly preferred. Retorque the bolts/studs prior to pressurizing the assembly. For saturated steam above 150psig, consult Garlock® Engineering.

NA1100Compressed Sheet with Carbon FIber, NBR Binder

Description and Applications

Style NA1100 is a premium grade, multi-service gasket sheet, designed to handle the extremes of pressure and temperature, and it cuts very easily and cleanly. The versatility of this sheet enables a plant to standardize on one sheet for a multitude of applications and avoid the confusion of having to choose from several different sheets. NA1100 is suitable for service handling the following general media categories:

Construction

Style NA1080 is a compressed fiber sheet gasket material produced from a combination of Aramid Fiber, Inorganic Fillers and bonded with Styrene-Butadiene Rubber (SBR). It is manufactured under rigorous quality control standards that are registered under ISO-9001 certification.

- Mild inorganic acids

- Saturated steam

- Aliphatic solvents

- Water

- Vegetable oils

- Air

- Animal oil

- Refrigerants

- Diluted alkalis

- Synthetic oils

- Mild organic acids

- Industrial gases

- Neutral solutions

- Brine

- Petroleum and Derivatives

Construction

Style NA1100 is a compressed fiber sheet gasket material produced from carbon fibers and graphite, bonded with nitrile rubber (NBR). It is manufactured through the hot calendar process under rigorous quality control standards that are registered under ISO- 9001 certification. Teadit style NA1100 is also available wire reinforced.

Service Limits

| Temperature ºF (ºC) | Continuous Service: 518 (270) |

|---|---|

| Maximum Service: 842 (450) | |

| Pressure psi (bar) | Continuous Service: 1015 (70) |

| Maximum Service: 1885 (130) | |

| Availability | 59 x 63 in |

| 118 x 126 in | |

| Thickness | 1/64", 1/32", 1/16", 3/32", 1/8" |

| Color | Black |

| ASTM F104 | F712120E23M6 |

| Typical Physical Properties: | |

|---|---|

| Density | 106 lb/ft 3 (1.7 g/cm 3 ) |

| Compressibility - ASTM F36 | 5-15% |

| Recovery - ASTM F36 | 50% |

| Tensile Strength Across Grain - ASTM F152 | 2175psi (15 N/mm 2 ) |

| Ignition Loss - ASTM F495 | 50% |

| Thickness Increase - ASTM F146 - after 5hr | |

| ASTM Oil IRM 903 @ 300ºF (150ºC) | 15% |

| Fuel B, @ 77ºF (25ºC) | 15% |

| Weight Increase - ASTM F146 - after 5hr | |

| ASTM Oil IRM903 @ 300ºF (150ºC) | 15% |

| Fuel B, @ 77ºF (25ºC) | 15% |

| Creep Relaxation - ASTM F38 | 22% |

| Torque Relaxation | 35N/mm 2 |

| Sealability @ 1000psi - ASTM F37 | 0.2 ml/hr |

Datasheet NA 1100

| Availability | 59 x 63 in |

|---|---|

| 118 x 126 in | |

| Thickness | 1/64", 1/32", 1/16", 3/32", 1/8" |

| Temperature ºF (ºC) | Continuous Service: 518 (270) |

| Maximum Service: 842 (450) | |

| Pressure psi (bar) | Continuous Service: 1015 (70) |

| Maximum Service: 1885 (130) | |

| Color | Black |

| ASTM Line Call Out F104 | F712120E23M6 |

| Typical Physical Properties: | |

|---|---|

| Density | 106 lb/ft 3 (1.7 g/cm 3 ) |

| Compressibility - ASTM F36 J | 5-15% |

| Recovery - ASTM F36 J | min 50% |

| Tensile Strength Across Grain - ASTM F152 | 2175 psi (15 N/mm 2 ) |

| Ignition Loss - F495 | max 50% |

| Thickness Increase - ASTM F146 - after 5hr | |

| ASTM IRM 903 @ 300 ºF (150ºC) | max 50% |

| Fuel B, @ 77ºF (25ºC) | max 15% |

| Weight Increase - ASTM F146 - after 5hr | |

| ASTM Oil IRM903 @ 300ºF (150ºC) | max 15% |

| Fuel B, @ 77ºF (25ºC) | max 15% |

| Creep Relaxation - ASTM F38 | 22% |

| Torque Retention (DIN 52913)- ASTM F38 | 35 N/mm 2 |

| Sealability @ 1000psi - ASTM F37 | 0.2 ml/hr |

THERMa-PUR® Style 4122 High Temperature Cut Gaskets and Sheets

THERMa-PUR® is yet another innovative Garlock sealing solution that provides more than just temperature resistance. Style 4122 is designed for use in high temperature sealing applications. It is produced using an environmentally friendly solvent-free process and combines a unique formulation with Garlock’s traditional quality. THERMa-PUR® out performed vermiculite based gaskets in laboratory testing, showing significantly less leakage even in extreme thermal cycling condition.

FEATURES AND BENEFITS

- Extreme Temperature - Able to withstand high temperature, whether continuous or in thermal cycling conditions

- Chemical Resistance - Proprietary formulation is resistant to a broad range of chemicals: Titanium Tetrachloride, molten salts and other heavy oxidizers

- Oxidation Resistance - Contains proprietary materials that provide improved weight loss characteristics over other high-temperature solutions

- Hydrophobic (water resistant) - Resists water and provides electrical isolation thus reducing the possibility of corrosion between flanges made of dissimilar metals

- Easy Release from Flanges - Does not stick to flanges making removal of gaskets easy and fast

SPECIFICATIONS

- Continuous Max: 1832°F / 1000°C

- Pressure: 500(34.5) psig(bar)

- Chemical Compatibility- Please consult Applications Engineering

- Gasket Factor ‘M’- 3.0

- Gasket Factor ‘Y’- 10,000

- ASTM Test Method F36 Compressibility Range 35-45%

- ASTM Test Method F36 Recovery 18%

- ASTM F38 Creep Relaxation 25%

- ASTM F152 Tensile with insert 1,200 (8.3) psi (N/mm2)

- ASTM F1315 Density 85 (1.36) lbs./ft3 (grams/cm3)

- ASTM D149 Dielectric Properties 100 volts/mil.

Typical Physical Properties

APPLICATIONS

- Marine and Land-based Exhaust Systems

- Biomass Gasification Process

- Oil and Gas Production

- Mineral and Fertilizer Processing

- Incineration Process

- Co-generation Systems

- Turbochargers Equipment

- Process Drying Equipment

CONFIGURATIONS

- Cut and Sheet Gaskets (Style 4122-FC)

- THERPHONIC® Corrugated Metal Gasket (Style 4122-CMG)

- Kammprofile (Style 4122-KAMM)

- THERMa-PUR® Spiral Wound (Style 4122-SW) available in filler only or filled faces

Inorganic fibers with a nitrile binder

Garlock® Inorganic Fiber Gasketing offers excellent thermal stability with minimal weight loss, reduced creep relaxation and improved torque retention. The inorganic fibers have excellent thermal and oxidation resistance, withstanding a continuous operating temperature of up to 550° F (290° C), and maximum spike of 800° F (425° C).

FEATURES AND BENEFITS

- Tighter seal

- Excellent thermal stability with minimal weight loss

- Temperature resistant

- Withstand a continuous operating temperature of up to 550° F (290° C), and maximum spike of 800° F (425° C)

- IFG® 5500 has passed the Garlock Fire Test and is ABS Fire-Safe Type Approved.

SPECIFICATIONS

- Available in sheet or cut gasket form

- Min. Temperature: -100°F / -73°C

- Max. Temperature: 800° F / 427° C

- Continuous Max: 550° F / 288° C

- Max. Pressure: 1,200 PSI / 83 bar

- Maximum PxT 1/16: 400,000 (°F x PSIG) / 14,000 (°C x bar)

- Maximum PxT 1/8: 275,000 (°F x PSIG) / 9,600 (°C x bar)

APPLICATIONS

- Water

- Aliphatic hydrocarbons

- Oils

- Gasoline

- Saturated steam*

- Inert gases

- Most refrigerants

*Minimum recommended assembly stress = 4,800psi. Preferred assembly stress = 6,000-10,000psi. Gasket thickness of 1/16" strongly preferred. Retorque the bolts/studs prior to pressurizing the assembly. For saturated steam above 150psig or superheated steam, consult Garlock Engineering.

NA1088Controlled Swell Sheet

Description and Applications

Style NA1088 is used in difficult to seal applications where inadequate bolt loading or flange surface conditions are not ideal, in low to moderate flange load conditions.

- Petroleum and Derivatives

- Synthetic oils

- Aliphatic solvents

- Mild organic acids

- Water

- Air

- Coolants

- Refrigerants

- Vegetable oils

- Animal oils

Construction

Style NA1088 is a high density, controlled swell sheet gasket material with a proprietary binder and reinforced with a synthetic/inorganic fiber blend. It is designed for demanding applications requiring excellent sealablity, torque retention, recovery, and conformability to uneven flange surfaces. The material provides a controlled swell in the presence of oils, fuels, lubricants, and water/coolant. It is used in heavy duty and industrial oil sealing applications such as diesel engine oil pans and front covers, compressors, generators, pumps, valves, gear boxes and housings, transformer, sight glass, man/hand-hole covers. The following specification values are for 0.8mm (0.031”) gauge material.

| Availability | Size: 59 x 63 in |

|---|---|

| Thickness: 1/16”, 3/32”, 1/8” | |

| Temperature | Continuous Service: 400ºF (205ºC) |

| Maximum Service: 650º F (343ºC)* | |

| Pressure | Continuous Service: 500 psi (34.5 bar) |

| Maximum Service: 1000 psi (69 bar)* | |

| Color | Beige/ Off White |

| Typical Physical Properties: | |

|---|---|

| Density | 103 lb/ft3 (1.65 g/cm3) |

| Compressibility - ASTM F36 | 7-17% |

| Recovery - ASTM F36 J | min 45% |

| Creep Relaxation- ASTM F38 | 20% |

| Sealability @ 500psi - ASTM F37A | <0.05 ml/h |

| Sealability @ 3000psi - ASTM F37B | <0.05 ml/h |

| ASTM F146 IRM 903 - 150ºC (300ºF) after 5h | |

| Weight Increase | 30-50% |

| Thickness Increase | 30-50% |

| ASTM F146 Distilled Water - Room Temperature after 5h | |

| Weight Increase | 10-35% |

| Thickness Increase | 10-35% |

| ASTM F146 Distilled Water - 100ºC (212º F) after 22h | |

| Weight Increase | 10-35% |

| Thickness Increase | 10-35% |

Properties and application parameters shown throughout this data sheet are typical. Your specific application should not be undertaken without independent study and evaluation for suitability. For specific application recommendations consult TEADIT. Failure to select proper sealing products could result in property damage and/or serious personal injury. Specifications are subject to change without notice; this edition cancels all previous issues.

NA1122High Performance Steam Service Sheet, NBR Binder

Description and Applications

Teadit style NA1122 was developed to exhibit superior thermal stability during extreme thermal cycling applications. It is specifically recommended for saturated and superheated steam services but has also proven itself to be very effective in sealing liquid petroleum derivates, ethanol, chemical products and other fluids. Field tests have validated the results found in our laboratories and have confirmed the higher performance capabilities of NA1122.

Construction

Teadit style NA1122 was developed to exhibit superior thermal stability during extreme thermal cycling applications. It is specifically recommended for saturated and superheated steam services. Field tests have validated the results found in our laboratories and have confirmed the higher performance capabilities of NA1122.

Service Limits

| Temperature ºF (ºC) | Continuous Service: 806 (430) |

|---|---|

| Maximum Service: 1022 (550) | |

| Pressure psi (bar) | Continuous Service: 1480 (102) |

| Maximum Service: 2177 (150) | |

| Availability | 59 x 63 in |

| 59 x 126 in | |

| Thickness | 1/64", 1/32", 1/16", 3/32", 1/8" |

| Color | Black |

| ASTM F104 | F712140E33-M9 |

| Typical Physical Properties: | |

|---|---|

| Density | 91.14 lb/ft3 (1.46 g/cm3) |

| Compressibility - ASTM F36 | 12-22% |

| Recovery - ASTM F36 J | 40% |

| Tensile Strength Across Grain - ASTM F152 | 1305psi (9 N/mm2) |

| Thickness Increase - ASTM F146 - after 5hr | |

| ASTM Oil IRM 903 @ 300ºF (150ºC) | 15% |

| Fuel B, @ 77ºF (25ºC) | 15% |

| Weight Increase - ASTM F146 - after 5hr | |

| ASTM Oil IRM903 @ 300ºF (150ºC) | 30% |

| Fuel B, @ 77ºF (25ºC) | 20% |

| Torque Retention (DIN 52913) | 43MPa |

Datasheet NA1122

| Availability |

Size: 59 x 63 in

59 x 126 in |

|---|---|

| Thickness: 1/64” to 1/8” | |

| Temperature | Continuous Service: 8060 F (430ºC) |

| Maximum Service: 10220 F (550ºC) | |

| Pressure | Continuous Service: 1480 psi (102 bar) |

| Maximum Service: 2177 psi (150 bar) | |

| Thickness | 1/64", 1/32", 1/16", 3/32", 1/8" |

| Color | Black |

| ASTM F104 | F712140E33-M9 |

| Typical Physical Properties: | |

|---|---|

| Density ASTM F36 - @ 1/32” thk | 99.88 lb/ft3 (1.6 g/cm3) |

| Density ASTM F36 - @ 1/16” thk | 91.14 lb/ft3 (1.46 g/cm3 |

| Compressibility - ASTM F36 J - @ 1/32” thk | 7-17% |

| Compressibility - ASTM F36 J - @ 1/16” thk | 12-22% |

| Recovery - ASTM F36 J | min 40% |

| Tensile Strength Across Grain - ASTM F152 | 1305 psi (9 N/mm2) |

| Thickness Increase - ASTM F146 - After 5hr | |

| ASTM IRM903 @ 300º F (150ºC) | max 15% |

| Fuel B, @ 77ºF (25ºC) | max 15% |

| Weight Increase - ASTM F146 - After 5 hr | |

| ASTM IRM903 @ 300 ºF (150ºC) | max 30% |

Aramid fibers with a proprietary rubber binder.

The BLUE-GARD® Style 3000 compressed fiber gasketing is made with aramid fibers with an NBR binder. The MULTI-SWELL™ 3760 is the ultimate problem solver for those lightweight flanges and covers where nuisance oil and water leaks plague most industrial facilities. Unlike traditional vegetable fiber and cork gaskets that allow water and oil to “wick” through the body of the gasket, the MULTI-SWELL absorbs the media at the inside edge, swells, and creates a tighter, long term seal.

FEATURES AND BENEFITS

- Creates compressive load in lightweight flanges in oil and water service

- More universal than gaskets that swell in oil only — reduces inventory

- More compressible than standard fiber gaskets and seals with low load

- Easy to cut and handle — extremely flexible, minimizes waste

- Replaces vegetable fiber gaskets in many applications — won't weep, improving plant safety

- Seals flanges in "less than perfect" conditions minimizing maintenance

- Specify 3760-U for applications requiring NSF 61 approved gaskets (Drinking Water)

SPECIFICATIONS

- Materials of Construction: Synthetic fiber sheet with a proprietary rubber binder

- Blue color

- Min. Temperature: -100°F / -73°C

- Continuous Max: 400°F / 205°C

- Max. Pressure: 500 PSI 34.5 bar

- Maximum PxT 1/16: 150,000 (°F x PSIG) 5,100 (°C x bar)

- Maximum PxT 1/8: 100,000 (°F x PSIG) 3,400 (°C x bar)

APPLICATIONS

- Compressors

- Generators

- Pumps

- Gear Boxes

- Cast Water Flanges

- Transformers

- Sight Glasses

- Access Covers

- Handhole/Manhole

NA1088Controlled Swell Sheet

Description and Applications

Style NA1088 is used in difficult to seal applications where inadequate bolt loading or flange surface conditions are not ideal, in low to moderate flange load conditions.

- •Petroleum and Derivatives

- Synthetic oils

- Aliphatic solvents

- Mild organic acids

- Water

- Coolants

- Refrigerants

- Vegetable oils

- Animal oils

Construction

Style NA1088 is a high density, controlled swell sheet gasket material with a proprietary binder and reinforced with a synthetic/inorganic fiber blend. It is designed for demanding applications requiring excellent sealablity, torque retention, recovery, and conformability to uneven flange surfaces. The material provides a controlled swell in the presence of oils, fuels, lubricants, and water/coolant. It is used in heavy duty and industrial oil sealing applications such as diesel engine oil pans and front covers, compressors, generators, pumps, valves, gear boxes and housings, transformer, sight glass, man/hand-hole covers. The following specification values are for 0.8mm (0.031”) gauge material.

Service Limits

| Temperature ºF (ºC) | Continuous Service: 400 (205) |

|---|---|

| Maximum Service: 650 (343)* | |

| Pressure psi (bar) | Continuous Service: 500 (34.5) |

| Maximum Service: 1000 (69) | |

| Sheet size | 59 x 63 in |

| Thickness | 1/32", 1/16", 3/32", 1/8" |

| Color | Beige/Off White |

| Typical Physical Properties: | |

|---|---|

| Density | 103 lb/ft3 (1.65 g/cm3) |

| Compressibility - ASTM F36 | 7-17% |

| Recovery - ASTM F36 J | min 45% |

| Creep Relaxation - ASTM F38 | 20% |

| Sealability @ 500psi - ASTM F37A | < 0.05 ml/h |

| Sealability @ 3000psi - ASTM F37B | < 0.05 ml/h |

| ASTM F146 IRM 903 - 150ºC (300ºF) after 5h | |

| Weight Increase | 30-50% |

| Thickness Increase | 30-50% |

| ASTM F146 Distilled Water - Room Temperature after 5h | |

| Weight Increase | 10-35% |

| Thickness Increase | 10-35% |

| ASTM F146 Distilled Water - Room Temperature after 5h | |

| Weight Increase | 10-35% |

| Thickness Increase | 10-35% |

Datasheet NA1122

| Availability |

Size: 59 x 63 in

Thickness: 1/16”, 3/32”, 1/8” |

|---|---|

| Thickness: 1/64” to 1/8” | |

| Temperature | Continuous Service: 400ºF (205ºC) |

| Maximum Service: 650º F (343ºC)* | |

| Pressure | Continuous Service: 500 psi (34.5 bar) |

| Maximum Service: 1000 psi (69 bar)* | |

| Color | Beige/ Off White |

| Typical Physical Properties: | |

|---|---|

| Density | 103 lb/ft3 (1.65 g/cm3) |

| Compressibility - ASTM F36 J | 7-17% |

| Recovery - ASTM F36 J | min 45% |

| Creep Relaxation - ASTM F38 | 20% |

| Sealability @ 500psi - ASTM F37A | < 0.05 ml/h |

| Sealability @ 3000psi - ASTM F37B | < 0.05 ml/h |

| ASTM F146 IRM 903 - 150ºC (300ºF) after 5h | |

| Weight Increase | 30-50% |

| Thickness Increase | 30-50% |

| ASTM F146 Distilled Water - Room Temperature after 5h | |

| Weight Increase | 10-35% |

| Thickness Increase | 10-35% |

| ASTM F146 Distilled Water - 100ºC (212º F) after 22h | |

| Weight Increase | 10-35% |

| Thickness Increase | 10-35% |