QUESTGUARD

QUESTGUARD TM GRE Glass Reinforced Epoxy with Sealing Element

FEATURES

- Designed for electrical flange isolation and corrosion control on pipes containing water/wastewater, gas, natural gas, oil and other hydrocarbon based medias.

- Temperatures up to 302°F (150°C).

- Available for Type E (Full Face), Type F (Raised Face) and Ring Type Joint flanges.

- Sizes from 1/2" to 120", ANSI 150-1500# and API 2-5K.

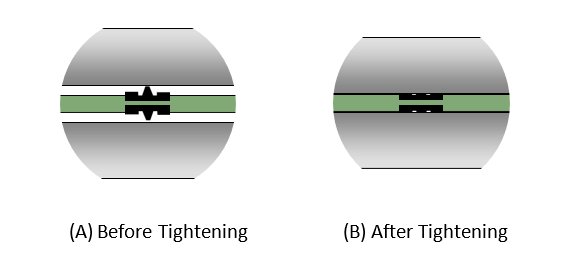

- Low Bolt Load—Proven engineered design to optimize each seal's elastic memory, the w—shaped sealing element guarantees low bolt load requirements and high sealing reliability.

- Available with a variety of retainers and seal elements.

ADVANTAGES:

- Can be utilized with mismatched for misaligned flanges.

- Can be used in place of RTJ or BX rings.

- Little initial torque required, no re-torquing required, reducing human error during installation

- Seal design tested for high pressures.

- Reusable

- Limited seal exposure, compensates for pressure fluctuations, vibrations, and temperature variations

- Wide selection of materials, high dielectric strength, and low installation maintenance costs.

- Gaskets through 144"

SPECIFICATIONS

| G-10 STANDARD RETAINER | ||||

|---|---|---|---|---|

| NEMA Grade Compression Glass-Reinforced Epoxy Laminate Material: | ||||

| Compressive Strength | 65,000 PSI | |||

| Max. Continuous Operating Temp | 302 °F (150 °C) | |||

| Water Absorption | 0.05% | |||

| Flexural Strength | 65,000 PSI | |||

| Tensile Strength | 50,000 PSI | |||

| Bond Strength | 2,600 lb | |||

| Shear Strength | 22,000 lb | |||

| SLEEVE AND WASHER MATERIALS | ||||

| SLEEVE MATERIALS |

Dielectric Strength |

Water Absorption |

Max Operating Temperate |

|

| Volts/Mil | % | °F | °C | |

| Minlon | 1,200 | 0.22 | 250 | 121 |

| Mylar | 4,000 | 0.80 | 300 | 149 |

| Nomex | 500 | - | 450 | 232 |

| G10 | 800 | 0.10 | 302 | 150 |

| G3 | 375 | 2.00 | 347 | 175 |

| G7 | 350 | 0.19 | 428 | 220 |

| G11 | 550 | 0.08 | 400 | 205 |

| SEALING MATERIALS | ||||

| SEALING MATERIALS |

Min Operating Temperature |

Max Operating Temperate |

||

| °F | °C | °F | °C | |

| Nitrile | -60 | -51 | 240 | 115 |

| Viton® | -75 | -59 | 400 | 204 |

| EPDM | -40 | -40 | 250 | 121 |

| Teflon® | -100 | -73 | 450 | 232 |

|

||||

Properties and application parameters shown throughout this data sheet are typical. Your specific application should not be undertaken without independent study and evaluation for suitability. For specific application recommendations consult QUEST. Failure to select proper sealing products could result in property damage and/or serious personal injury. Specifications are subject to change without notice; this edition cancels all previous issues.

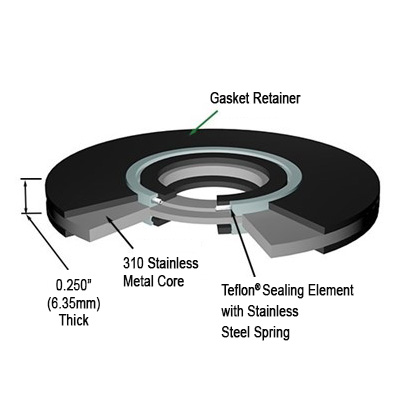

QUESTGUARD® CSA 316SS Glass Reinforced Epoxy with Teflon Sealing Element

The QUESTGUARD® CSA Gasket is a reliable gasket for isolating and sealing in severe service applications. It ensures zero leakage for flanges, suitable for services up to ANSI 2500# and API 15,000# classes. Designed for harsh environments with hydrocarbons, it features a PTFE spring-energized face seal, compressed glass laminate, and stainless steel core. Its pressure-activated sealing requires less bolt stress than standard gaskets. The inner diameter matches flange bore dimensions to prevent turbulent flow and corrosion. It's reusable with a replaceable sealing element.

FEATURES

- Exceptionally dependable for iso- lating and sealing purposes for se- vere service applications.

- Highly suitable for all severe service applications up to and including ANSI 2500# and API 15,000# classes.

- Zero-free leaks for high sulfur con- tent crude oil or H2S gas fugitive emissions, proven through multiple applications.

APPLICATIONS:

- Flange isolation with true cathodic protection.

- Isolating dissimilar metals to prevent galvanic corrosion.

- Wellhead isolation from interconnected flow lines.

- Mating mismatched dissimilar flanges.

- Eliminate turbulence and flow-induced erosion in RTJ flanges.

- Protect against corrosion on uncoated or scarred flange faces

- Seal between flanges subjected to vibration/cavitation.

- Eliminate corrosion in RTJ flange cavities with hostile chemicals.

SPECIFICATIONS

| G-10 Standard SSA S/S Retainer Specification | ||||

|---|---|---|---|---|

| NEMA Grade Compression Glass-Reinforced Epoxy Laminate Material: | ||||

| Compressive Strength | 65,000 PSI | |||

| Dielectric Strength | 750-800 VPM | |||

| Max. Continuous Operating Temp | 302 °F (150 °C) | |||

| Water Absorption | 0.05% | |||

| Flexural Strength | 65,000 PSI | |||

| Tensile Strength | 50,000 PSI | |||

| Bond Strength | 2,600 lb | |||

| Shear Strength | 22,000 lb | |||

| G-10 Standard SSA S/S Retainer Specification | ||||

| G-11 Optional SSA S/S Retainer Specification | ||||

| Compressive Strength | 50,000 PSI | |||

| Dielectric Strength | 500 VPM | |||

| Max. Continuous Operating Temp | 390 °F (177 °C) | |||

| Water Absorption | 0.085% | |||

| Flexural Strength | 57,000 PSI | |||

| Tensile Strength | 41,000 PSI | |||

| Bond Strength | 2,200 lb. | |||

| Shear Strength | 21,200 lb. | |||

| SEALING ELEMENT | ||||

| The sealing element provides a barrier that pre- vents penetration by any substance. The glass com- posite retainer holds the seal in a static, fully en- capsulated manner. Dual spring-energized PTFE seals are available for very high pressures or large diameter flanges. | ||||

|

PTFE Seal Material: PTFE (Spring-Energized) Designed for multiple applications, the helical wound spring provides radial load. Encapsulation in the seal groove prevents creep or cold flow. The PTFE spring-energized sealing element, made from specially formulated PTFE, has a wider surface area for a constant seal. Temperature Range: -250 °F to +350 °F Optional: Viton Seal Material Temperature Range: -15 °F to 350 °F Isolating Sleeve Options

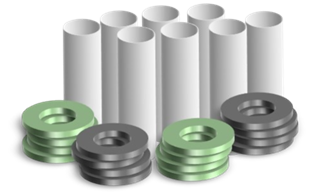

Rating for Resistance to crushing, cracking, breaking and thread pinch:

Isolating Washers

Steel Washer Options

|

||||

Properties and application parameters shown throughout this data sheet are typical. Your specific application should not be undertaken without independent study and evaluation for suitability. For specific application recommendations consult QUEST. Failure to select proper sealing products could result in property damage and/or serious personal injury. Specifications are subject to change without notice; this edition cancels all previous issues.

QUESTGUARD TM TYPE D Fabric-Reinforced Phenolic

(API Ring Joint) - insulang ring joint gaskets fit the ring groove of Ring Type Joint flanges. The Type D gasket, made of fabric-reinforced phenolic, matches ASA (ANSI) gasket dimensions. Properes are similar to phenolic flat central gaskets and are available in basic octagonal shapes; oval shapes can be requested. The kit includes a Minlon isolaon sleeve and washer set, plus zinc-plated SAE steel washers. Standard kits come as single washer sets; double washer kits are available on request.

| Isolating Gasket Specification | ||||||

|---|---|---|---|---|---|---|

| Grade | Description | Water Absorption % |

Tensile Strength PSI |

Compression Strength PSI |

Dielectric Values VPM |

Max. Operating Continuous |

| XP | Phenolic | 1.5 | 18,000 | 45,000 | 600 | 266 °F |

| Isolating Sleeve and Washer Specification | ||||

|---|---|---|---|---|

| Material | Dielectric Strength volts/mil |

Water Absorption % |

Max Continuous Operating Temperature |

|

| Minlon | 1,200 | 0.22 | 250°F | 41°C |

Properties and application parameters shown throughout this data sheet are typical. Your specific application should not be undertaken without independent study and evaluation for suitability. For specific application recommendations consult QUEST. Failure to select proper sealing products could result in property damage and/or serious personal injury. Specifications are subject to change without notice; this edition cancels all previous issues.

QUESTGUARD TM NP Ntirle faced Phenolic

The Nitrile Faced Phenolic Isolating gasket kit provides electrical flange isolation and corrosion control for pipes with water, wastewater, gas, natural gas, oil, and hydrocarbon media up to 175°F (79°C).

Available for flat face (Type E) and raised face (Type F) flanges from 1/2" to 24", ANSI 150-300#.

The gasket has a Phenolic retainer with Nitrile rubber on both sides. The kit includes a Minlon isolation sleeve and washer set, plus zinc-plated SAE steel washers. Standard kits come as single washer sets; double washer kits are available on request

| Isolating Gasket Specification | ||||||

|---|---|---|---|---|---|---|

| Grade | Description | Water Absorption % |

Tensile Strength PSI |

Compression Strength PSI |

Dielectric Values VPM |

Max. Operating Continuous |

| XP | Nitrile Phenolic | 1.5 | 18,000 | 45,000 | 600 | 266 °F |

| Isolating Sleeve and Washer Specification | ||||

|---|---|---|---|---|

| Material | Dielectric Strength volts/mil |

Water Absorption % |

Max Continuous Operating Temperature |

|

| Minlon | 1,200 | 0.22 | 250°F | 41°C |

Properties and application parameters shown throughout this data sheet are typical. Your specific application should not be undertaken without independent study and evaluation for suitability. For specific application recommendations consult QUEST. Failure to select proper sealing products could result in property damage and/or serious personal injury. Specifications are subject to change without notice; this edition cancels all previous issues.