Teflon Thread Seal

24B Joint Sealant Expanded PTFE Joint Sealant

Description and Applications

TEADIT® 24B is made from 100% pure, expanded, virgin PTFE. The whole production process is subject to strict quality control, registered under DIN EN ISO 9001.

Because of the excellent thermal and chemical resistance of TEADIT® 24B, it can be used in a wide variety of static applications in nearly all kinds of industry. The exceptional malleability of expanded PTFE can compensate for out-of-parallel and/or damaged sealing surfaces and allows use with stress sensitive connections and applications where only a limited flange load is available, e.g. plastic flanges, glass flanges, etc. Typical applications are the sealing of flanges, pump housings, compressors, hand- and manholes, air ducts, compensators, heat exchangers and many more.

Approvals

TA-Luft / DVGW / FDA (Incl. adhesive backing) / WRc / BAM / AREVA

Service Limits

| Temperature ºF (ºC) | Minimum: -450 (-268) |

|---|---|

| Short Term Max Temp: 600 (315) | |

| Pressure psi(bar) | 2900 (200) |

| pH | Minimum: 0 |

| Maximum: 14 |

Roll Availability

| Width (in) | 1/8" | 3/16" | 1/4" | 3/8" | 1/2" | 5/8" | 3/4" | 1" |

|---|---|---|---|---|---|---|---|---|

| Thickness(in) | .059" | .079" | .098" | .118" | .158" | .236" | .276" | .197" |

| Spool Length (ft) | 50', 100', 500' | 75',150',750' | 50', 100', 500' | 25', 50', 250' | 15', 30', 150' | 15', 30', 150' | 15', 30', 100' | 15', 30', 75' |

| Other sizes are available upon request. | ||||||||

Datasheet 24SH

| Temperature | Continuous Service: -76°F to 446°F (-60°C to +230°C) |

|---|---|

| Short Term Max: 600° F (315° C) | |

| Pressure | Vacuum up to: 580 psi (40 bar) |

| Color | White |

| pH | 0-14* |

| Width (in) | 1/8" | 3/16" | 1/4" | 3/8" | 1/2" | 5/8" | 3/4" | 1" |

|---|---|---|---|---|---|---|---|---|

| Thickness(in) | .059" | .079" | .098" | .118" | .158" | .236" | .276" | .197" |

| Spool Length (ft) | 50', 100', 500' | 75',150',750' | 50', 100', 500' | 25', 50', 250' | 15', 30', 150' | 15', 30', 150' | 15', 30', 100' | 15', 30', 75' |

| Other sizes are available upon request. | ||||||||

Approvals

TA-Luft / Blow-Out-Test VDI 2200 / FDA / USP Plastic Class VI / WRc / BAM / AREVA

25BI ePTFE Tape Multi-Directionally Expanded PTFE Gasket Tape

Description and Applications

TEADIT® 25BI is a multidirectionally expanded gasket-tape, produced from 100% pure PTFE (Polytetrafluorethylen). The whole production process is subject to strictest quality control, registered under ISO 9001.

TEADIT® 25BI – due to its excellent malleability and adaptability – is particularly well suited to compensate for irregularities or damages on the sealing areas, as well as for all stress-sensitive joints. A special manufacturing process results in almost equal tensile strength in both the longitudinal and cross direction. As a result of this, the material does not change its width under compression. This is in stark contrast to normal expanded PTFE tapes! TEADIT 25BI, because of this property, is extremely well suited as a gasket material for narrow sealing areas and in all applications where a defined gasket width (under load) is required. Typical applications are enamelled and glass flanges, heat exchangers, large flanges and containers, pressure vessels, suction filters and strainers, etc.

Approvals

TA-Luft / FDA

Service Limits

| Temperature ºF (ºC) | Minimum: -450 (-268) |

|---|---|

| Short Term Max Temp: 600 (315) | |

| Pressure psi(bar) | 2900 (200) |

| pH | Minimum: 0 |

| Maximum: 14 |

Roll Availability

| Width (in) | 1/2", 3/4", 1" | 1 1/2" | 2" |

|---|---|---|---|

| Thickness(in) | 1/16", 1/8", 1/4" | 1/8", 1/4" | 1/4" |

| Spool Length (ft) | 15', 25', 50' | ||

| Other sizes are available upon request. | |||

Datasheet 24SH

| Typical Physical Properties: | |

|---|---|

| Temperature | Minimum: -450°F (-268°C) |

| Maximum Service: 500° F (260° C) | |

| Short Term Max: 600° F (310° C) | |

| Pressure | Vacuum up to: 2900 psi (200 bar) |

| Color | White |

| pH | 0-14* |

| Compressibility | 70% (ASTM F36) |

| Recovery | 10% (ASTM F36) |

| *except molten alkali metals and elemental flourine at high temperature and pressure | |

Approvals

TA-Luft / FDA / EU 1935/2004 / WRc

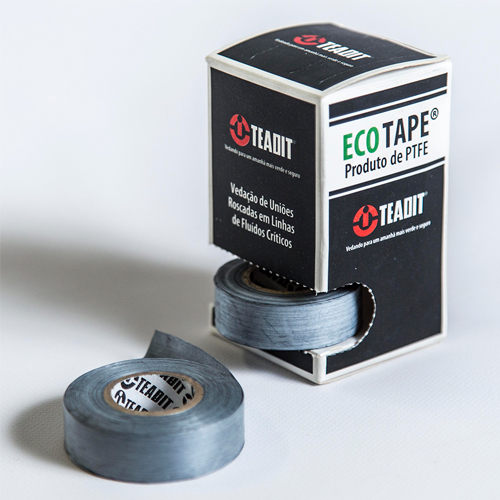

EcoTape-LE Thread seal tape made from Expanded PTFE combined with Graphite

Description and Applications

ECOtape-LE® is manufactured to provide an advanced structural matrix which incorporates Graphite into the Expanded PTFE. Due to the excellent properties of PTFE and graphite, this combination ensures a wide degree of chemical resistance, low coefficient of friction, excellent heat dissipation due to the high thermal conductivity of graphite and superior mechanical resistance.

Our unique manufacturing process provides the final product a high degree of integrity proven to supply the best sealing solution for thread seal tape.

- ZERO Emissions

- ENVIRONMENTAL Protection

Supply

| Width | 5/8 in (16 mm) |

|---|---|

| Length | 82 ft (25 m) |

Service Limits

| Temperature | Minimum: -400°F (-240°C) |

|---|---|

| Maximum: 518°F (270°C) | |

| Short Term Max: 590° F (310° C) | |

| Pressure | Vacuum up to: 2900 psi (200 bar) |

| pH | 0-14 |