Teflon and Gylon Sheet

Description:

Teflon is the most widely used plastic for industrial sealing. The only products that chemically attack Teflon is liquid alkaline metals and free fluorine.

Teflon gaskets are used in services where it is necessary to have a high chemical resistance.

Teflon also has excellent properties for electrical insulation, anti-stick, impact resistance and low friction coefficient.

- Good Temperature

- Excellent electrical Insulation

- Excellent Anti-Stick

Major characteristics include:

TF 1500 Virgin PTFE Sheet

Description and Applications

Style TF1500 PTFE (polytetrafluoroethylene) is a high molecular weight polymer and one of the most versatile plastics known to man. Style 1500 virgin PTFE sheet can handle virtually all chemicals in the 0-14 pH range with the exception of molten alkali metals and elemental fluorine. It is suitable for service at temperatures from the cryogenic range up to 500°F.

This style is particularly recommended for applications in the food and beverage industry where high purity materials are required. It is also used where contamination or discoloration of flow media cannot be tolerated.

Datasheet available upon request, please contact QUEST.

Service Limits

| Temperature ºF (ºC) | Minimum: -328(-200) |

|---|---|

| Maximum: 500 (260) | |

| Availability | 48"x48" |

| 60"x60" | |

| 48"or 60" wide continuous rolls | |

| Thickness | 1/64", 1/32", 1/16", 3/32", 1/8", 3/16", 1/4" |

| Color | White |

TF 1525 25% Glass Filled PTFE

Description and Applications

Style TF1525 PTFE (polytetrafluoroethylene) is a high molecular weight polymer and one of the most versatile plastics known to man. This PTFE sheet is filled with 25% glass fibers by weight. The filled material significantly reduces cold flow and creep and increases wear resistance compared to unfilled PTFE sheet. It can handle a very broad range of chemicals with the exception of molten alkali metals and elemental fluorine. This style is suitable for service at temperatures from the cryogenic range up to 500°F.

Datasheet available upon request, please contact QUEST.

Service Limits

| Temperature ºF (ºC) | Minimum: -328(-200) |

|---|---|

| Maximum: 500 (260) | |

| Availability | 48"x48" |

| 60"x60" | |

| 48"or 60" wide continuous rolls | |

| Thickness | 1/64", 1/32", 1/16", 3/32", 1/8", 3/16", 1/4" |

| Color | White |

| Typical Physical Properties: | |

|---|---|

| Tensile Strength at 73ºF - ASTM D638-61T | 2000-3000 psi |

| Elongation - ASTM D638-61T | D55.5 |

| Dielectric Strength in Air - ASTM D257-61 | 235 volts/mil. |

TF 1550 Mechanical Grade PTFE Sheet

Description and Applications

Style TF1550 PTFE (polytetrafluoroethylene) is a high molecular weight polymer and one of the most versatile plastics known to man. This sheet can handle virtually all chemicals in the 0-14 pH range with the exception of molten alkali metals and elemental fluorine. It is suitable for service at temperatures from the cryogenic range up to 500°F. This sheet is particularly recommended for applications in the industrial and process industries where high purity materials are not required. It is more economical than virgin PTFE sheet and the physical properties are only somewhat less than those of virgin PTFE.

Datasheet available upon request, please contact QUEST.

Service Limits

| Temperature ºF (ºC) | Minimum: -328(-200) |

|---|---|

| Maximum: 500 (260) | |

| Availability | 48"x48" |

| 60"x60" | |

| 48"or 60" wide continuous rolls | |

| Thickness | 1/64", 1/32", 1/16", 3/32", 1/8", 3/16", 1/4" |

| Color | White |

| Typical Physical Properties: | |

|---|---|

| Tensile Strength at 73ºF - ASTM D638-61T | 1500-2400 psi |

| Elongation - ASTM D638-61T | 75-200% |

| Dielectric Strength in Air - ASTM D257-61 | 450 volts/mil. |

Gylon Epix®

GYLON EPIX® Style 3500 Gaskets - PTFE with Silica Filler

PTFE Gasketing with Silica Filler for Aggressive Media

GYLON EPIX® Style 3500 is a high performance, silica filled PTFE gasket sheet material designed for use with strong acids, solvents, hydrocarbons, and other aggressive media. GYLON EPIX® Style 3500 withstands a wide range of chemicals for extended service in a wide variety of applications.

GYLON EPIX® will provide superior functional performance by combining the traditional attributes of GYLON® with an innovative surface design. It offers a broader range of applications than traditional PTFE gaskets used in worn and pitted flanges. In addition, GYLON EPIX® delivers the tight sealing and load retention properties of 1/16” (1.6mm) and the conformability of 1/8” (3.2mm). The hexagonal profile provides improved compressibility and recovery. The profiled surface reduces the contact area during initial compression to concentrate the compressive force of the flange for improved sealability.

FEATURES AND BENEFITS

- One thickness does the job of two

- Seal performance and load retention equal of 1/16” (1.6mm)

- Compressibility and forgiveness/conformability of 1/8” (3.2mm)

- Patented hex profile creates superb sealing and ability to conform to imperfect flange surfaces

- Same material as traditional GYLON®

SPECIFICATIONS

- Available in sheet or cut gasket form

- PTFE with silica filler

- Color: Fawn

- Available in 3/32” (2.4mm)

- Seal performance and load retention of 1/16 ” (1.6mm)

- Compressibility and forgiveness/conformability of 1/8” (3.2mm)

- Temperature

- Minimum: -450°F / -268°C

- Ideal Operating Limit: 400°F / 204°C

- Maximum: See Pressure/Temperature graph

- Pressure

- Ideal Operating Limit: 750 psig / 52 bar

- Maximum: See Pressure/Temperature graph

APPLICATIONS

- Strong acids (except hydrofluoric acid)

- Solvents

- Hydrocarbons

- Water

- Steam

- Chlorine

- Cryogenics

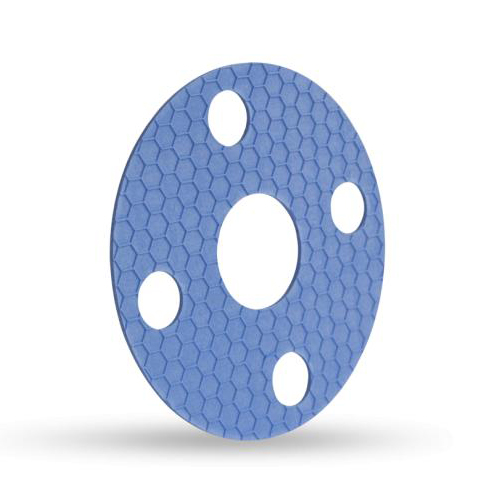

GYLON EPIX® Style 3504 Gaskets- PTFE with Aluminosilicate Microspheres

PTFE Gasketing with Aluminosilicate Microspheres for Moderate Media

GYLON EPIX® Style 3504 is a high performance, aluminosilicate microsphere filled PTFE sheet material designed for use in many acids, some caustics, as well as hydrocarbons, refrigerants, and more.

GYLON EPIX® will provide superior functional performance by combining the traditional attributes of GYLON® with an innovative surface design. It offers a broader range of applications than traditional PTFE gaskets that are used in worn and pitted flanges. In addition, GYLON EPIX® delivers the tight sealing and load retention properties of 1/16” (1.6mm) and the conformability of 1/8” (3.2mm). The hexagonal profile provides improved compressibility and recovery. The profiled surface reduces the contact area during initial compression to concentrate the compressive force of the flange for improved sealability.

FEATURES AND BENEFITS

- One thickness does the job of two

- Seal performance and load retention equal of 1/16”

- Compressibility and forgiveness/conformability of 1/8”

- Patented hex profile creates superb sealing and ability to conform to imperfect flange surfaces

- Same material as traditional GYLON®

SPECIFICATIONS

- Available in sheet or cut gasket form

- PTFE with aluminosilicate microspheres filler

- Color: Blue

- Available in 3/32” (2.4mm)

- Seal performance and load retention of 1/16 ” (1.6mm)

- Compressibility and forgiveness/conformability of 1/8” (3.2mm)

- Temperature

- Minimum: -450°F / -268°C

- Ideal Operating Limit: 400°F / 204°C

- Maximum: See Pressure/Temperature graph

- Pressure

- Ideal Operating Limit: 750 psig / 52 bar

- Maximum: See Pressure/Temperature graph

APPLICATIONS

- Many acids and some caustics

- Solvents

- Hydrocarbons

- Water

- Refrigerants

- Cryogenics

- Hydrogen peroxide

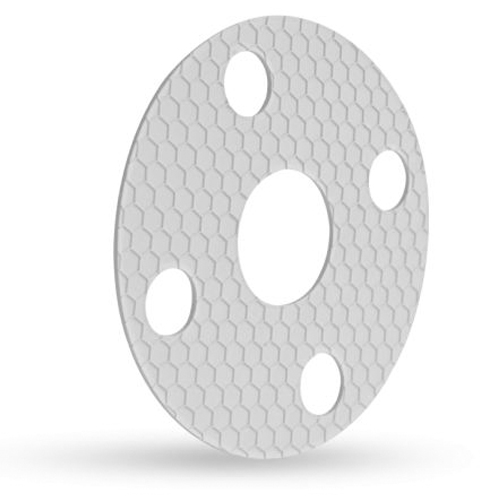

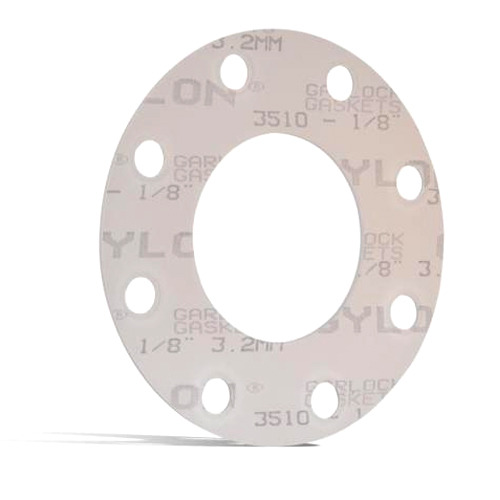

GYLON EPIX® Style 3510 Gaskets - PTFE with Barium Sulfate

PTFE Gasketing with Barium Sulfate Filler for Caustic Media

GYLON EPIX® Style 3510 is a high performance, barium sulfate filled PTFE gasketing material. GYLON EPIX® Style 3510 is designed for use where initiating and maintaining an extremely tight seal is critical; these applications include: strong caustics and moderate acids, chlorine, gases, water, steam, hydrocarbons and cryogenics.

GYLON EPIX® will provide superior functional performance by combining the traditional attributes of GYLON® with an innovative surface design. It offers a broader range of applications than traditional PTFE gaskets that are used in worn and pitted flanges. In addition, GYLON EPIX® delivers the tight sealing and load retention properties of 1/16” (1.6mm) and the conformability of 1/8” (3.2mm). The hexagonal profile provides improved compressibility and recovery. The profiled surface reduces the contact area during initial compression to concentrate the compressive force of the flange for improved sealability.

FEATURES AND BENEFITS

- One thickness does the job of two

- Seal performance and load retention equal of 1/16” (1.6mm)

- Compressibility and forgiveness/conformability of 1/8” (3.2mm)

- Patented hex profile creates superb sealing and ability to conform to imperfect flange surfaces

- Same material as traditional GYLON®

SPECIFICATIONS

- Available in sheet or cut gasket form

- PTFE with silica barium sulfate filler

- Color: Off-white

- Available in 3/32” (2.4mm)

- Seal performance and load retention of 1/16 ” (1.6mm)

- Compressibility and forgiveness/conformability of 1/8” (3.2mm)

- Temperature

- Minimum: -450°F / -268°C

- Ideal Operating Limit: 400°F / 204°C

- Maximum: See Pressure/Temperature graph

- Pressure

- Ideal Operating Limit: 750 psig / 52 bar

- Maximum: See Pressure/Temperature graph

APPLICATIONS

- Strong caustics

- Moderate acids

- Chlorine

- Gases

- Monomers

- Steam

- Hydrocarbons

- Cryogenics and aluminum fluoride

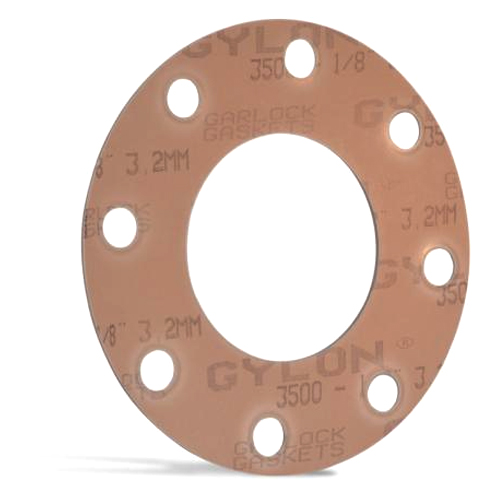

Gylon

GYLON® Style 3500 PTFE with Silica Filler Gasketing

PTFE with Silica Filler Gasketing

The GYLON® Style 3500 is a high performance, silica filled PTFE sheet material designed for use with strong acids, solvents, hydrocarbons, and other aggressive media.

FEATURES AND BENEFITS

- Tight seal

- Improved performance over conventional PTFE

- Reduced product loss and emissions

- Reduced creep relaxation

- Unique manufacturing process minimizes cold flow problems typical of skived and expanded PTFE sheets

- Excellent bolt torque retention

- Withstands a wide range of chemicals for extended service life in a wide variety of applications

- Offers some of the largest sheet sizes in the industry

- Improved material utilization reduces waste

- Branding and color coding reduces misapplication

- Will not support flame

- Will not support bacterial growth

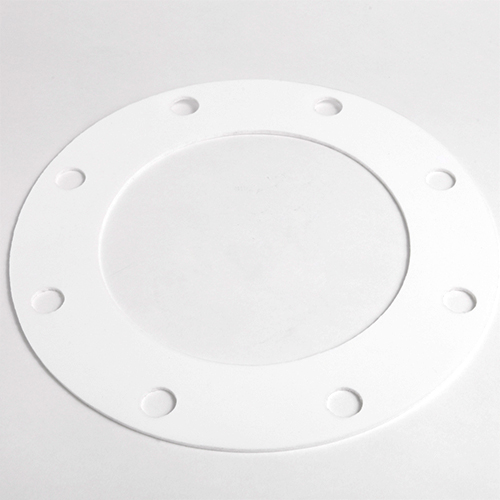

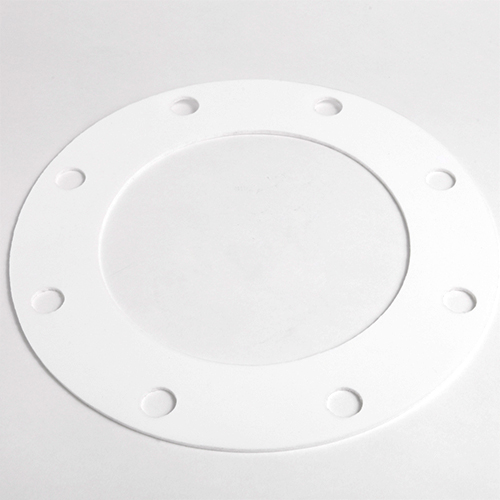

SPECIFICATIONS

- Available in sheet or cut gasket form

- PTFE with silica

- Color: Fawn

- Available in Full face or ring

- Available for 150 lb or 300 lb

- Available in 1/16 inch or ⅛ inch

- Meets ABS, FDA and USDA specifications

- Min. Temperature: -450°F / -268°C

- Max. Temperature: 500°F / 260°C

- Max. Pressure: 1200 PSI / 83 bar

- Maximum PxT 1/16: 350,000 °F x PSIG / 12,000 bar x °C

- Maximum PxT 1/8: 250,000 °F x PSIG / 8,600 bar x °C

APPLICATIONS

- Strong acids (except hydrofluoric acid)

- Solvents

- Hydrocarbons

- Water

- Steam

- Chlorine

- Cryogenics

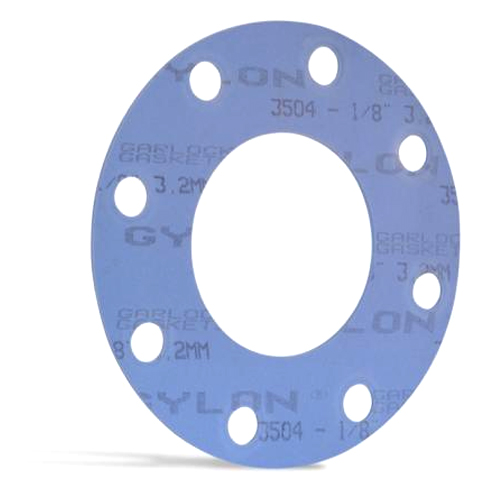

GYLON® Style 3504 PTFE with Aluminosilicate Microspheres Gasketing

PTFE with Aluminosilicate Microspheres Gasketing

The GYLON® Style 3504 gasket is made of PTFE with aluminosilicate microspheres. It is designed for use in many acids, some caustics, hydrocarbons, refrigerants, and more.

FEATURES AND BENEFITS

- Tight seal

- Improved performance over conventional PTFE

- Reduced product loss and emissions

- Reduced creep relaxation

- Unique manufacturing process minimizes cold flow problems typical of skived and expanded PTFE sheets

- Excellent bolt torque retention

- Withstands a wide range of chemicals for extended service life in a wide variety of applications

- Offers some of the largest sheet sizes in the industry

- Improved material utilization reduces waste

- Branding and color coding reduces misapplication

- Will not burn

- Will not support bacterial growth

SPECIFICATIONS

- Available in sheet or cut gasket form

- PTFE with aluminosilicate microspheres

- Color: Blue

- Meets ABS, FDA and USP specifications

- Min. Temperature: -450°F / -268°C

- Max. Temperature: 500°F / 260°C

- Max. Pressure: 800 PSI / 55 bar

- Maximum PxT 1/16: 350,000 °F x PSIG / 12,000 bar x °C

- Maximum PxT 1/8: 250,000 °F x PSIG / 8,600 bar x °C

APPLICATIONS

- Many acids and some caustics

- Solvents

- Hydrocarbons

- Water

- Refrigerants

- Cryogenics

- Hydrogen peroxide

For oxygen service, specify “Style 3505 for oxygen service.”

GYLON® Style 3510 PTFE With Barium Sulfate Filler Gasketing

PTFE with Barium Sulfate Filler Gasketing Material

The GYLON® Style 3510 is a high performance, barium sulfate filled PTFE gasketing material. GYLON® 3510 PTFE gasket is designed for use in strong caustics and toxic chemicals, such as chlorine, ammonia, and phosgene, where initiating and maintaining an extremely tight seal is critical. In addition, the GYLON® 3510 provides exceptional performance in monomer services.

FEATURES AND BENEFITS

- Tighter seal

- Improved performance over conventional PTFE

- Reduced product loss and emissions

- Reduced creep relaxation

- Unique manufacturing process minimizes cold flow problems typical of skived and expanded PTFE sheets

- Excellent bolt torque retention

- Withstands a wide range of chemicals for extended service life in a wide variety of applications

- Offers some of the largest sheet sizes in the industry

- Improved material utilization reduces waste

- Branding and color coding reduces misapplication

- Will not support flame

- Will not support bacterial growth

SPECIFICATIONS

- Available in sheet or cut gasket form

- PTFE with barium sulfate

- Color: Off-white

- Meets ABS and FDA specifications

- Min. Temperature: -450°F / -268°C

- Max. Temperature: 500°F / 260°C

- Max. Pressure: 1200 PSI / 83 bar

- Maximum PxT 1/16: 350,000 °F x PSIG / 12,000 bar x °C

- Maximum PxT 1/8: 250,000 °F x PSIG / 8,600 bar x °C

APPLICATIONS

- Strong caustics

- Moderate acids

- Chlorine

- Gases

- Monomers

- Steam

- Hydrocarbons

- Cryogenics and aluminum fluoride

GYLON® Style 3540 Microcellular PTFE Gasketing

Microcellular PTFE Gasketing for Glass-lined Equipment.

The GYLON® Style 3540 gasket is a highly compressible, microcellular PTFE gasketing material designed to compress and conform to irregular or damaged surfaces, making it suitable for flanges that generate lower compressive stresses, such lined flanges and equipment.

FEATURES AND BENEFITS

- Tight seal

- Highly compressible PTFE seals under low bolt load

- Compressible material conforms to surface irregularities, especially on warped, pitted, or scratched flanges

- Reduced cold flow and creep

- Pure PTFE withstands a wide range of chemicals

- Soft PTFE can be cut easily from larger sheets, reducing inventory costs and expensive downtime

- Will not support flame

- Will not support bacterial growth

SPECIFICATIONS

- Available in sheet or cut gasket form

- Microcellular PTFE

- Color: White

- Meets FDA specifications

- Min. Temperature: -450°F / -268°C

- Max. Temperature: 500°F / 260°C

- Max. Pressure: 1200 PSI / 55 bar

- Maximum PxT 1/16: 350,000 °F x PSIG / 12,000 bar x °C

- Maximum PxT 1/8: 250,000 °F x PSIG / 8,600 bar x °C

APPLICATIONS

- Suitable for many non-metallic flanges*

- Strong caustics

- Strong acids

- Hydrocarbons

- Chlorine

- Cryogenics

- Glass-lined equipment

*For flat face flanges, a minimum compressive stress of 1,500 psi is recommended on the contacted gasket area for 150 psig liquid service. Consult with the flange manufacturer to confirm that adequate compressive stress is available.

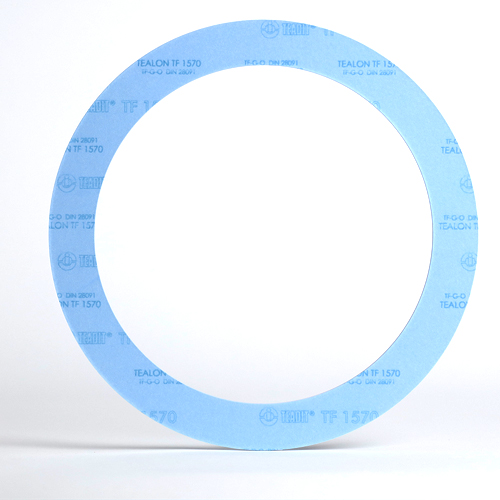

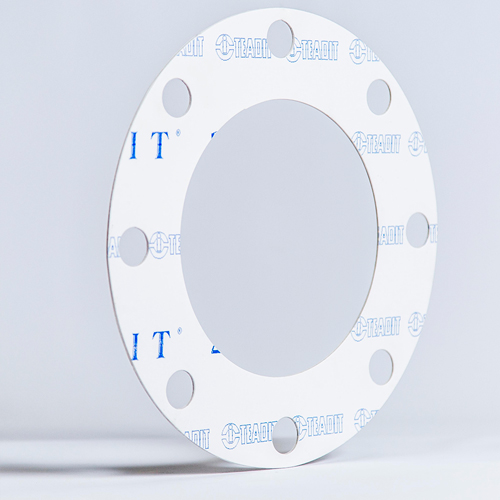

Tealon TF1570 Restructured PTFE with Glass Spheres

Description and Applications

Tealon TF1570 is filled with glass microspheres and is suitable for aggressive chemical applications. It meets FDA conformance for service within food and pharmaceutical applications. TF1570 is the preferred material for fragile flanges, glass lined equipment or other applications that require higher compressibility.

Approvals: DVGW - TA-Luft - FDA

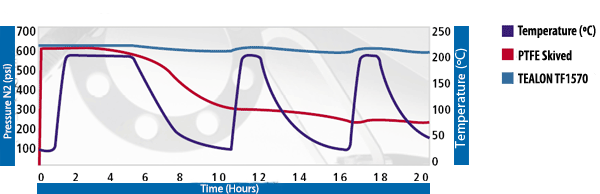

Hot Compression Test

This performance test measures the behavior of rPTFE and PTFE gaskets in a real world environment. The chart below shows a comparison between conventionally skived PTFE and Tealon. The gaskets we tested simulated a real world application including thermo-cycling. The skived PTFE gasket showed a very high leak rate, losing 60% of its initial pressure by the end of the test.

The Tealon® gasket lost only 6% of its initial pressure by the end of the test and showed a leak 10 times less than that of the skived PTFE gasket. The pictures below, show the gaskets after the test and exhibit the dimensional stability of Tealon as compared to the noticeable creep of the skived PTFE gasket.

Tealon™ TF1570 Datasheet

| Availability | 60" x 60" |

|---|---|

| Temperature ºF (ºC) | Minimum: -450(-200) |

| Maximum: 500 (260) | |

| Pressure | Maximum Service: 800 psi (55 bar) |

| Thickness | 1/32", 1/16", 3/32", 1/8", 1/4" |

| Color | Blue |

| pH | 0-14 |

| Typical Physical Properties: | |

|---|---|

| Compressibility - ASTM F36 | 25 - 40% |

| Recovery - ASTM F36 M | 30% |

| Tensile Strength - ASTM F152 | 2030 psi(14 N/mm2) |

| Specific Gravity - ASTM D792 | 1.70 g/cm3 |

| Creep Relaxation - ASTM F38 | 40% |

| Sealability - ASTM F37 A | 0.12ml/h |

| Sealability - DIN 3535 | 0.15 cm3/min |

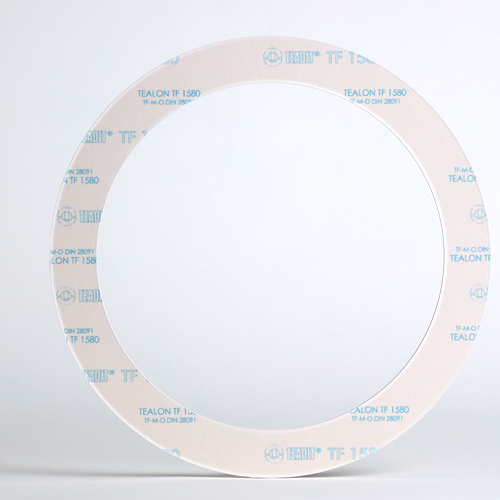

Tealon TF1580 Restructured PTFE with Barium Sulfate

Description and Applications

Tealon TF1580 is filled with barium sulfate and is suitable for strong caustic fluids. It meets FDA conformance for service within food and pharmaceutical applications. 1580 can be used in a wide range of applications due to its vast resistance to most chemical products. It is compatible with strong acids along with strong caustics, making it the most diverse material within the Tealon family. With the off-white color of 1580, this material is also suitable for processes where contamination is not tolerated. Tealon 1580 meets and has been approved by BAM for oxygen service.

Approvals: DVGW — TA-Luft — FDA — BAM — Chlorine Institute

Thermo-Cycling Leak Test

Temperature cycles from 30º C to 200ºC, with seating stress of 5000psi and using a gasket thickness of 1/8".

Service Limits

| Availability | 60" x 60" |

|---|---|

| * 59"x59" is available upon request. | |

| Temperature ºF (ºC) | -450 to 500 ºF (-268 to 260 ºC) |

| Maximum: 500 (260) | |

| Pressure | Maximum Service: 800 psi (55 bar) |

| Thickness | 1/32", 1/16", 3/32", 1/8", 1/4" |

| Color | Off-White |

| Typical Physical Properties: | |

|---|---|

| Compressibility - ASTM F36 | 4 - 10% |

| Recovery - ASTM F36 M | 40% |

| Tensile Strength - ASTM F152 | 2030 psi(14 N/mm2) |

| Creep Relaxation - ASTM F38 B | 15% |

| Sealability - ASTM F37 A | 0.04ml/h |

Tealon™ TF1580 Datasheet

| Availability | 60" x 60" |

|---|---|

| * 59"x59" is available upon request. | |

| Thickness | 1/32", 1/16", 3/32", 1/8", 1/4", 2mm |

| Temperature ºF (ºC) | Minimum: -450(-268) |

| Maximum: 500 (260) | |

| Pressure | Maximum Service: 1200 psi (83 bar) |

| Color | Off-White |

| pH | 0-14 |

| Typical Physical Properties: | |

|---|---|

| Compressibility 5000 psi - ASTM F36 M | 4 - 10% |

| Recovery - ASTM F36 M | 40% |

| Tensile Strength - ASTM F152 | 2030 psi(14 N/mm2) |

| Specific Gravity - ASTM D792 | 2.90 g/cm3 |

| Creep Relaxation - ASTM F38B | 15% |

| Sealability - ASTM F37 A | 0.04 ml/h |

| Sealability - DIN 3535 | < 0.015 cm3/min |

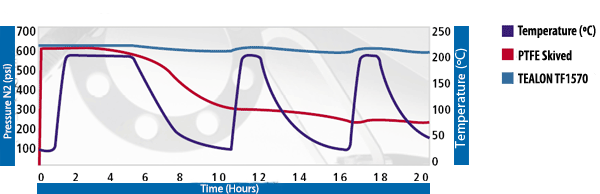

Hot Compression Test

This performance test measures the behavior of rPTFE and PTFE gaskets in a real world environment. The chart below shows a comparison between conventionally skived PTFE and Tealon. The gaskets we tested simulated a real world application including thermo-cycling. The skived PTFE gasket showed a very high leak rate, losing 60% of its initial pressure by the end of the test.

The Tealon® gasket lost only 6% of its initial pressure by the end of the test and showed a leak 10 times less than that of the skived PTFE gasket. The pictures below, show the gaskets after the test and exhibit the dimensional stability of Tealon as compared to the noticeable creep of the skived PTFE gasket.

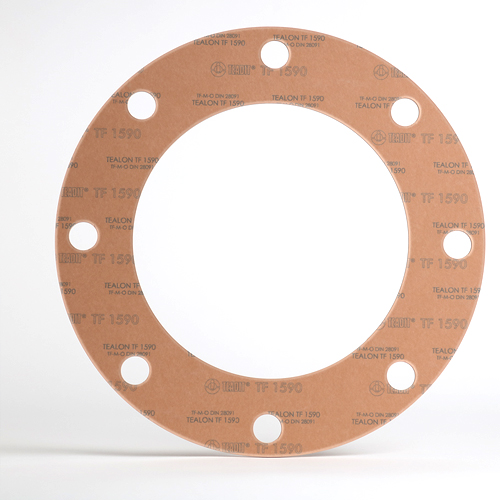

Tealon TF1590 Restructured PTFE with Silica

Description and Applications

Tealon TF1590 is filled with silica and meets a wide range of applications. It is suitable for general service, strong acids and moderate caustic solutions. It meets FDA conformance for service within food and pharmaceutical applications. TF1590 has easily passed the Hot Compression Test with outstanding results.

Approvals: DVGW — TA-Luft — FDA — Chlorine Institute

Hot Compression Test

This performance test measures the behavior of rPTFE and PTFE gaskets in a real world environment. The chart below shows a comparison between conventionally skived PTFE and Tealon. The gaskets we tested simulated a real world application including thermo-cycling. The skived PTFE gasket showed a very high leak rate, losing 60% of its initial pressure by the end of the test.

The Tealon® gasket lost only 6% of its initial pressure by the end of the test and showed a leak 10 times less than that of the skived PTFE gasket. The pictures below, show the gaskets after the test and exhibit the dimensional stability of Tealon as compared to the noticeable creep of the skived PTFE gasket.

Thermo-Cycling Leak Test

Temperature cycles from 30º C to 200ºC, with seating stress of 5000psi and using a gasket thickness of 1/8".

Service Limits

| Availability | 60" x 60" |

|---|---|

| * 59"x59" is available upon request. | |

| Temperature ºF (ºC) | -450 to 500 ºF (-268 to 260 ºC) |

| Pressure | Maximum Service: 1200 psi (83 bar) |

| Thickness | 1/32", 1/16", 3/32", 1/8", 1/4" |

| Color | Fawn |

| Typical Physical Properties: | |

|---|---|

| Sealability - ASTM F37 A | 0.20ml/h |

| Creep Relaxation - ASTM F38 B | 18% |

| Compressibility - ASTM F36 M | 5 - 15% |

| Recovery Min - ASTM F36 M | 40% |

| Tensile Strength - ASTM F152 | 2030 psi |

Datasheet TF1590

| Availability | 60" x 60" |

|---|---|

| * 59"x59" is available upon request. | |

| Thickness | 1/32", 1/16", 3/32", 1/8", 1/4", 2mm |

| Temperature ºF (ºC) | Minimum: -450(-268) |

| Maximum: 500 (260) | |

| Pressure | Maximum Service: 1200 psi (83 bar) |

| Color | Fawn |

| pH | 0-14 |

| Typical Physical Properties: | |

|---|---|

| Compressibility 5000 psi - ASTM F36 M | 5 - 15% |

| Recovery - ASTM F36 M | 40% |

| Tensile Strength - ASTM F152 | 2030 psi(14 N/mm2) |

| Specific Gravity - ASTM D792 | 2.10 g/cm3 |

| Creep Relaxation - ASTM F38B | 18% |

| Sealability - ASTM F37 A | 0.20 ml/h |

| Sealability - DIN 3535 | < 0.015 cm3/min |

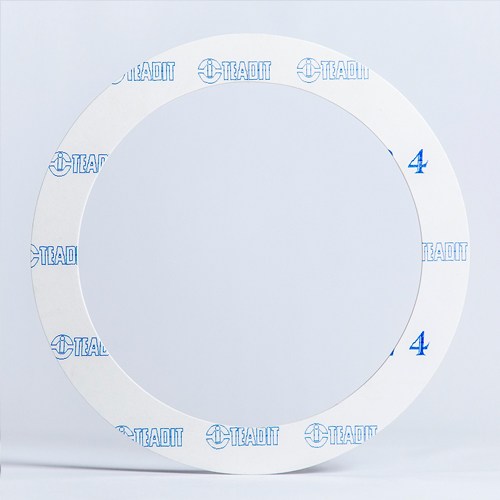

24SH ePTFE Gasket Sheet 100% Expanded PTFE Sheet

Description and Applications

TEADIT® 24SH is a large gasket sheet produced from 100% pure, multi-directionally expanded PTFE.

Universally employable gasket sheet for all applications. It is suitable for all types of flanges, nearly all media, a wide temperature range and for applications with the toughest demands on purity. It is inherently clean and non-toxic.

Gaskets of multi-directionally expanded PTFE have exceptional mechanical strength which allows operation with minimal creep at elevated temperatures.

The excellent malleability of TEADIT® 24SH makes repairing small damage and/or irregularities of the sealing area (flange surface) unnecessary.

Gaskets cut from TEADIT® 24SH are dimensionally stable, i. e. they do not get wider when compressed. This allows narrow flange faces to be sealed safely.

TEADIT® 24SH is quick and simple to install. The used gasket can be removed easily and without residue.

Approvals

TA-Luft / Blow-Out-Test VDI 2200 / FDA / USP Plastic Class VI / WRc / BAM / AREVA

Hot Compression Test

This performance test measures the behavior of rPTFE and PTFE gaskets in a real world environment. The chart below shows a comparison between conventionally skived PTFE and Tealon. The gaskets we tested simulated a real world application including thermo-cycling. The skived PTFE gasket showed a very high leak rate, losing 60% of its initial pressure by the end of the test.

The Tealon® gasket lost only 6% of its initial pressure by the end of the test and showed a leak 10 times less than that of the skived PTFE gasket. The pictures below, show the gaskets after the test and exhibit the dimensional stability of Tealon as compared to the noticeable creep of the skived PTFE gasket.

Temperature cycles from 30º C to 200ºC, with seating stress of 5000psi and using a gasket thickness of 1/8".

Service Limits

| Availability | 60" x 60" |

|---|---|

| *1/32", 3/32 available on special request | |

| Thickness | 1/4", 1/8", 1/16"*, 1mm, .5mm |

| Temperature ºF (ºC) | Minimum: -450 (-268) |

| Short Term Max Temp: 600 (315) | |

| Pressure psi(bar) | 2900 (200) |

| pH | Minimum: 0 |

| Maximum: 14 |

Datasheet 24SH

Approvals

TA-Luft / Blow-Out-Test VDI 2200 / FDA / USP Plastic Class VI / WRc / BAM / AREVA

| Temperature | Minimum: -450°F (-268°C) |

|---|---|

| Maximum Service: 500°F (260°C) | |

| Short Term Max: 600° F (315° C) | |

| Pressure | Vacuum up to: 2900 psi (200 bar) |

| Color | White |

| pH | 0-14 |

| Density | 0.9 g/cm3 |

| Typical Physical Properties: | |

|---|---|

| Compressibility 5000 psi - ASTM F36 M | 45% |

| Recovery - ASTM F36 M | 14% |

| Tensile Strength - ASTM F152 | > 20 MPa |

| Specific Leakage Rate L- VDI 2440 / TA LUFT | 2.6 X 10-7 |

| Stress Retention- DIN 52913 | 15 MPa |