SPECIFICATIONS

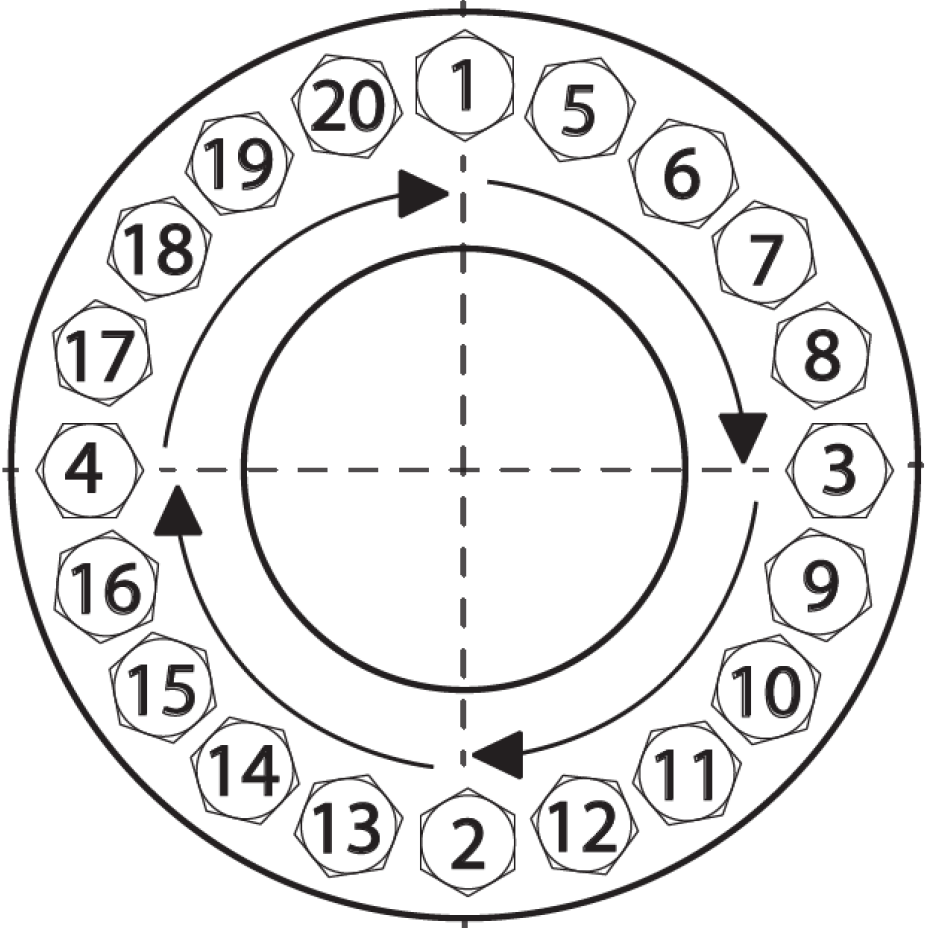

4 To 20 Hole, Bolt Torque Sequence

4 To 20 Hole, Bolt Torque Sequence

Number bolts or flange holes with a “marker” as shown in the diagram.

Install each bolt with their nuts, washers and hand tighten the nuts following the numerical sequence of the diagram. The flanges should be parallel and contacting uniformly across the gasket. If tools are used to bring the flanges together the maximum force should be equal or less than 10% of the target force. The stud length should have at least two threads protrude beyond the nut.

Steps:

- Tighten studs 1, 2, 3 and 4 with 30% of the final torque or force. Ensure the flanges are parallel.

- Tighten studs 1, 2, 3 and 4 with 60% of the final torque or force. Ensure the flanges are parallel.

- Tighten studs 1, 2, 3 and 4 with 100% of the final torque or force. Ensure the flanges are parallel.

- Tighten all studs with 100% of the final torque or force in a circular pass. Ensure the flanges are parallel.

- Repeat the fourth (4) step until the nuts no longer turn.

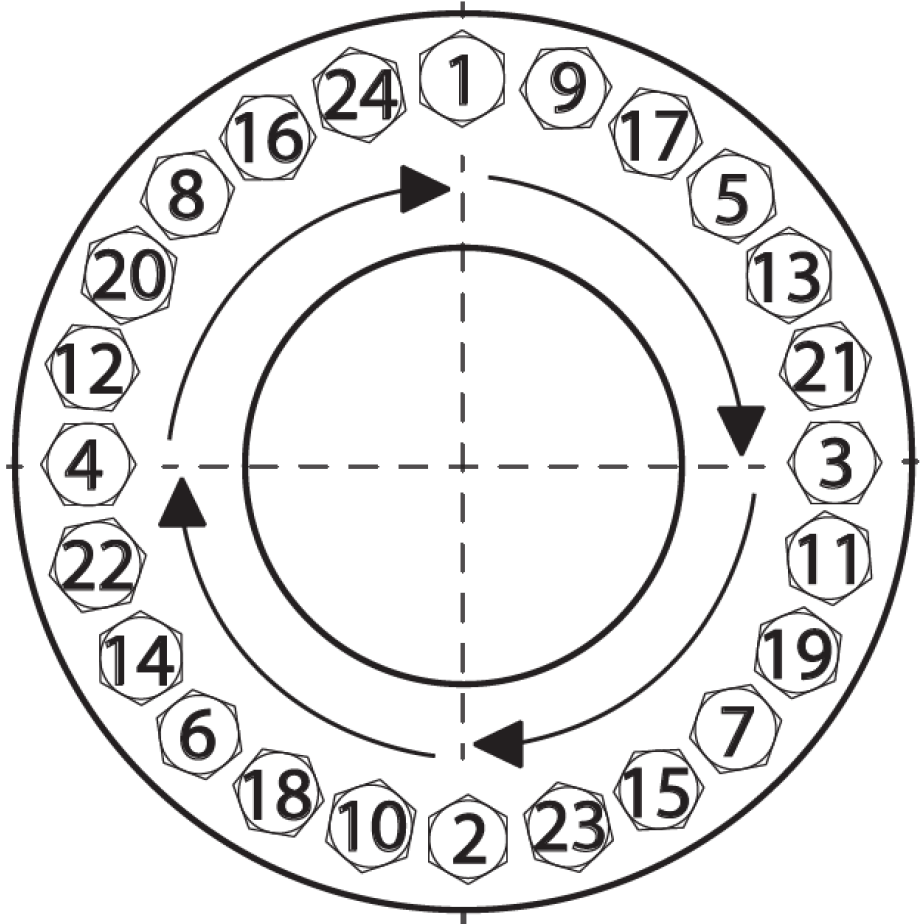

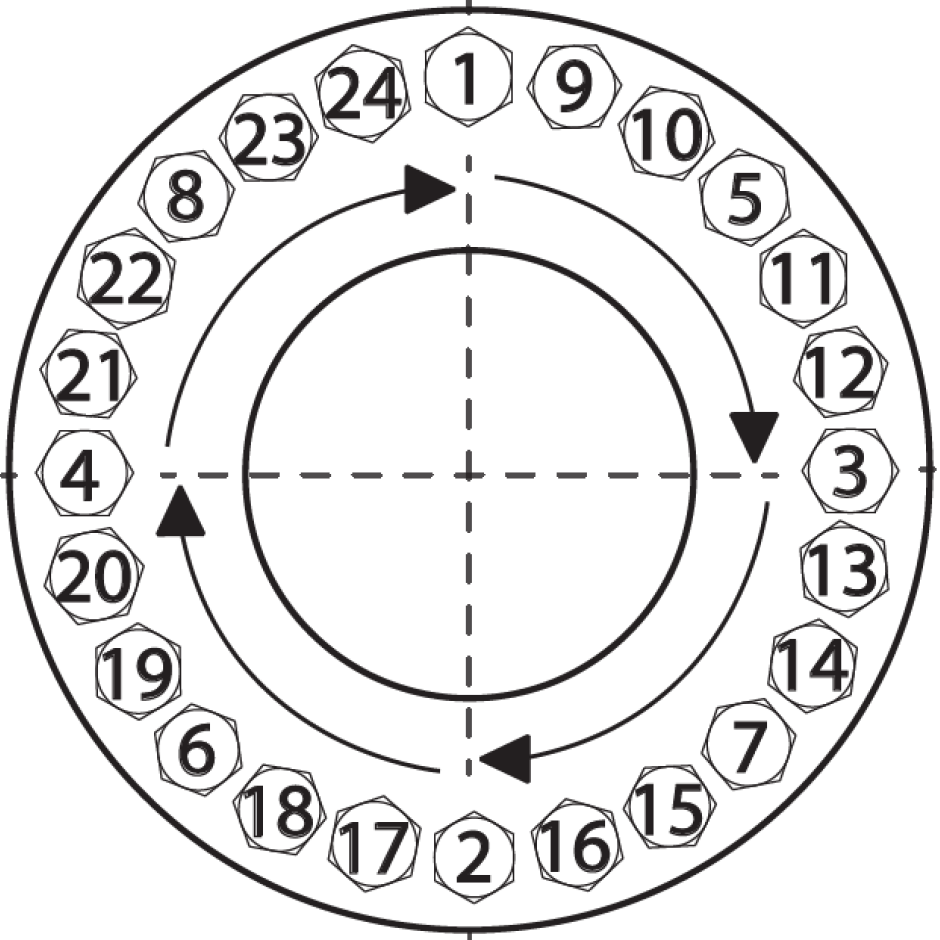

24 Hole, Bolt Torque Sequence

24 Hole, Bolt Torque Sequence

Number bolts or flange holes with a “marker” as shown in the diagram.

Install each bolt with their nuts, washers and hand tighten the nuts following the numerical sequence of the diagram. The flanges should be parallel and contacting uniformly across the gasket. If tools are used to bring the flanges together the maximum force should be equal or less than 10% of the target force. The stud length should have at least two threads protrude beyond the nut.

Steps:

- Tighten all studs in the numerical sequence as shown with 30% of the final torque or force. Ensure the flanges are parallel.

- Tighten all studs in the numerical sequence as shown with 60% of the final torque or force. Ensure the flanges are parallel.

- Tighten all studs in the numerical sequence as shown with 100% of the final torque or force. Ensure the flanges are parallel.

- Tighten all studs with 100% of the final torque or force in a circular pass. Ensure the flanges are parallel.

- Repeat the fourth (4) step until the nuts no longer turn.

24 Or More Hole, Bolt Torque Sequence

24 Or More Hole, Bolt Torque Sequence

Number bolts or flange holes with a “marker” as shown in the diagram.

Install each bolt with their nuts, washers and hand tighten the nuts following the numerical sequence of the diagram. The flanges should be parallel and contacting uniformly across the gasket. If tools are used to bring the flanges together the maximum force should be equal or less than 10% of the target force. The stud length should have at least two threads protrude beyond the nut.

Steps:

- Tighten studs 1, 2, 3, 4, 5, 6, 7 and 8 with 30% of the final torque or force. Ensure the flanges are parallel.

- Tighten studs 1, 2, 3, 4, 5, 6, 7 and 8 with 60% of the final torque or force. Ensure the flanges are parallel.

- Tighten studs 1, 2, 3, 4, 5, 6, 7 and 8 with 100% of the final torque or force. Ensure the flanges are parallel.

- Tighten all studs with 100% of the final torque or force in a circular pass. Ensure the flanges are parallel.

- Repeat the fourth (4) step until the nuts no longer turn.