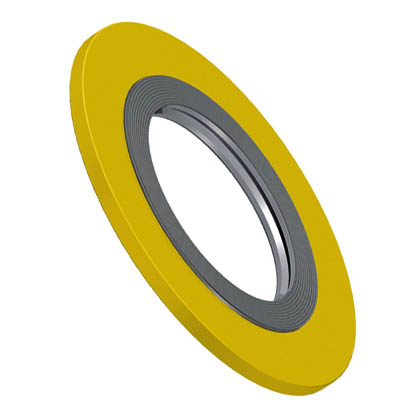

Spiral Wound Gasket

- Home

- Semi Metalic

- Spiral Wound(STYLE 913 and 913M)

STYLE 913 and 913M

Quest Metalflex Dimensions

Description

Quest Metalflex 913 Spiral-wound gaskets are made of a preformed metallic strip and a soft filler material (PTFE or graphite), wound together under pressure, and optionally with an inner and/or outer guide ring. The metal strip holds the filler, resulting in excellent mechanical resistance, resilience and recovery.

Construction

Style 913 is constructed with a metallic guide ring, metallic winding and a filler element. The winding is manufactured from metal in a complicated form of a spiral, in assembly with a filler material. The metallic Winding, of special profile, provides excellent resistance, compensating the changes in operational conditions such as: variations of pressure and temperature, vibrations, thermal shocks, etc. The filler materials fill the irregularities of the flanges, assuring an airtight seal. Its external guide ring has the function of centering the gasket in the flanges and gives the sealing elements additional resistance to the flow pressure, avoiding also excessive bolt torque.

Application / Service

For applications with high temperature variations (thermal cycling), and/or pressure variations, and/or flange rotation problems etc., gaskets with adequate residual stress (stress retention), flexibility and recovery are needed. Quest spiral-wound gaskets have been designed to meet these demanding requirements.

Quest Metalflex 913 for flanges ASME B16.5 follows rigorously the specifications from ASME B16.20.

Material Properties

| Filler Material | Max. Temperature |

|---|---|

| Mica Graphite |

232 C (450 F) |

| Flexible Graphite |

450 C (842 F)* |

| PTFE | 260 C (500 F) |

|

*Up to 650 C (1,200 F) with steam and under inert conditions Note: Depending on the combination between the Metallic Winding and the Filler, they range in vacuum to 10 000 PSI. |

|

Quest Metalflex 913-M

Description

Designed for elevated vacuum, pressures and temperatures, this Quest Metalflex 913-M is a Modified 913 with an internal ring that fills the space between the flanges, avoiding turbulence in the flow of the fluid or as a protection against corrosion or erosion. It is also used as a compression limit when the seating stress is greater than 30,000 psi (210 MPa).

Second, gaskets with PTFE filler have a tendency to inward buckle thus the use of an inner ring is recommended.

Construction, Application/Service, Material Properties

See Quest Metalflex 911

Quest Metalflex 911-T

Description

Double Jacketed bars are welded into the winding of a Metalflex 911 developed for shell and tube heat exchangers with several passes. The bars are manufactured in the same material and are plasma or spot welded to the winding. The thickness of the bar is normally a little less than the winding to reduce the seating force of the gasket. Metalflex 911-T has better sealability than conventional heat exchanger double-jacketed gaskets. Second, gaskets with PTFE filler have a tendency to inward buckle thus the use of an inner ring is recommended.

Construction, Application/Service, Material Properties

See Quest Metalflex 913

Quest Metalflex 914

Description

Style Metalflex 914 spiral wound gaskets are windings in non-circular forms like oval, rectangular and square with rounded corners, diamond, oblong or pear shaped.

Construction, Material Properties

See Quest Metalflex 911

Application/Service

Quest Metalflex 914 spiral wound gaskets are used in boiler handholes and manholes, equipment, engine head-gaskets and exhaust systems.

Tongue and Groove Flanges ASME B16.5

| A and B | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal Diameter | Dimensions of the Gasket - inches | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| large | Small | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Ie | Ee | Ie | Ee | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 1 | 1 3/8 | 1 | 1 3/8 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

Male and Female Flanges ASME B16.5

| C | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal Diameter | Dimensions of the Gasket - inches | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Class 150 to 1500 psi | Class 2500 psi | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Ie | Ee | Ie | Ee | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 1 | 1 3/8 | 1 | 1 3/8 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||